Water surface garbage automatic collection ship with garbage collection mechanism

A technology for automatic collection of water surface garbage, which is applied to motor vehicles, cleaning of open water surfaces, water conservancy projects, etc., can solve the problems of garbage waste and labor, and achieve the effects of reducing disturbance, improving picking up efficiency, and good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

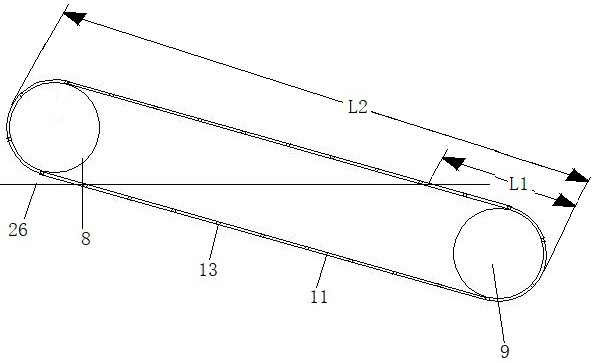

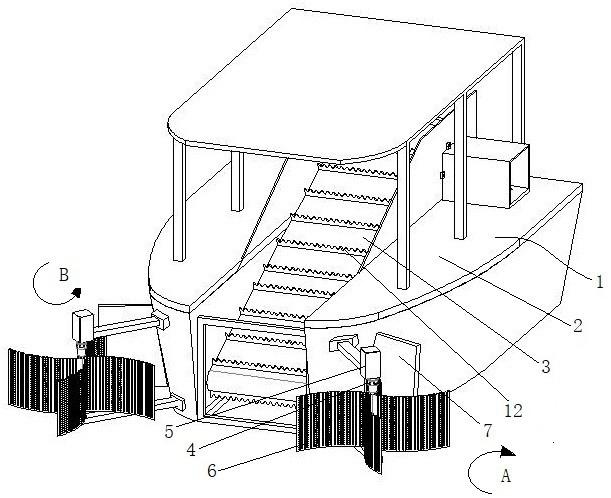

[0032] Embodiment one, see image 3 and figure 2 , an automatic surface garbage collection ship with a garbage collecting mechanism, comprising a hull 1 and a power mechanism driving the hull to walk, and the power mechanism is driven by an existing motor-driven propeller. The hull includes two pontoons 2 distributed along the left and right directions. The conveyer belt 3 that scrapes up the rubbish on the water surface is provided between two floating tanks. It is transported to the inclined setting with the front end low and the rear end high, and the rear end of the hull is provided with a garbage storage box to catch the garbage transported by the conveyor belt. The front end of the floating tank is provided with a garbage collection mechanism that pushes the garbage on the water surface on both sides of the hull towards the conveyor belt. The rubbish collection mechanism comprises a vertical shaft 4, a shaft drive motor 5 that drives the vertical shaft to rotate, and...

Embodiment 2

[0033] Embodiment two, the difference with embodiment one has two points:

[0034] One is that embodiment one is to prevent garbage from flowing backward by setting baffles to affect the collection effect, and this embodiment is:

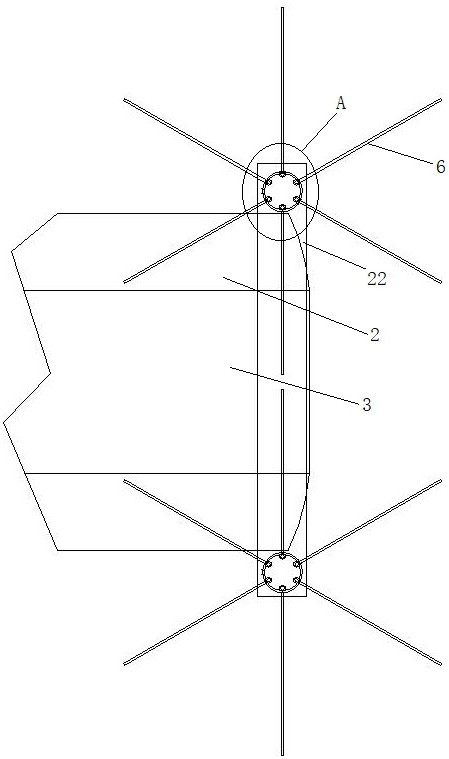

[0035] see figure 1 , Figure 4 , Figure 5 and Figure 6 , the vertical shaft is sleeved with a supporting ring 14 fixedly connected to the hull, and the upper end surface of the supporting ring is provided with a first planar section 15 and a first inclined plane section 16 which are sequentially connected end to end along the circumferential direction of the supporting ring. , the second plane section 17 and the second inclined plane section 18, the first plane section is located at the side of the supporting ring close to the hull, and the vertical rotation axis includes an upper section 19, a middle section and a lower section 20 connected together in sequence. The upper end is provided with an outer flange 21 and the outer flange is suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com