A graphite-coated carbonization equipment for lithium battery electrode production

A graphite-coated, lithium battery technology, applied in battery electrodes, graphite, carbon preparation/purification, etc., can solve the problems of poor carbonization effect, uneven stirring, and high production costs, and achieve easy control, speed up the reaction, and facilitate the The effect of heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

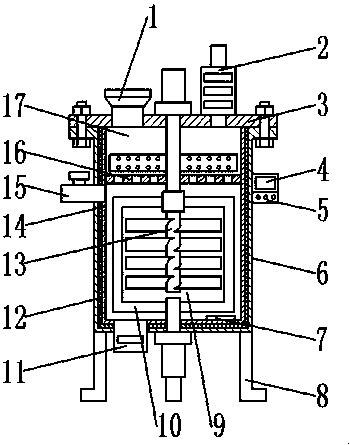

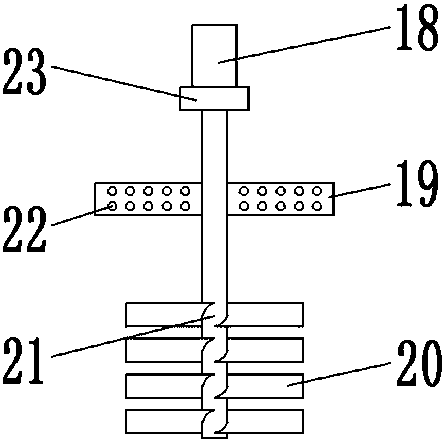

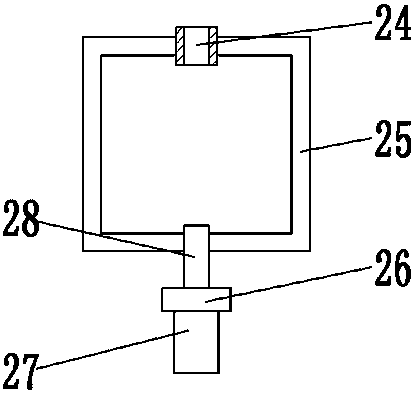

[0020] see Figure 1-4 , a graphite-coated carbonization equipment for the production of lithium battery electrodes, comprising a tank body and an upper cover 3; the tank body is set as a hollow cylinder, and is composed of an insulating layer 6, a heating resistance wire 12 and a heat-conducting layer 14; The heating resistance wire 12 is arranged between the insulation layer 6 and the heat conducting layer 14, and the heating resistance wire 12 is connected with the control switch 5 through a wire; the top opening of the tank body is provided with an upper cover 3; the upper cover 3 is connected by bolts and nuts They are screwed together and fixedly connected to the tank body, and the upper cover 3 is provided with a feed pipe 1 and an exhaust gas filter device 2; the feed pipe 1 is arranged on the left side of the upper cover 3, and the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com