Multi-mass specific gravity sorting machine

A sorting machine and specific gravity technology, applied in the field of sorting machines, can solve the problems of reducing the service life of the sieve plate, reducing the sorting efficiency, and delaying the falling time of fine particles, so as to avoid the accumulation of materials, improve the sorting efficiency, The effect of increasing the drop area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

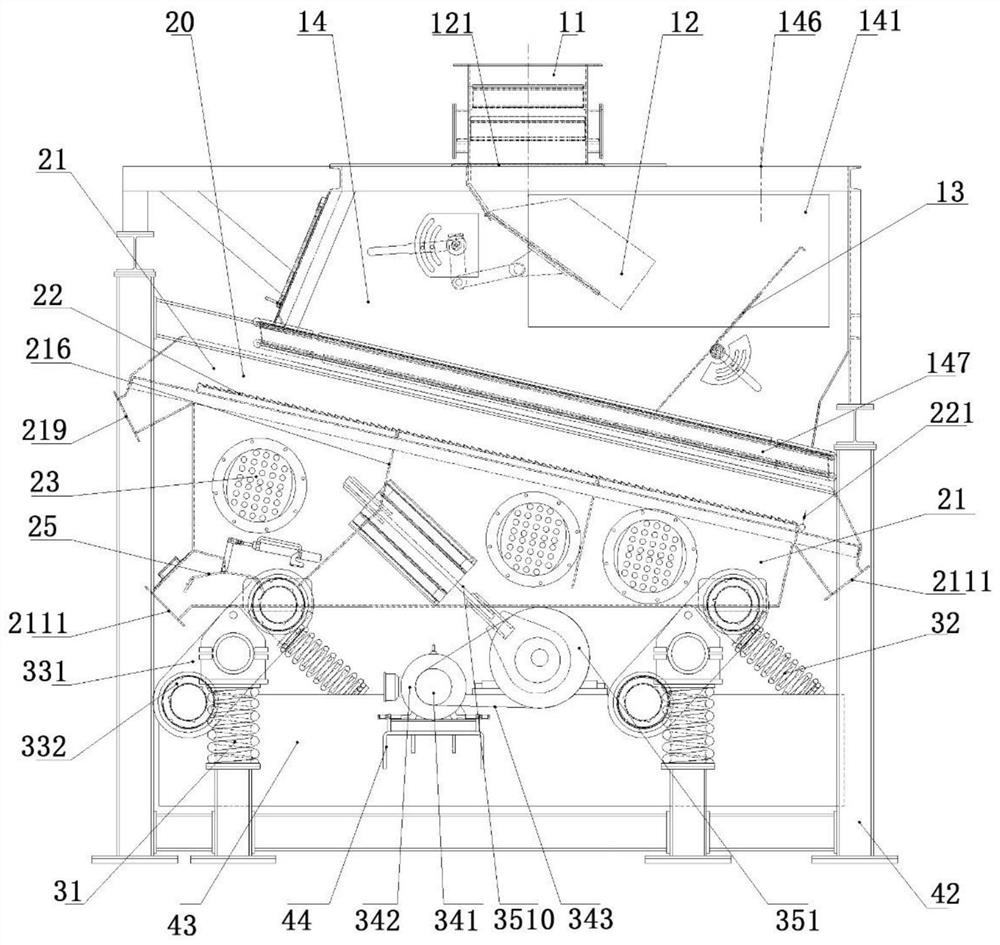

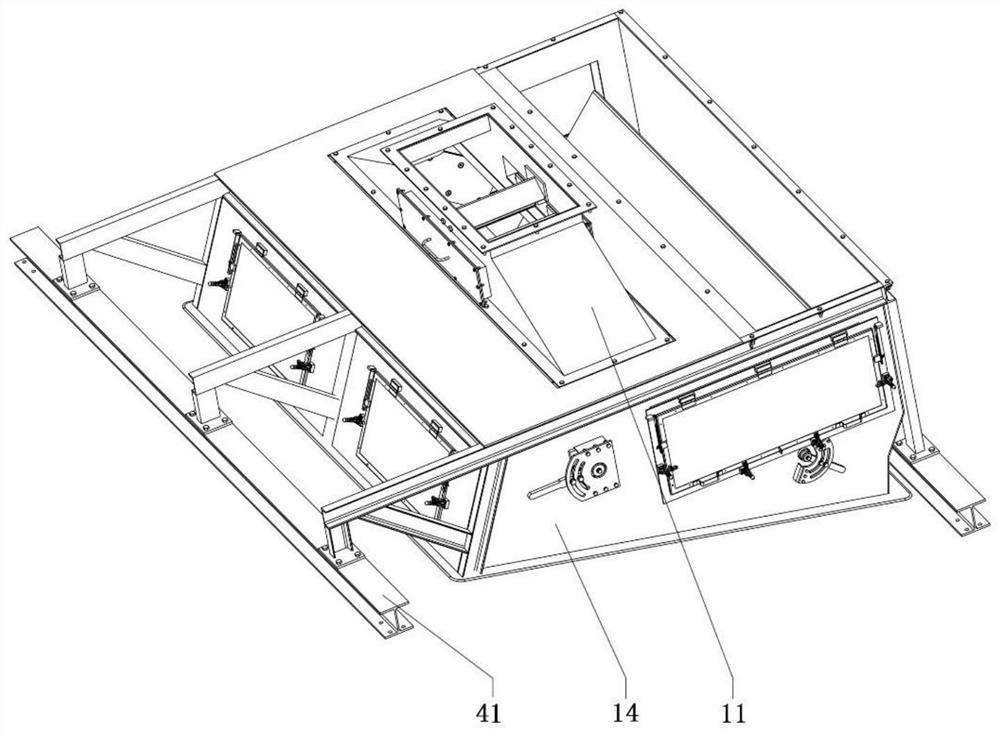

[0048] refer to Figure 1 to Figure 25 As shown, a multi-mass specific gravity separator includes a feed module 10, a sorting module 20 and a vibration drive module 30. The improvement is that the feed module 10 includes a feed box 14, and the feed module 10 includes a feed box 14. The upper part of the feed box 14 is provided with a material distribution chute 11, and the inside of the material distribution chute 11 is provided with at least two layers of material distribution plates. The material is dispersed; the inside of the feed box 14 is provided with a blanking chute 12, and the blanking chute 12 is located below the distribution chute 11, and the blanking chute 12 is provided with a first angle adjustment mechanism and passed The first angle adjustment mechanism adjusts the angle of inclination to adjust the blanking position of the material; the inside of the feed box 14 is provided with a draft baffle 13, and the draft baffle 13 is connected to the blanking chute 12...

Embodiment 2

[0082] On the basis of embodiment 1, with reference to Figure 5 As shown, the distribution chute 11 includes a distribution chute body 111, the upper end of the distribution chute body 111 is connected to the material conveying belt, and the lower end is connected to the feed box 14; the width of the upper end of the distribution chute body 111 is To match the width of the material conveying belt, the width of the lower end of the distribution chute body 111 is greater than the width of the upper end.

[0083] In this embodiment, the material distribution chute body 111 is a trapezoidal funnel with openings both up and down, its upper end is connected to the material conveying belt through a flange, and its lower end is connected to the feed box 14 . The material enters the material distribution chute 11 through the material conveying belt and is divided by the material distribution plate. In this embodiment, since the width of the upper end of the material distribution chut...

Embodiment 3

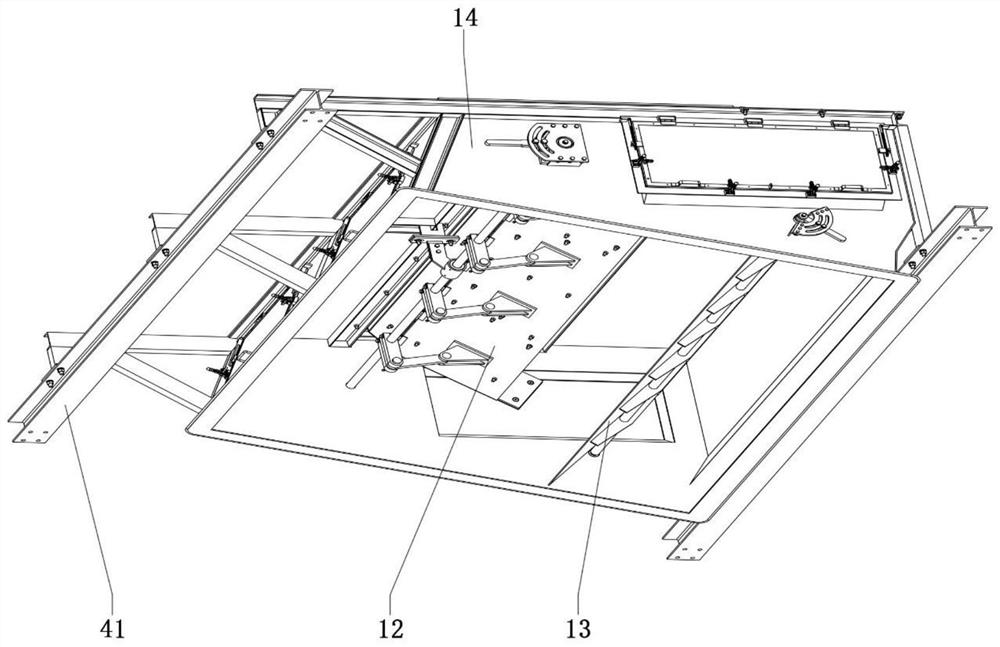

[0104] On the basis of embodiment 1 or 2, with reference to Figure 6 to Figure 9 As shown, the blanking chute 12 includes a blanking chute body 129, the blanking chute body 129 is rotatably connected to the flange 121 through a hinge 127, and the flange 121 is fixedly mounted on the feed box 14, so The flange 121 matches the shape of the lower end of the distribution chute 11 .

[0105] In this embodiment, the flange 121 is used to install the blanking chute body 129 and provides support and a rotation center for the rotation of the blanking chute body 129 through the hinge 127 . By setting the flange 121, on the one hand, the installation of the blanking chute body 129 can be facilitated, and at the same time, a pivot point can be provided for the angle adjustment of the blanking chute body 129; It can also gather the materials, so that the materials can be conveniently entered into the blanking chute body 129 through the flange 121 .

[0106] Further, the first angle adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com