Air-cooled heat exchange type double-effect heat dissipation type motor

A heat-exchange and heat-dissipating technology, applied in the field of electric motors, can solve problems such as overheating, burnout of the motor, and insufficient heat-dissipating scales, and achieve the effect of improving air flow, improving heat-dissipating efficiency, and achieving double cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

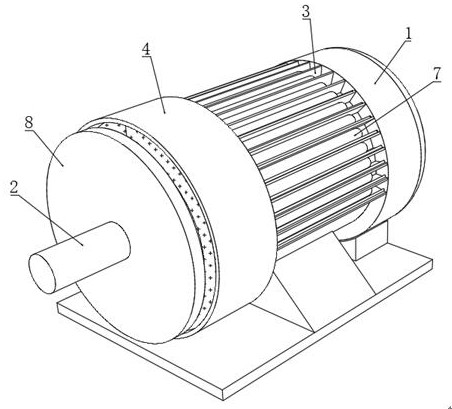

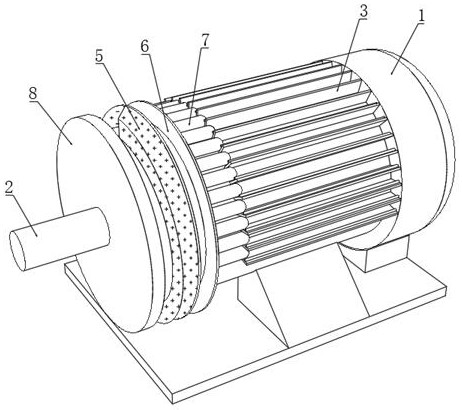

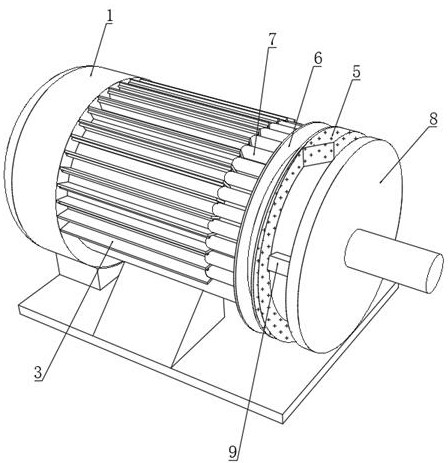

[0047] see figure 1 and figure 2 , an air-cooled heat exchange type double-effect heat dissipation motor, comprising a motor body 1 and a rotating shaft 2, the rotating shaft 2 is rotatably connected to the front end of the motor body 1, and the outer end of the motor body 1 is fixedly connected with a plurality of evenly distributed heat dissipation scales 3 , the outer side of the motor body 1 is covered with an outer thin tube 4, the outer thin tube 4 is located between the rotating shaft 2 and the heat dissipation scales 3, a curved surface ring plate 5 is slidingly connected between the outer thin tube 4 and the motor body 1, the outer thin tube 4 and the The fixed ring piece 6 is fixedly connected between the motor body 1, the curved surface ring plate 5 is located between the rotating shaft 2 and the fixed ring piece 6, the space between the curved surface ring plate 5 and the fixed ring piece 6 is filled with cooling water, and the gap between the adjacent cooling sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com