Underwater equipment operation monitoring system and method

A technology for underwater equipment and operation monitoring, applied in the direction of measuring devices, instruments, thermometers, etc., can solve the problems of fixed detection frequency, large influence of artificial level, difficult detection and detection of underwater equipment failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

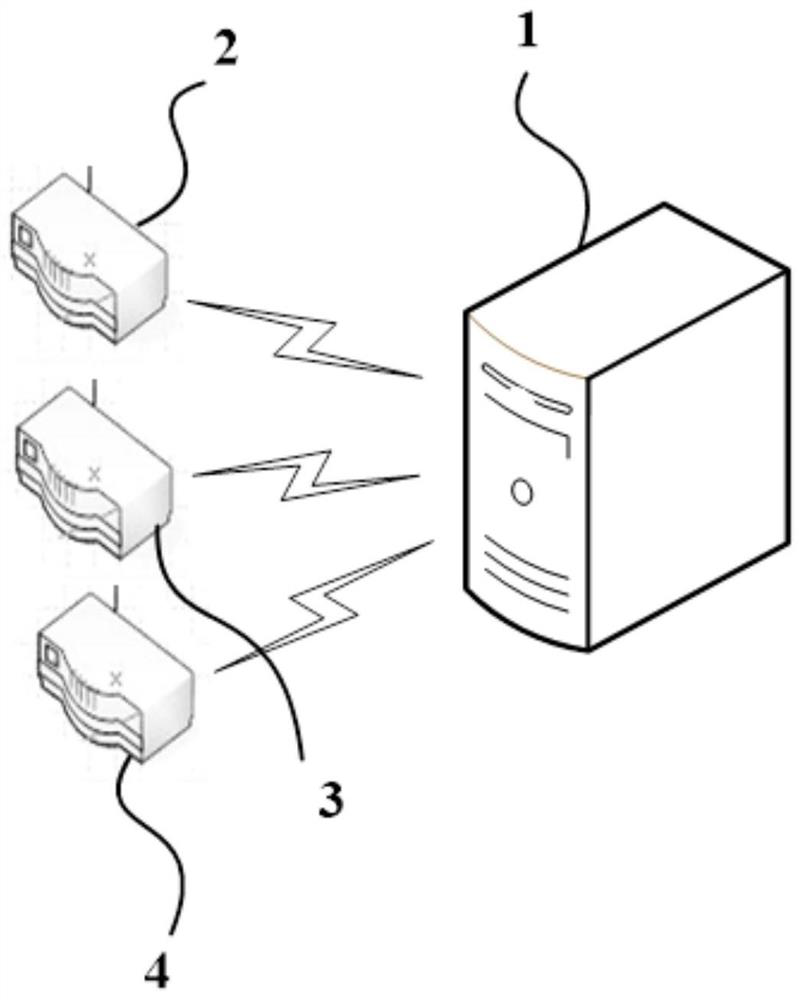

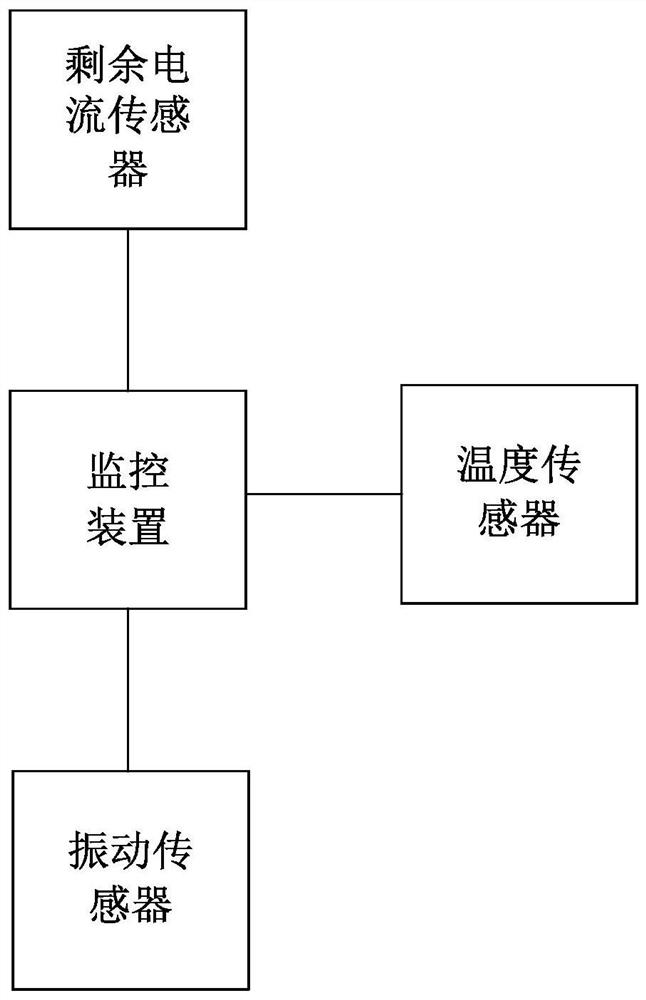

[0046] Such as Figure 1-2 As shown, a residual current monitoring system for underwater equipment includes an operation box installed on site, and the underwater equipment is connected to the switchgear installed in the operation box through a power cable, and also includes a monitoring device 1, a residual current Sensor 2, vibration sensor 3 and temperature sensor 4;

[0047]The residual current sensor 2 and the temperature sensor 4 are arranged on the power cable, the vibration sensor 3 is arranged on the underwater equipment, the residual current sensor 2, the vibration sensor 3 and the The temperature sensors 4 are respectively connected in communication with the monitoring device 1, and the monitoring device 1 is connected in communication with the switching device;

[0048] The residual current sensor 2 is used to detect the residual current of the three-phase line in the power cable in real time, obtain a residual current signal, and send the residual current signal ...

Embodiment 2

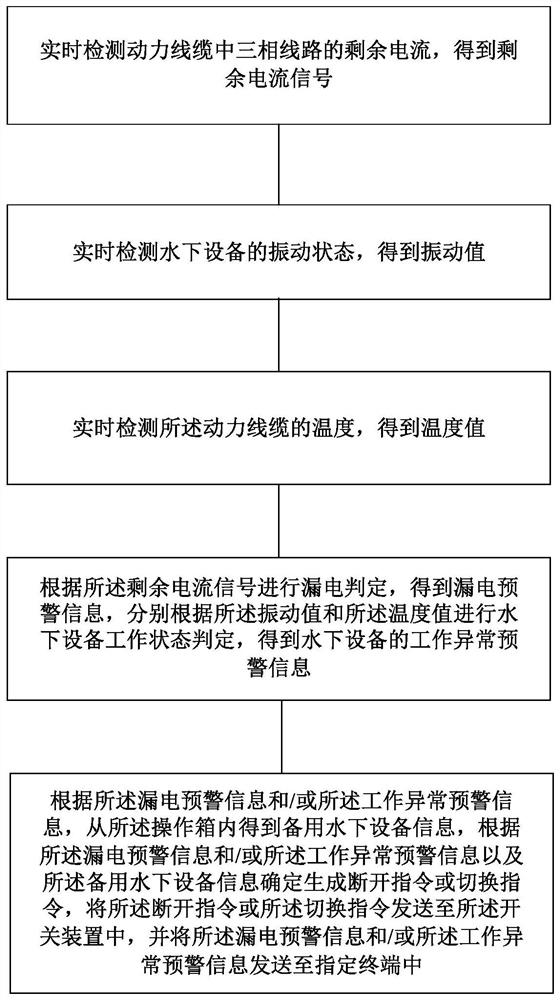

[0092] Such as image 3 As shown, a residual current monitoring method for underwater equipment, the underwater equipment is connected to the switch device in the operation box set on the site through a power cable, including the following steps:

[0093] Real-time detection of the residual current of the three-phase line in the power cable to obtain the residual current signal;

[0094] Real-time detection of the vibration state of underwater equipment to obtain the vibration value;

[0095] Detecting the temperature of the power cable in real time to obtain a temperature value;

[0096] Leakage judgment is performed according to the residual current signal, and leakage warning information and a disconnection instruction are obtained, and the leakage warning information is sent to a designated terminal, and the disconnection instruction is sent to the switch device for the switch device to Underwater equipment is closed and controlled;

[0097] Judging the working state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com