Novel intelligent detection and classification chain conveyor system

A chain conveyor and intelligent detection technology, which is applied in the field of aluminum electrolysis, can solve problems such as dust pollution in the working environment, low production efficiency, and large production safety hazards, and achieve the effects of reducing human participation, improving production efficiency, and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

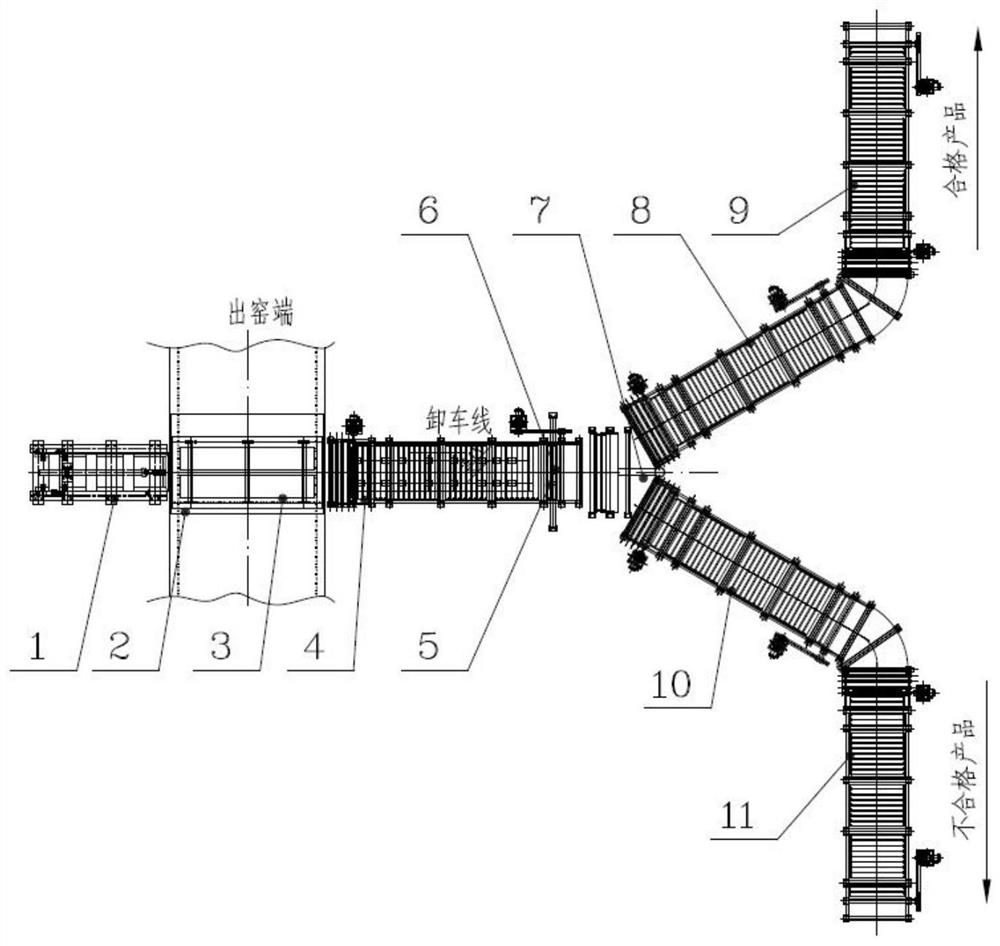

[0014] Such as figure 1 Shown, the present invention is implemented like this: the finished carbon block in the carbon block trolley 3 on the traverse car 2 is pushed on the chain conveyor-4 by the pusher 1, and the chain conveyor-4 is with the carbon block When passing under the radio frequency identification system 5 and the carbon block appearance detection system 6, the radio frequency identification system 5 works, reads the bar code of the carbon block, and identifies the entire production process information of the carbon block, and at the same time the carbon block appearance detection system 6 works to comprehensively detect the carbon block. Whether the block appearance is defective (such as cracks, etc.), the system can only judge whether the carbon block is a quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com