Non-contact temperature measuring device, temperature measuring module in non-contact temperature measuring device and electronic equipment

A temperature measuring device, non-contact technology, applied in the direction of electric heating devices, electrical components, electric radiation detectors, etc., can solve the problems of large package volume, high price, large heat capacity, etc., achieve small size, low cost, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The technical solutions in the present application embodiment will be described below with reference to the accompanying drawings.

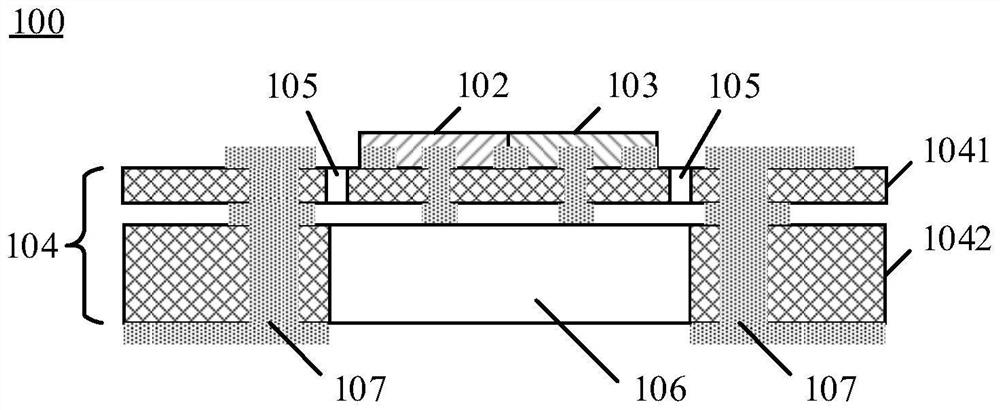

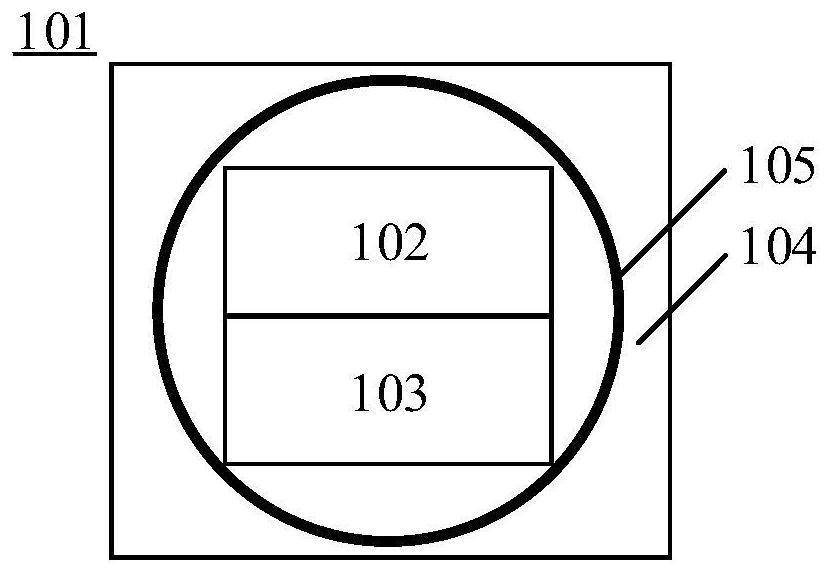

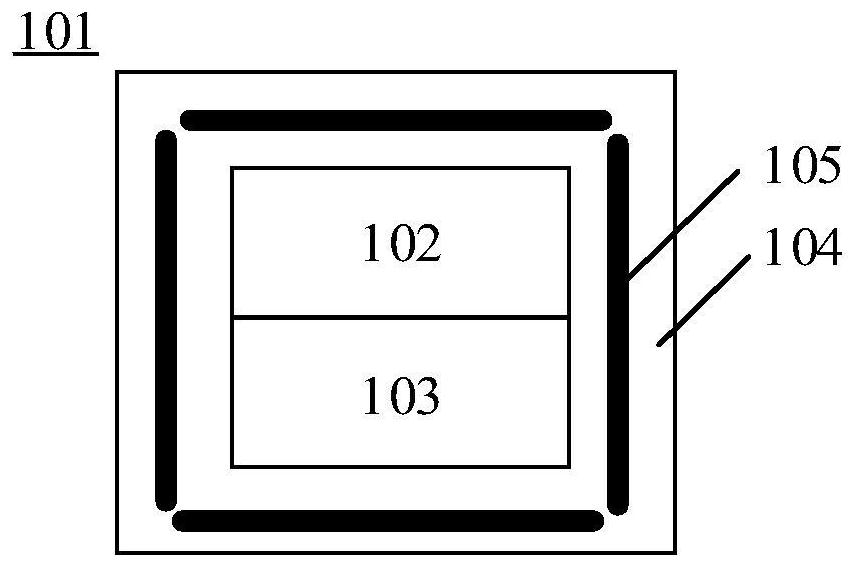

[0060] figure 1 It is a schematic structural diagram of a temperature measurement module 100 in a non-contact temperature measuring device according to the example of the present application, as shown, the temperature sensitive module 100 includes a heating resistor 102, a temperature sensitive resistor 103, and a substrate. 104.

[0061] Wherein, both the heating resistor 102 and the temperature sensitive resistor 103 are provided on the substrate 104, the heating resistor 102 and the temperature sensitive resistance 103 are kept close contact, and the temperature-sensitive resistor 103 can receive the optical signal to be tested, the heating resistor 102 can be The control signal is controlled by heat, and heat the temperature-sensitive resistance is heated by heat transfer to enable the entire temperature measurement module in a constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com