Anti-radiation reinforced SOI device based on neutron irradiation and preparation method thereof

An anti-radiation hardening and device technology, which is used in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor/solid-state device components, etc. It can restore the carrier lifetime and mobility, avoid interface incompatibility, and save process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

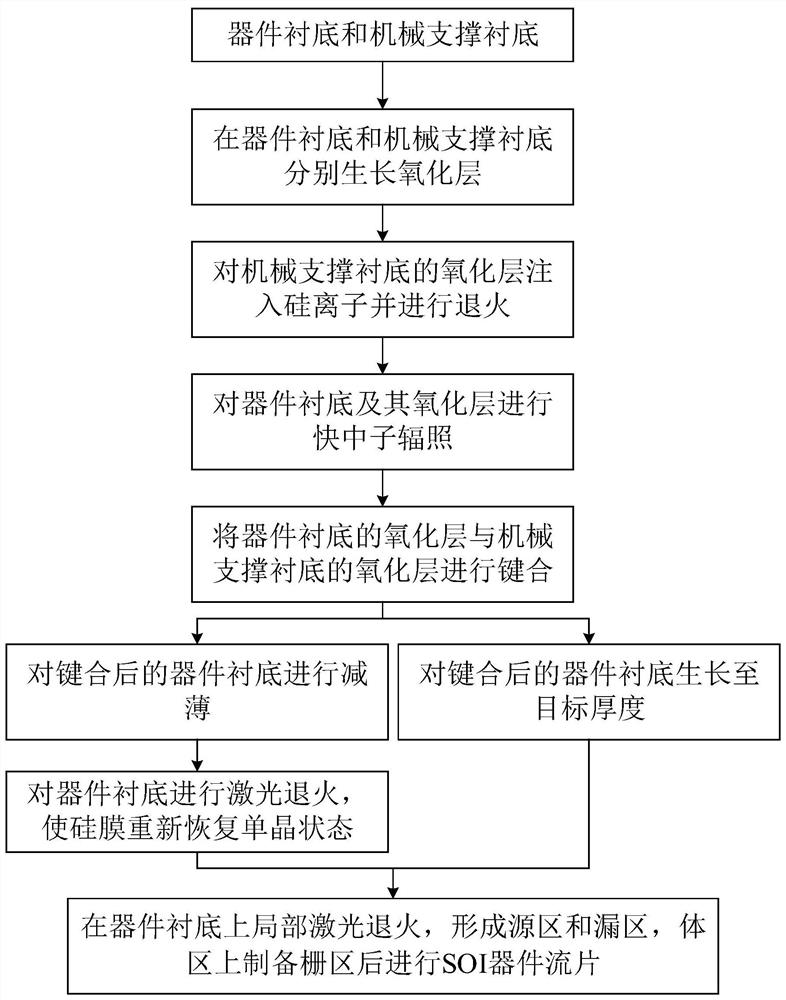

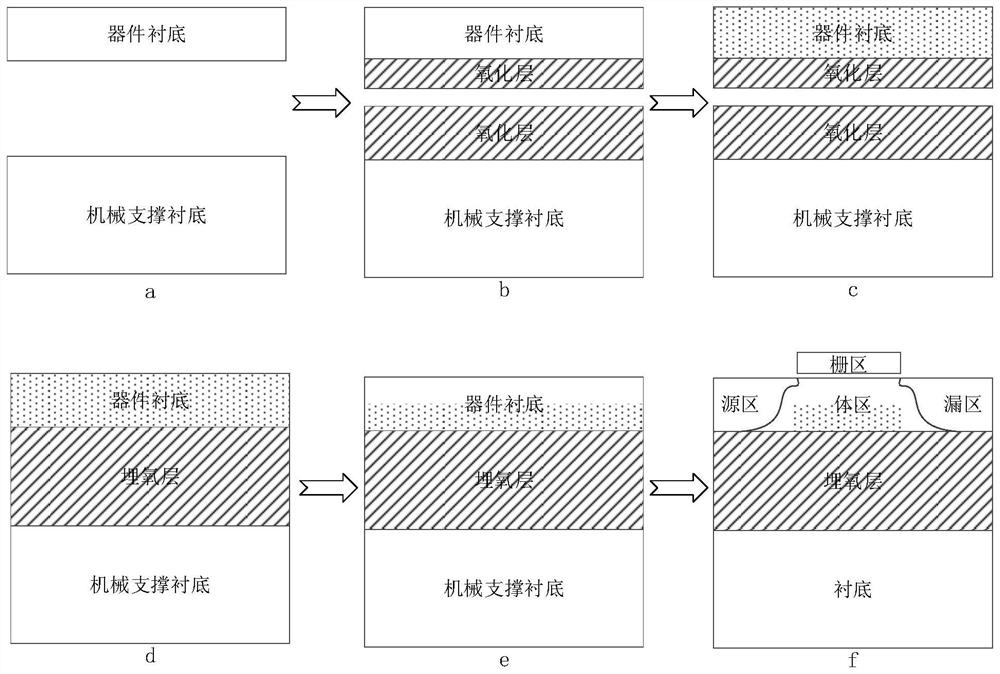

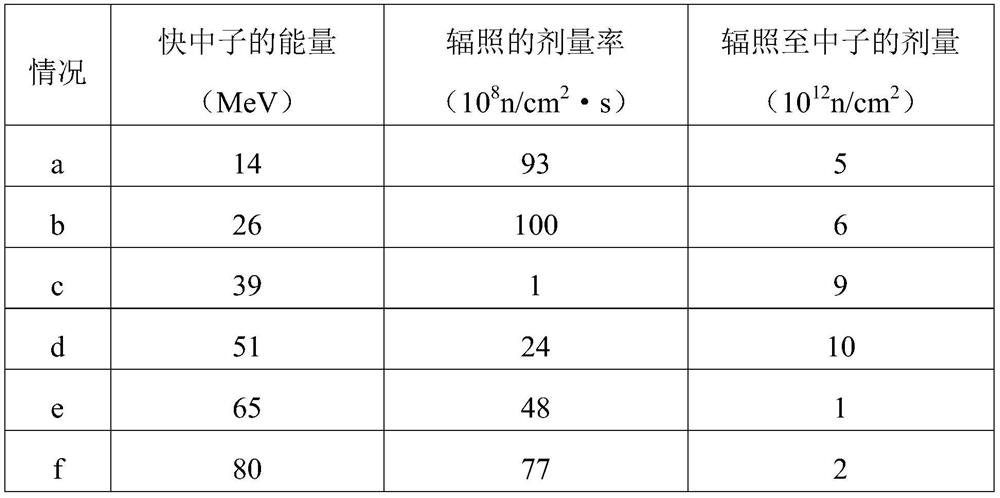

[0038] On the basis of the original preparation method of anti-total dose radiation SOI material, the present invention proposes a new method of introducing deep energy level traps in the body region by using the effect of neutron irradiation, effectively reducing the parasitic bipolar of partially depleted SOI devices Magnification effect. Such as figure 1 As shown, it includes the following steps:

[0039]1. Prepare two monocrystalline silicon substrates, one of which is used as a mechanical support substrate, and the other monocrystalline silicon substrate is used as a device substrate for preparing devices;

[0040] 2. The surface of the device substrate is thermally oxidized to form an oxide layer of the silicon dioxide layer; the surface of the mechanical support substrate is first thermally oxidized to form an oxide layer, and then the CVD method is used to form an oxide layer with a target thickness;

[0041] 3. Si ions are implanted into the oxide layer of the mecha...

Embodiment 1

[0060] A method for preparing an anti-radiation reinforced SOI device based on neutron irradiation, comprising the following steps,

[0061] Step 1, growing an oxide layer on the device substrate and the mechanical support substrate respectively;

[0062] Step 2, irradiating the oxide layer of the device substrate with fast neutrons, so that deep energy level traps are formed in the silicon layer of the device substrate;

[0063] Step 3, bonding the oxide layer of the mechanical support substrate and the oxide layer of the device substrate after fast neutron irradiation to form an integral buried oxide layer;

[0064] Step 4, processing the bonded device substrate so that the surface layer of the silicon layer can be restored to a single crystal state;

[0065] Step 5: Tape out the device on the device substrate whose surface layer of the silicon layer has returned to a single crystal state, and prepare a radiation-resistant and strengthened SOI device based on neutron irradi...

Embodiment 2

[0067] On the basis of Embodiment 1, an oxide layer is formed on the surface of the device substrate by thermal oxidation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com