Sparking plug bush with cooling structure

A cooling structure and bushing technology, which is applied in the field of motor nozzle bushings of engines, internal combustion engines, and gas turbines, can solve problems that cannot be solved, and achieve the effects of convenient installation, simple structure, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

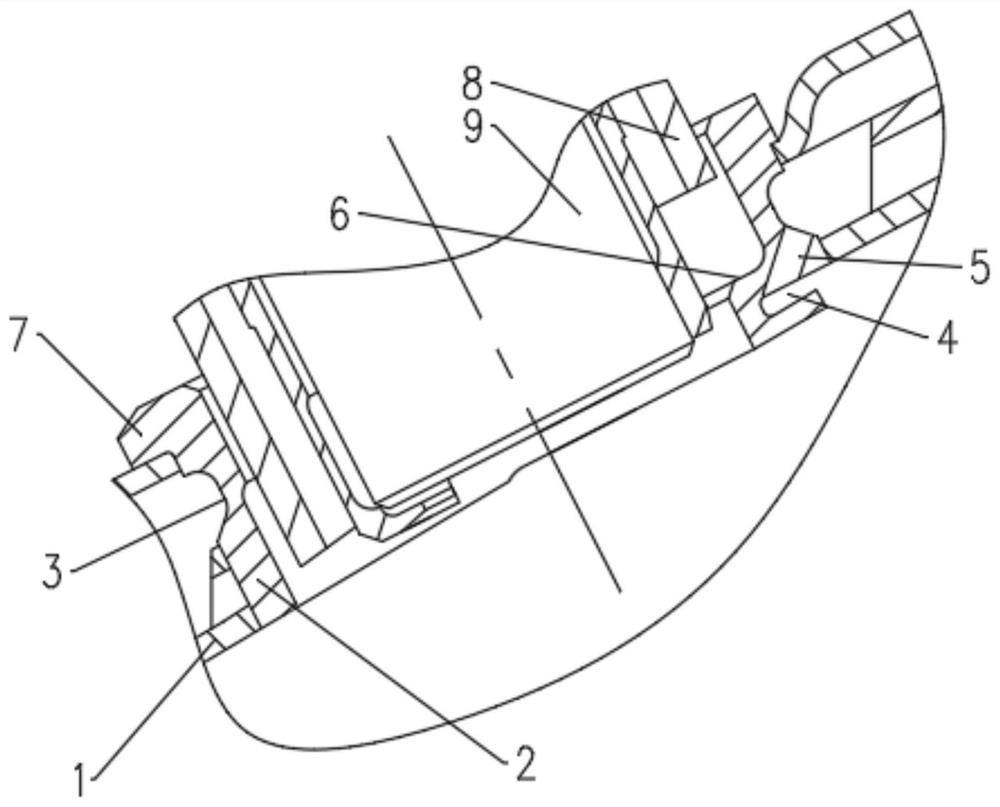

[0020] Such as figure 1 Shown is the structural representation of the present invention:

[0021] The invention provides a nozzle bushing with a cooling structure, which includes a mounting section 2, an air guide groove 3 is provided in the middle of the outer side of the installation section 2, and the air guide groove 3 is ring-shaped, and the outer side of the lower part of the installation section 2 is transversely A cooling gap 4 is opened, and an oblique cooling hole 5 is provided at the lower part of the air guide groove 3 , and the other end of the cooling hole 5 communicates with the inside of the cooling gap 4 .

[0022] When in use, the installation section 2 is welded on the flame tube 1, and there is a gap between the igniter 9 and the nozzle bushing, so the distance between the lower end of the igniter 9 and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com