Coral sand-doped AC-13 normal-temperature asphalt mixture and preparation method thereof

A technology of normal temperature asphalt and mixture, applied in the field of asphalt pavement materials, can solve problems such as high strength, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

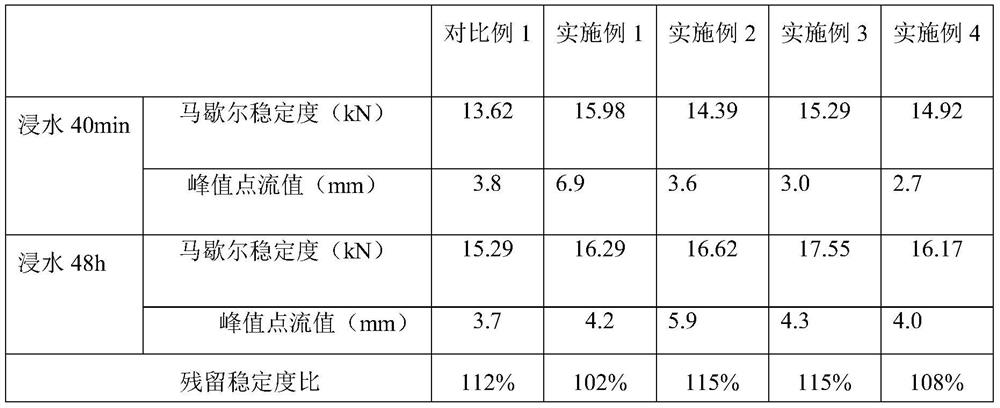

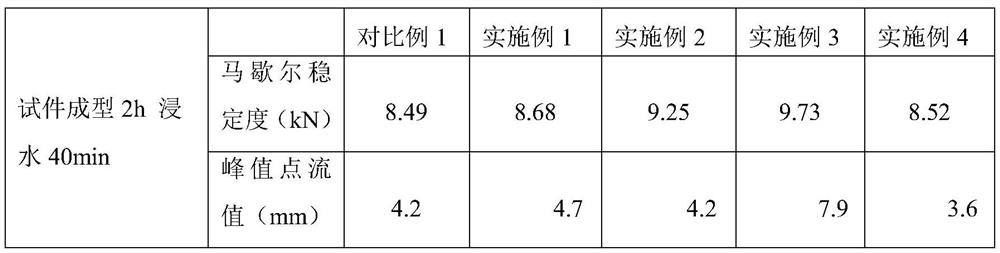

Examples

preparation example Construction

[0052] As mentioned above, the second aspect of the present invention provides a kind of preparation method of aforementioned mixture, it is characterized in that, this method comprises:

[0053] (1) heating 66 parts by weight of reactive type normal temperature liquid pitch to 70-100°C;

[0054] (2) The reaction type normal temperature liquid asphalt obtained in step (1) is mixed with the coral sand of 22-98 parts by weight, the coarse aggregate of 820-860 parts by weight and the fine aggregate of 330-400 parts by weight in a mixing pot The first mixing obtains the mixture A;

[0055] (3) The mixture A obtained in step (2) is mixed with the curing agent of 10-15 parts by weight and the ore powder of 55-65 parts by weight in a mixing pot to obtain the normal temperature asphalt mixture;

[0056] The conditions for the first mixing include: the temperature is 15-100°C, the stirring speed is 30-40rpm, and the time is 1-3min;

[0057] The conditions for the second mixing includ...

Embodiment 1

[0067] (1) According to the formula of 20 parts by weight of ricinoleic acid, 8 parts by weight of sodium laurylalanine, 4 parts by weight of low-molecular polyamide, and 25 parts by weight of calcium lignosulfonate, each raw material is weighed and mixed to obtain a reactive type solvent;

[0068] According to the formula of 45 parts by weight of 70# base asphalt, 25 parts by weight of water-based epoxy resin, 40 parts by weight of reactive solvent and 30 parts by weight of n-dodecyl triethoxysilane, the raw materials were weighed and mixed to obtain reactive normal temperature liquid pitch ;

[0069] (2) Take 66 parts by weight of the reaction-type room temperature liquid pitch prepared in step (1), and heat it to 80° C.;

[0070] (3) Add respectively 7.8 parts by weight of coarse coral sand, 15.9 parts by weight of fine coral sand, 850.2 parts by weight of coarse limestone and 392.1 parts by weight of fine limestone in the mixing pot of the reaction type normal temperature...

Embodiment 2

[0074] (1) According to the formula of 20 parts by weight of ricinoleic acid, 8 parts by weight of sodium laurylalanine, 4 parts by weight of low-molecular polyamide, and 25 parts by weight of calcium lignosulfonate, each raw material is weighed and mixed to obtain a reactive type solvent;

[0075] According to the formula of 45 parts by weight of 70# base asphalt, 25 parts by weight of water-based epoxy resin, 40 parts by weight of reactive solvent and 30 parts by weight of n-dodecyl triethoxysilane, the raw materials were weighed and mixed to obtain reactive normal temperature liquid pitch ;

[0076] (2) Take 66 parts by weight of the reaction-type room temperature liquid pitch prepared in step (1), and heat it to 80° C.;

[0077] (3) Add respectively 15.6 parts by weight of coarse coral sand, 31.8 parts by weight of fine coral sand, 842.4 parts by weight of coarse limestone and 376.2 parts by weight of fine limestone in the mixing pot of the reaction type normal temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com