CNC device

A technology of numerical control device and control unit, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of deterioration of machining accuracy, etc., and achieve the effect of mechanical vibration suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

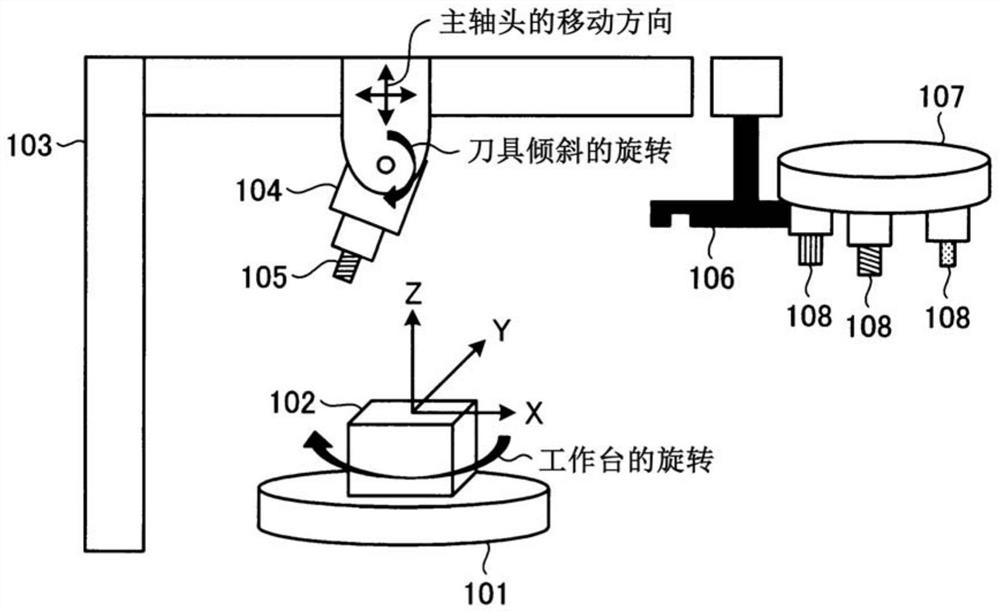

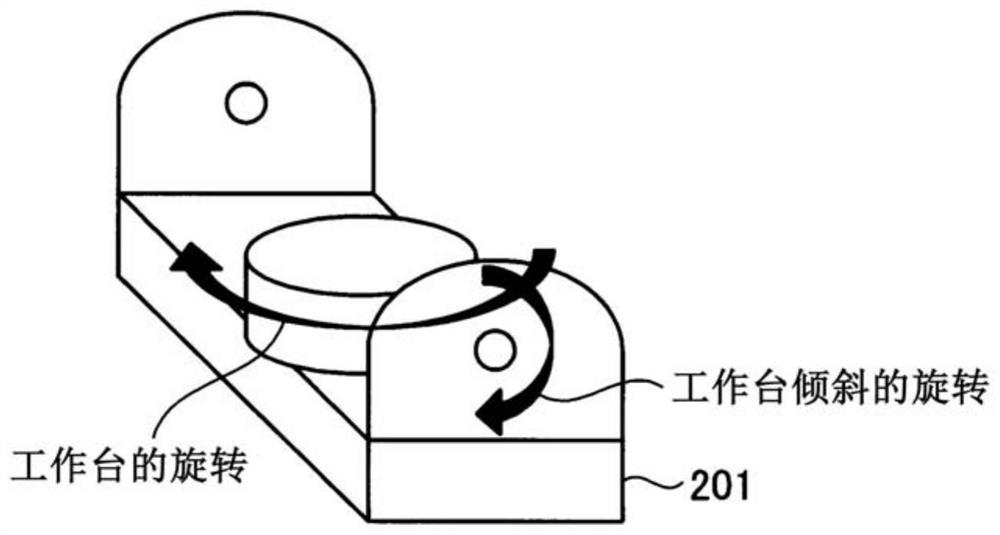

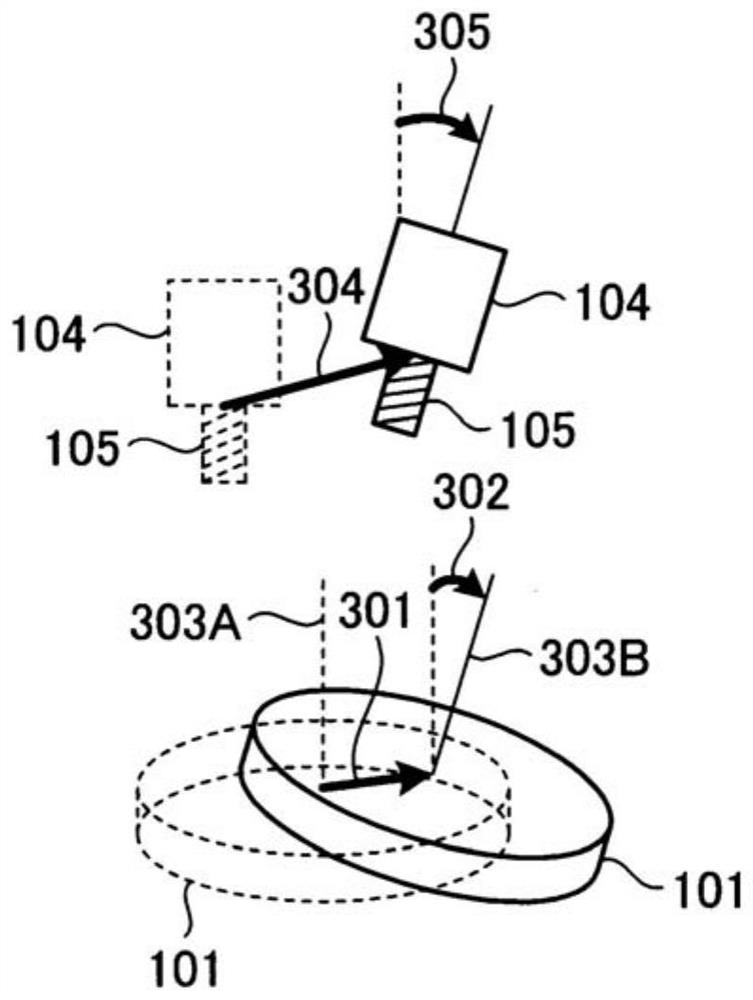

[0024] First, regarding the machine tool to be controlled by the numerical control device according to the present invention, use Figure 1 to Figure 3 Be explained. figure 1 This is a diagram showing a configuration example of a machine tool controlled by a numerical control device.

[0025] figure 1 The work machine shown has a table 101 . The workpiece 102 , which is an object to be processed, is fixed on the table 101 . The table 101 has a rotation axis parallel to the Z axis. In addition, the machine tool has a column 103 . A spindle head 104 is attached to the column 103 , and a tool 105 is attached to the spindle head 104 . In addition, the spindle head 104 has a mechanism for tilting the tool 105 . The numerical control device (not shown) controls the relative position and angle of the tool 105 fixed to the spindle head 104 with respect to the three-dimensional space of the workpiece 102 to make the tool 105 come into contact with the workpiece 102 . In this sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com