Fuel cell air system decoupling control method and device and storage medium

A fuel cell and air system technology, applied in fuel cells, electrical components, circuits, etc., can solve the problems of slow response speed of air flow and air pressure, complicated process of solving coefficients, and poor practicability, so as to achieve easy production and acquisition and quick response time, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

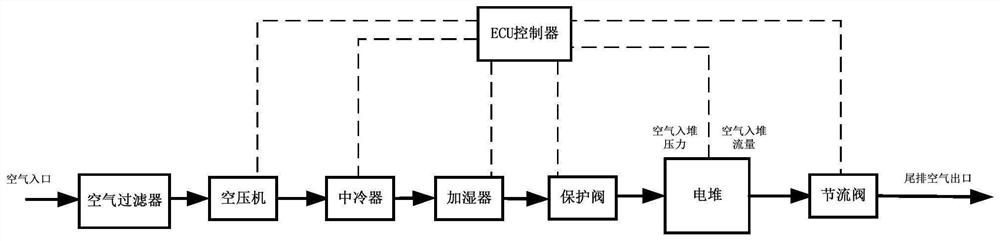

[0042] A schematic diagram of the fuel cell air system is shown in figure 1 , including air filters, air compressors, intercoolers, humidifiers, protection valves, pressure sensors and flowmeters installed at the stack inlet ( figure 1 Not shown in the picture), throttle valve and ECU controller, etc.; for the actual stack, the air needs to go through a series of processes of filtration, pressurization, cooling, and humidification to ensure the high-efficiency chemical reaction of the stack;

[0043] The air filter is installed at the front end, and its function is to filter impurities and harmful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com