Shuttle goods shelf matched with shuttle vehicle

A shuttle car and shelf technology, which is applied in the field of shuttle storage, can solve the problems such as the inability to reduce the volume and self-weight of the shuttle car, and achieve the effects of a reasonable power supply mode, eliminating fire, and improving the volume and self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

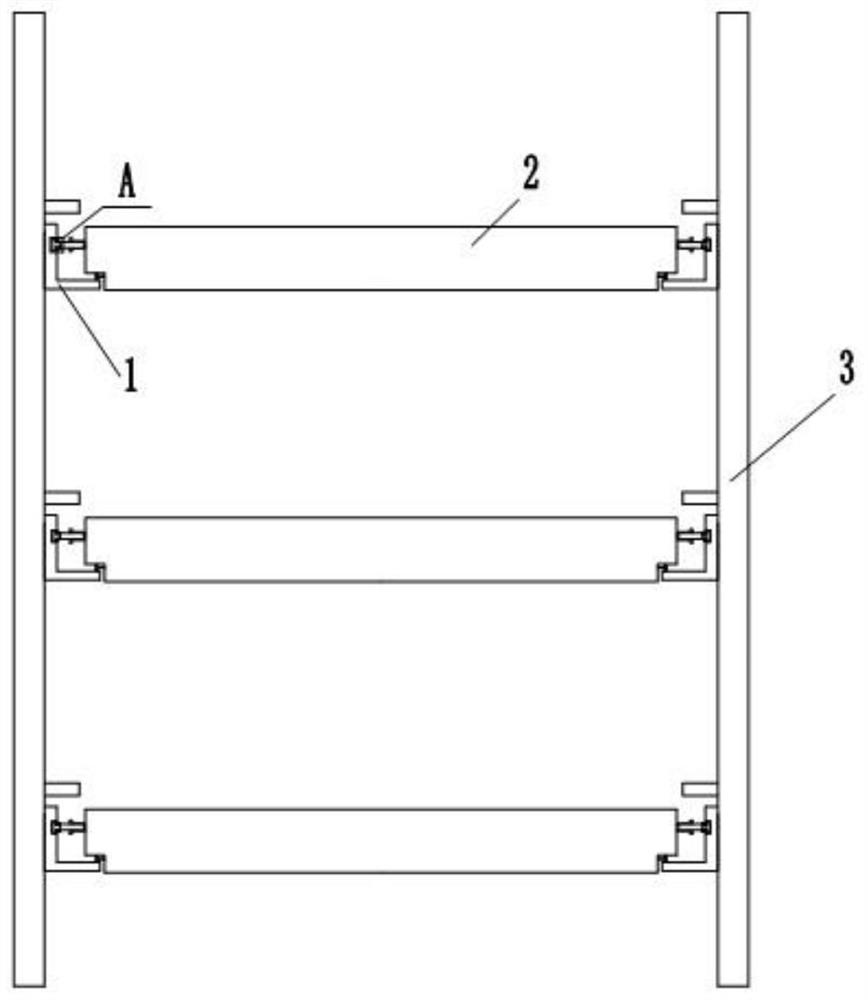

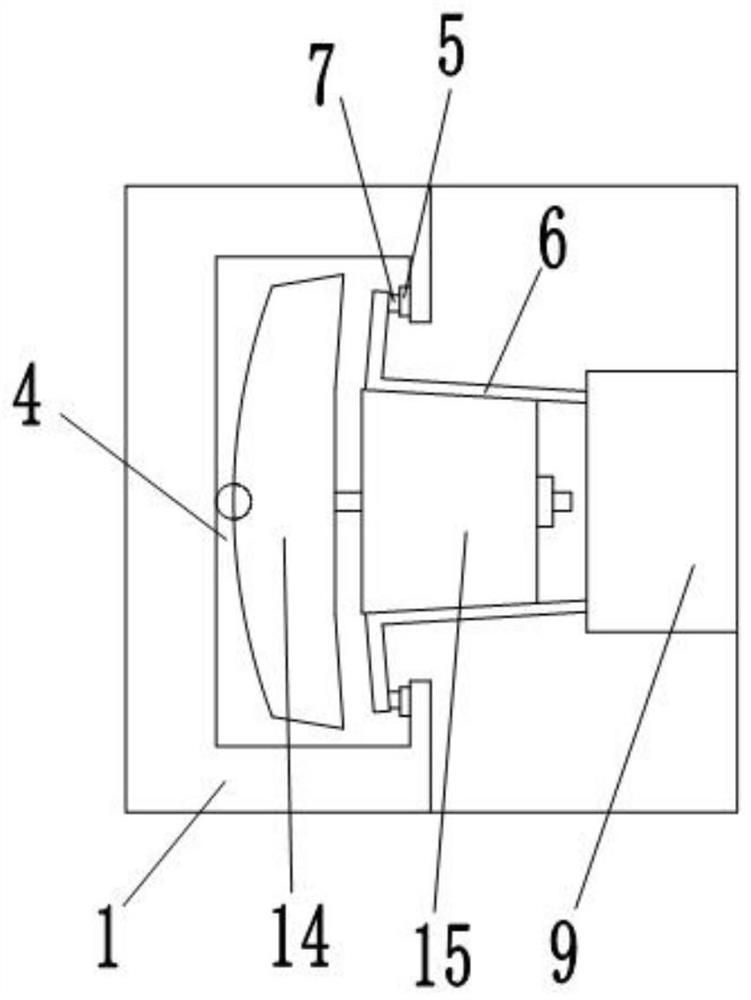

[0025] Such as Figure 1~2 Shown, the present invention is a kind of shuttle shelf that cooperates with the shuttle car, comprises the guide rail that cooperates with the shuttle car, is provided with three pairs of parallel guide rails 1 on the inner side of two adjacent columns 3, and the column 3 is provided with 10 rows (the accompanying drawings only Show any two adjacent rows). The guide rail 1 is made of stainless steel. The cross-section of the guide rail 1 is L-shaped as a whole. It is composed of a track part at the bottom of the guide rail and a side stopper perpendicular to the track part. The power supply tank 4 is arranged on the surface of the side stop part, which is processed by CNC . A pair of cargo carrying beams parallel to the guide rail 1 are arranged above the guide rail 1, and a polyurethane protective layer is provided on the surface of the cargo carrying beams. The groove shape of the power supply tank 4 is a lateral T shape, and two conductive bars...

Embodiment 2

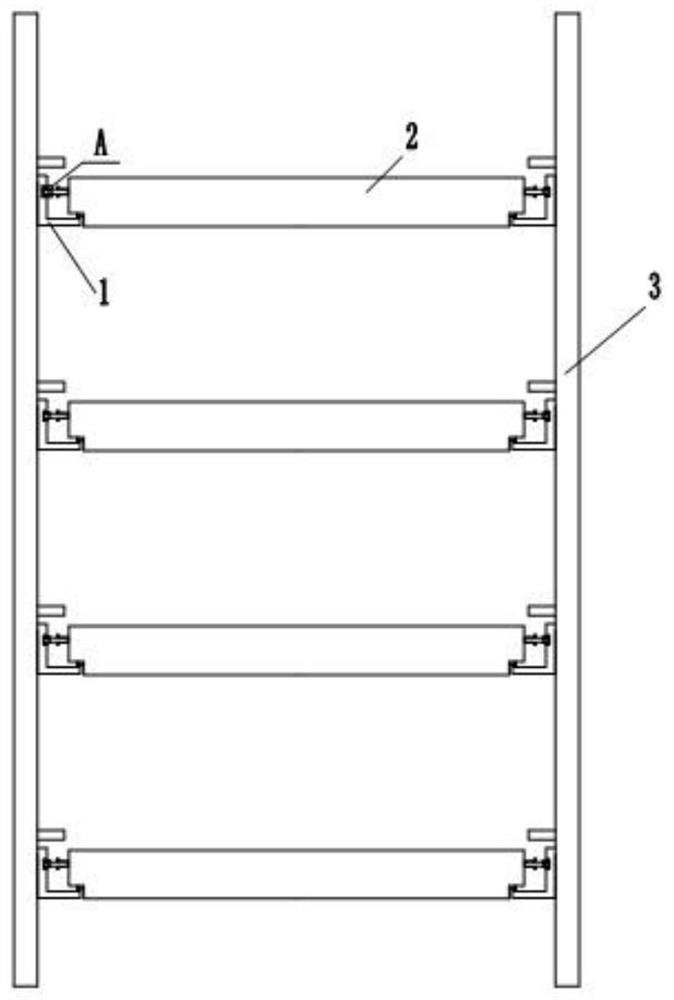

[0028] Such as image 3 , Figure 4 As shown, the difference from Embodiment 1 is that four pairs of parallel guide rails 1 are arranged on the inside of two adjacent rows of columns 3; an electromagnetic relay is arranged between the power supply port connected to the conductive strip 5 and the power supply, and the electromagnetic relay is connected to the remote control receiver. The modules are connected (the electromagnetic relay and the remote control receiving module are not shown in the figure); the conductive brush head assembly is placed in the power supply tank, and the power supply component and the conductive brush head assembly are connected by buckles.

[0029] When the shelf height is too high, use the remote control to control whether the electromagnetic relay is energized or not, so as to control the on-off between the conductive strip and the power supply.

Embodiment 3

[0031]The difference from Embodiment 1 is that the upper and lower ring-shaped slide rails 11 are arranged around the shuttle rack matched with the shuttle car, the ring-shaped slide rail is provided with a lifting frame 12, and the lifting frame 12 is provided with a frame suitable for the ring-shaped slide rail. The pulley of matching is provided with lifting platform 13 on the lifting platform, and the four jiaos of lifting platform are connected with lifting platform by sliding pairs, and the lifting platform is provided with telescopic cargo fork. The lifting frame is also provided with a driving device (not shown in the figure for convenience of illustration), and the driving device forms a transmission connection with the lifting platform, pulleys, and telescopic forks respectively.

[0032] The lifting frame 12 can move on the circular slide rail driven by the driving device. When moving to the front end of the designated shuttle frame, the lifting platform 13 is used i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com