Capacitor-embedded printed circuit board

A printed circuit board and circuit board technology, which is applied in the directions of printed circuit components, circuit thermal devices, electrical components, etc., can solve the problems such as the lack of attention, improvement, and high-frequency performance influence on the temperature of the circuit board, so as to improve the performance of normal use. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

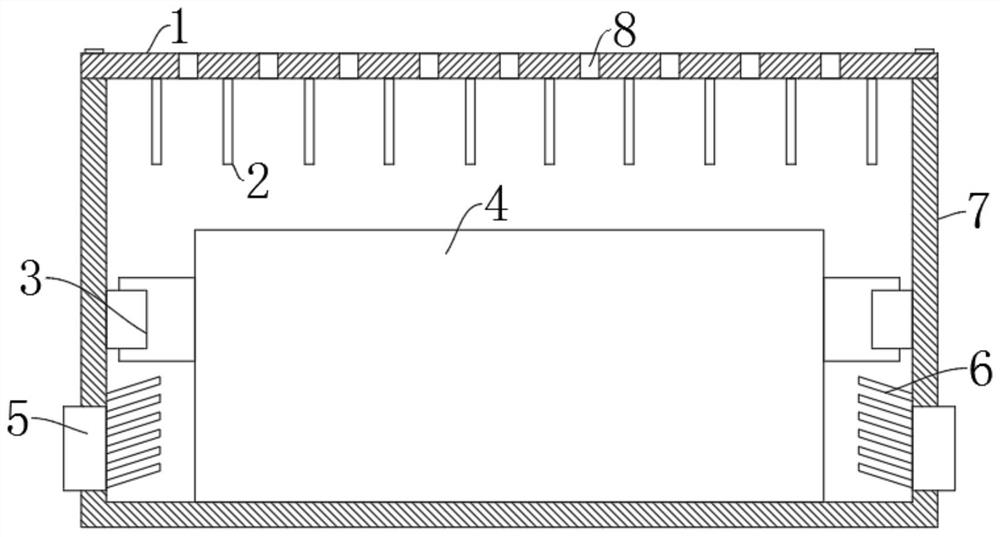

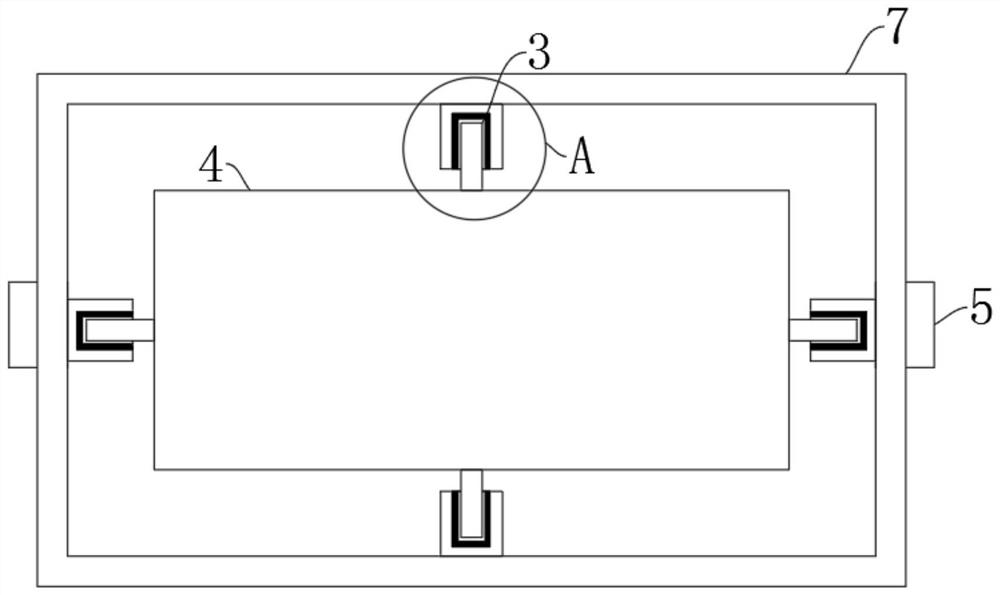

[0017] refer to figure 1 , an embedded printed circuit board, including a circuit board body 4 and a protective shell 7, the protective shell 7 can protect the circuit board body 4, and prevent the circuit board body 4 from being affected by an external force, the circuit board The main body 4 is located inside the protective shell 7, the circuit board main body 4 and the fan 5 are connected to the power supply device through wires, and an external control switch is installed on the wires.

[0018] The inner both sides lower ends of the protective shell 7 are equipped with a blower fan 5 that runs through the protective shell 7. The air outlet of the blower fan 5 is positioned at the inner side of the protective shell 7. The air outlet of the blower fan 5 is fixedly equipped with a plurality of inclined plates 6. The inclined plates 6 can Ensure that the wind blown by the fan 5 is inclined upward, and the heat generated by the circuit board body 4 is driven to the upper end of...

Embodiment 2

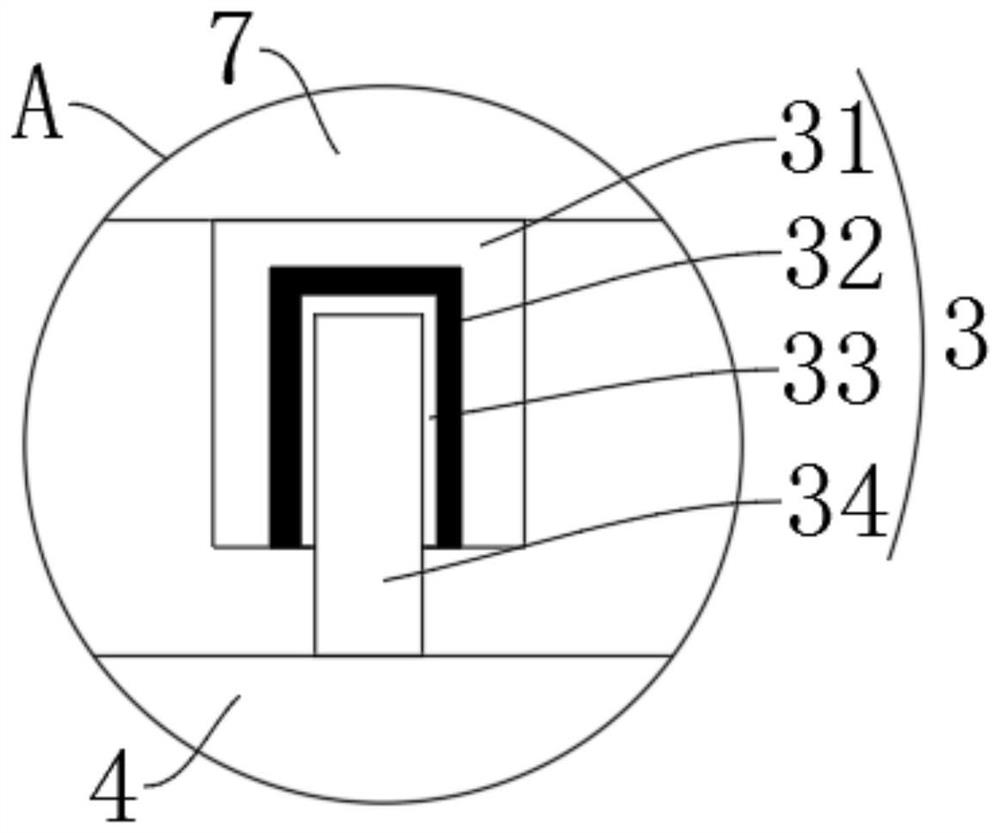

[0020] refer to Figure 1-3 The difference between this embodiment and Embodiment 1 is that multiple groups of connection structures 3 are evenly installed between the circuit board body 4 and the inner middle part of the protective shell 7, and the connection structures 3 include a fixing seat 31, a rubber pad 32, and a square groove 33 And the straight plate 34, the fixed seat 31 is installed on the inner side of the protective shell 7, the straight plate 34 is horizontally installed on one side of the circuit board body 4, the square groove 33 is vertically opened on one side of the fixed seat 31, and the straight plate 34 is inserted in the square The inner side of the groove 33, and the size of the square groove 33 matches the size of the straight plate 34, and the mutual cooperation between the straight plate 34 and the square groove 33 effectively realizes the fixing of the position of the circuit board body 4, and can be installed more quickly. Prevent the circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com