Aerosol generating device with induction heating tube

An aerosol generation and induction heating technology, which is applied to tobacco and other fields, can solve the problems of low heating efficiency, hot hands, and high power consumption, and achieve the effects of increasing the heating area, good heating effect, and heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

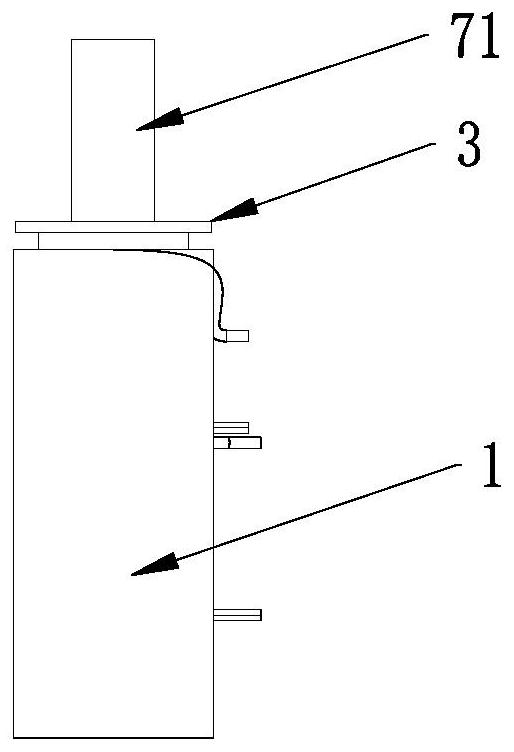

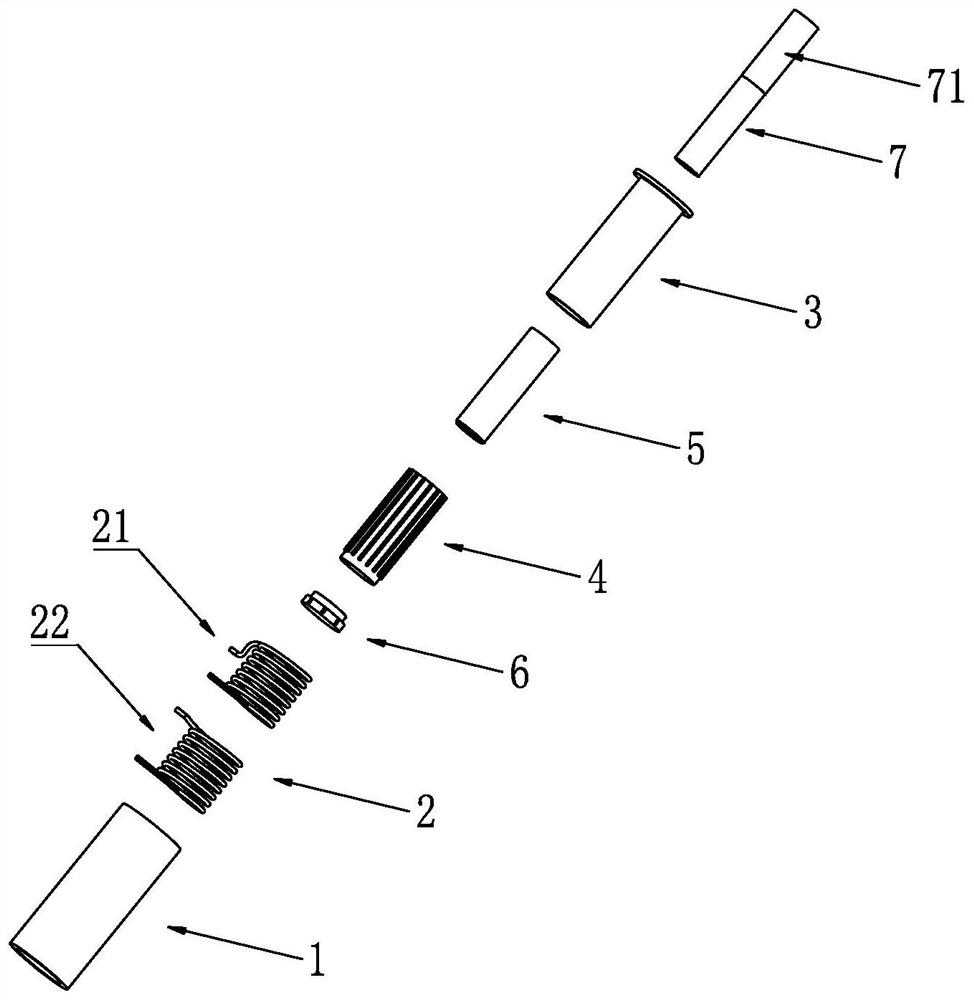

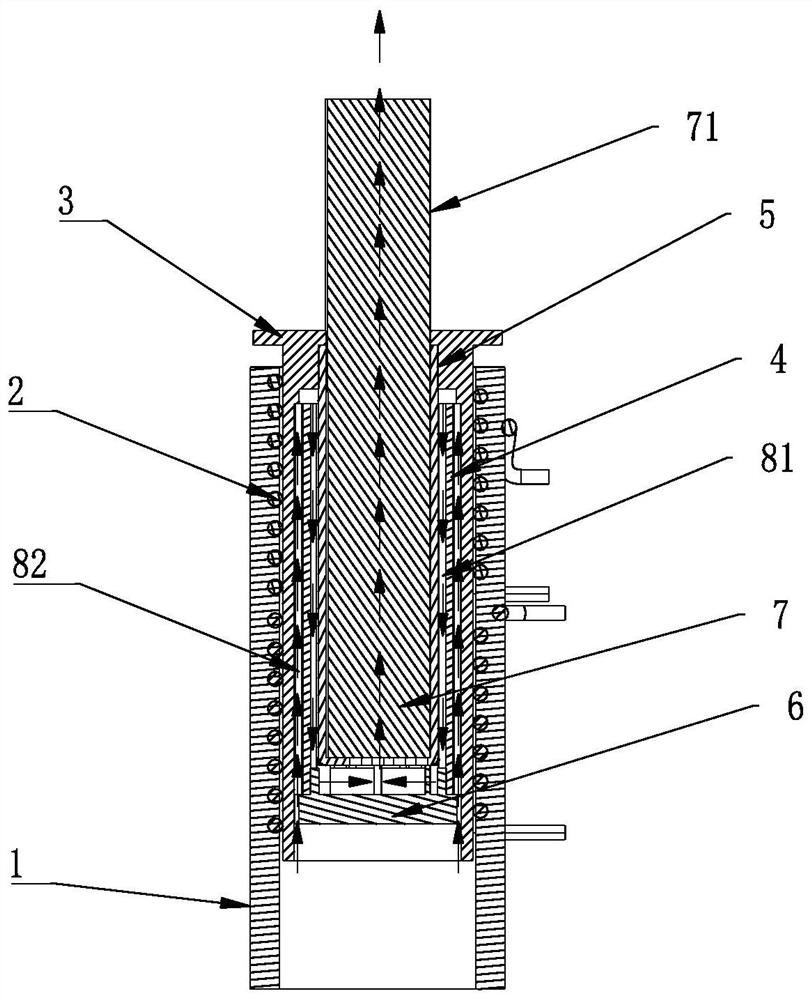

[0046] Such as Figure 1-Figure 3As shown, the present embodiment has an aerosol generating device with an induction heating tube, which is composed of an outer tube 1, an electromagnetic coil 2, an insulating tube 3, an induction heating tube 4 and an inner tube 5 from the outside to the inside, and the bottom of the insulating tube 3 is set With bottom cover6. Wherein, the interior of the inner tube 5 is provided with an inner cavity for accommodating the cigarette 7, and the electromagnetic coil 2 is axially arranged around the outer wall of the insulating tube 3, and the electromagnetic coil 2 can cause the induction heating tube 4 to generate heat when energized. The top of the cigarette 7 is a cigarette holder 71 . The outer tube 1 can be made of heat-insulating material, the insulating tube 3 can be made of heat-insulating insulating material such as PEEK plastic material, and the inner tube 5 can be made of heat-resistant non-magnetic conductive metal or non-metallic ...

Embodiment 2

[0053] Such as Figure 9-Figure 10 As shown, the present embodiment has an aerosol generating device with an induction heating tube, which is composed of an outer tube 1, an electromagnetic coil 2, an insulating tube 3, an induction heating tube 4 and an inner tube 5 from the outside to the inside, and the bottom of the insulating tube 3 is set With bottom cover6. Wherein, the interior of the inner tube 5 is provided with an inner cavity for accommodating the cigarette 7, and the electromagnetic coil 2 is axially arranged around the outer wall of the insulating tube 3, and the electromagnetic coil 2 can cause the induction heating tube 4 to generate heat when energized. The top of the cigarette 7 is a cigarette holder 71 . The outer tube 1 can be made of heat-insulating material, the insulating tube 3 can be made of heat-insulating insulating material such as PEEK plastic material, and the inner tube 5 can be made of heat-resistant non-magnetic conductive metal or non-metalli...

Embodiment 3

[0062] Such as Figure 14-Figure 15 As shown, this embodiment has an aerosol generating device with an induction heating tube, which is composed of an outer tube 1, an electromagnetic coil 2, an insulating tube 3, an induction heating tube 4, an induction heating network 9 and an inner tube 5 from the outside to the inside. A bottom cover 6 is provided at the bottom of the insulating tube 3 . Wherein, the inside of the inner tube 5 is provided with an internal cavity for accommodating the cigarette 7, and the electromagnetic coil 2 is arranged axially around the outer wall of the insulating tube 3, and the electromagnetic coil 2 can make the induction heating tube 4 and the induction heating Net 9 induces heat. The top of the cigarette 7 is a cigarette holder 71 . The outer tube 1 can be made of heat-insulating material, the insulating tube 3 can be made of heat-insulating insulating material such as PEEK plastic material, and the inner tube 5 can be made of heat-resistant n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com