Frictional wear experimental device capable of realizing time-varying positive pressure

A technology of friction and wear and experimental equipment, which is applied in the direction of measuring equipment, testing wear resistance, instruments, etc., can solve the problems of deviation in actual conditions, difficulty in accurately describing the evolution of friction interface, etc., and achieve simple installation, simple structure, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

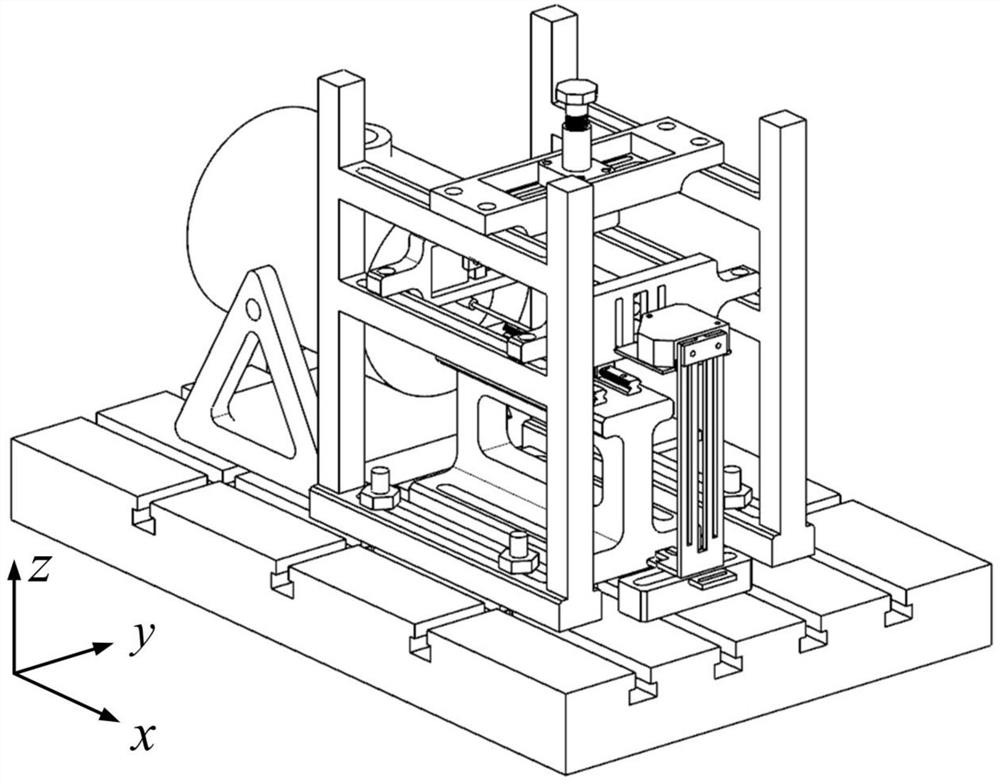

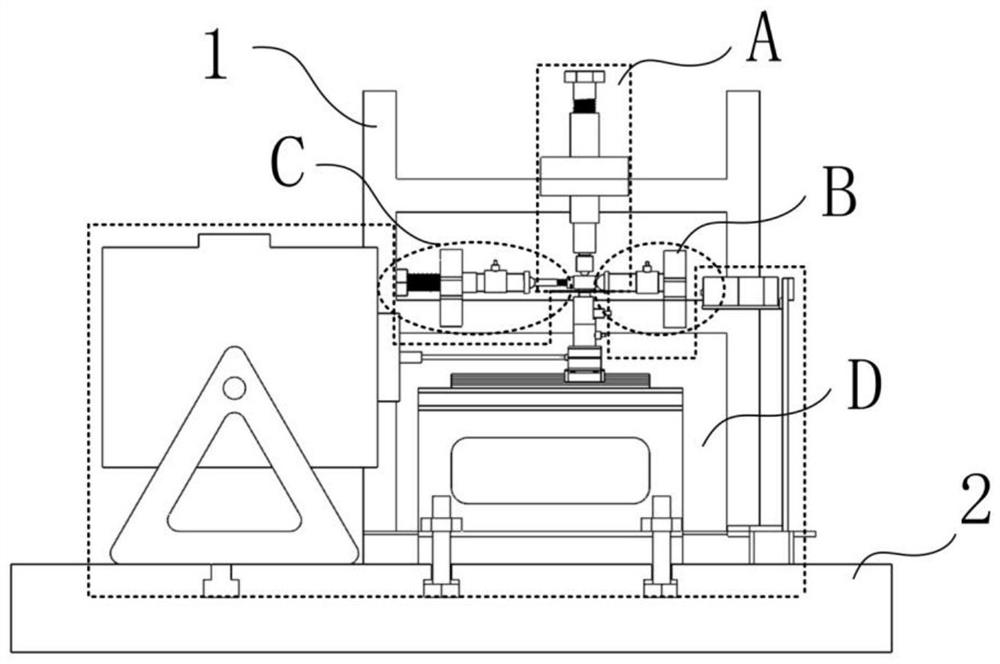

[0035] Such as figure 1 and figure 2 As shown, the experimental device of the present invention generally includes a support frame (1), a static specimen module (A), a left support module (B), a right support module (C) and a dynamic specimen module (D).

[0036] The support frame (1) is a frame structure designed with upper, middle and lower beams, and each beam is provided with a moving groove with a width of 16mm; the lower end beam of the support frame (1) is connected to the workbench ( 2) Fixed connection.

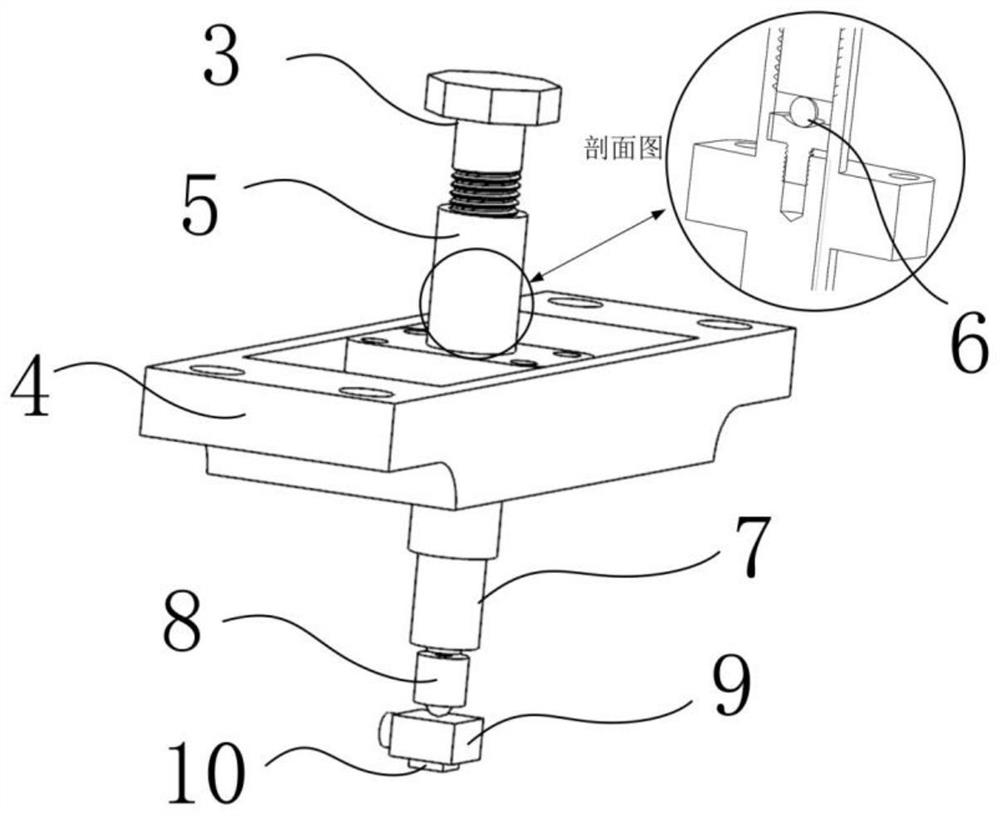

[0037] Such as image 3 As shown, the static test piece module (A) includes an adjusting bolt (3), a transverse mounting frame (4), an upper sleeve (5), an upper adapter (6), a piezoelectric actuator (7), a lower Adapter (8), static piece set (9) and static test piece (10). Wherein the adjusting bolt (3) is an M20 bolt, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com