Method for evaluating residual life of high-temperature alloy blade

A technology for superalloy and life assessment, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of life prediction accuracy deviation, calculation result deviation, weak internal correlation, etc., and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

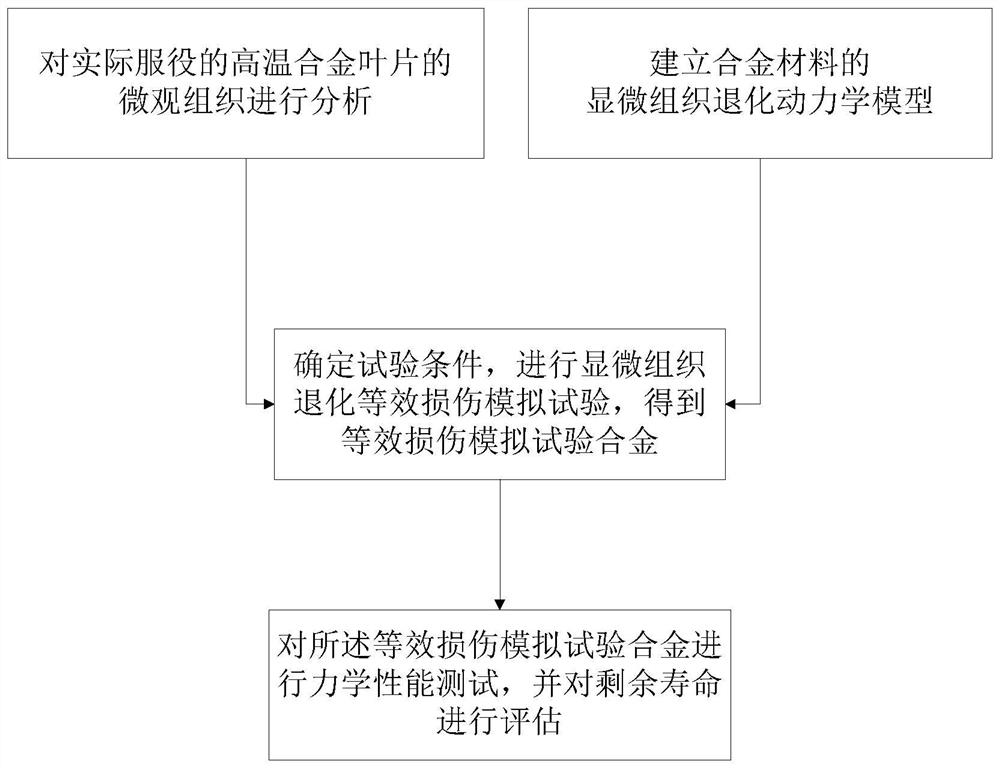

[0075] (1) damage analysis steps:

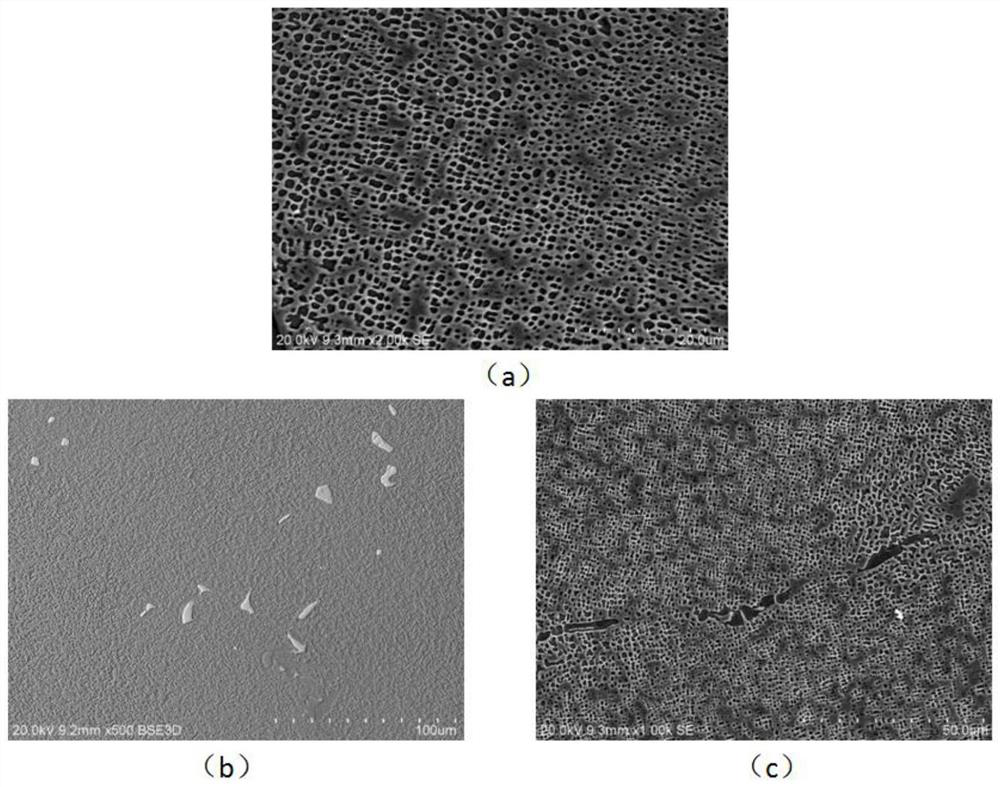

[0076] F Class turbine stage of a gas turbine moving blade 1, when the total length of 28,000 hours in service, the location service blade tip attachment such as tissue damage figure 2 FIG: matrix alloy blade tip position of gamma] 'of spherical coarse tissue, did not show significant raft phenomenon, wherein gamma] between the dendrite dendrite' significantly different relative size, dendrite gamma] 'phase average size (equivalent diameter) of about 0.83μm, the interdendritic γ 'phase average size (equivalent diameter) of about 1.15μm. Matrix alloy blade tip position of MC carbides no obvious degradation decomposition phenomena, dispersed grain boundaries have M 23 C 6 Coarse carbide particles.

[0077] (2) Modeling steps:

[0078] The establishment of microstructure degradation in service during the dynamic model, as follows:

[0079] Gas Turbine blade alloys carry in service near equivalent material damage simulation test, comprising a static...

Embodiment 2

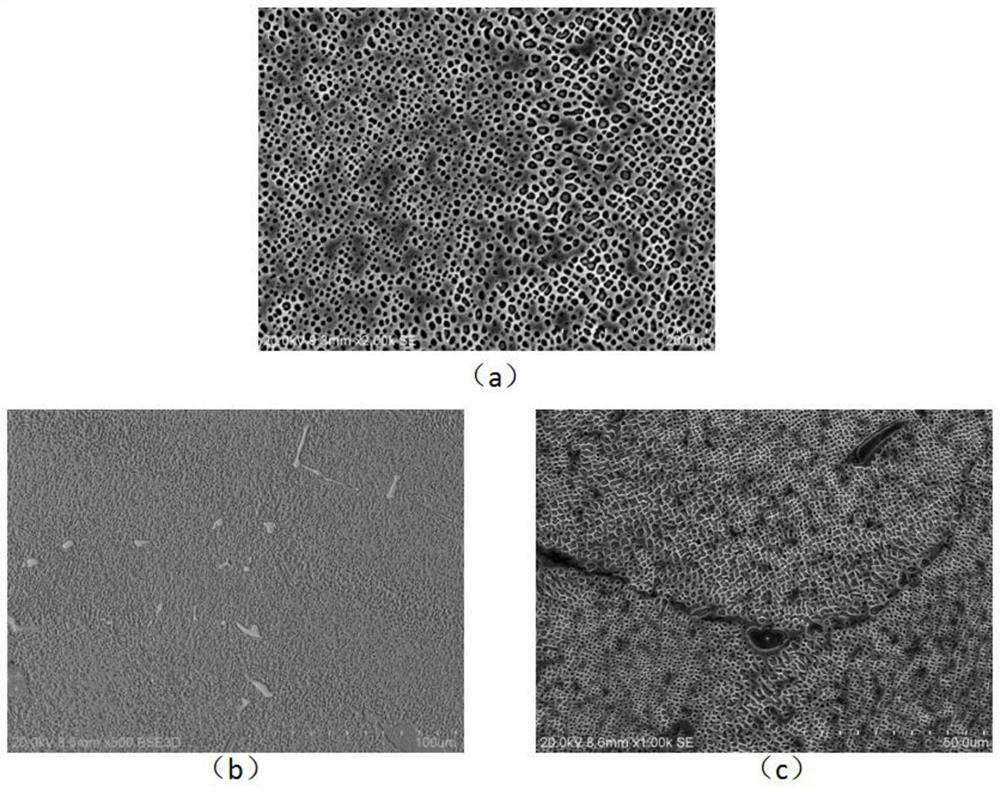

[0098] The remaining life evaluation method of a gas turbine high temperature alloy blade is analyzed in accordance with the life evaluation method disclosed in the present invention, and the microstructure of the high-temperature alloy blade of the actual service is analyzed, and the distribution of microstructured degradation damage is established, and the development process is established. Microstructure degradation kinetics, identified test conditions, obtained an equivalent damage simulation test alloy of 900 ° C / 10000H, established a different stress level under 900 ° C, different remaining lasting Larson-Miller curves (if attached Figure 4 As shown, accordingly, the corresponding relationship between the remaining life of acceleration and long-lasting test is to extrapolate the remaining service life of the actual combustion engine blade.

Embodiment 3

[0100] The remaining life evaluation method of a gas turbine high temperature alloy blade is analyzed in accordance with the life evaluation method disclosed in the present invention, and the microstructure of the high-temperature alloy blade of the actual service is analyzed, and the distribution of microstructured degradation damage is established, and the development process is established. Microstructure degradation kinetics, identified test conditions, obtained near-service equivalent damage simulation test alloys, to conduct a long-term persistent creep performance test test under near service conditions at 900 ° C / 90MPa, the remaining persistence of the alloy is 12631 Hours, therefore, the remaining life of the orientation combustion engine blade under 900 ° C / 90 mPa was inferred in the long-time delivery of 25,000 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com