Cooking utensil and processing device

A technology of cooking utensils and processing devices, which is applied to the structure of cooking utensils, cooking utensils, household utensils, etc., and can solve problems such as the decline in the condensation effect of condensing parts, the rise of its own temperature, and the inability to continue to effectively condense oil fumes, water mist and other media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

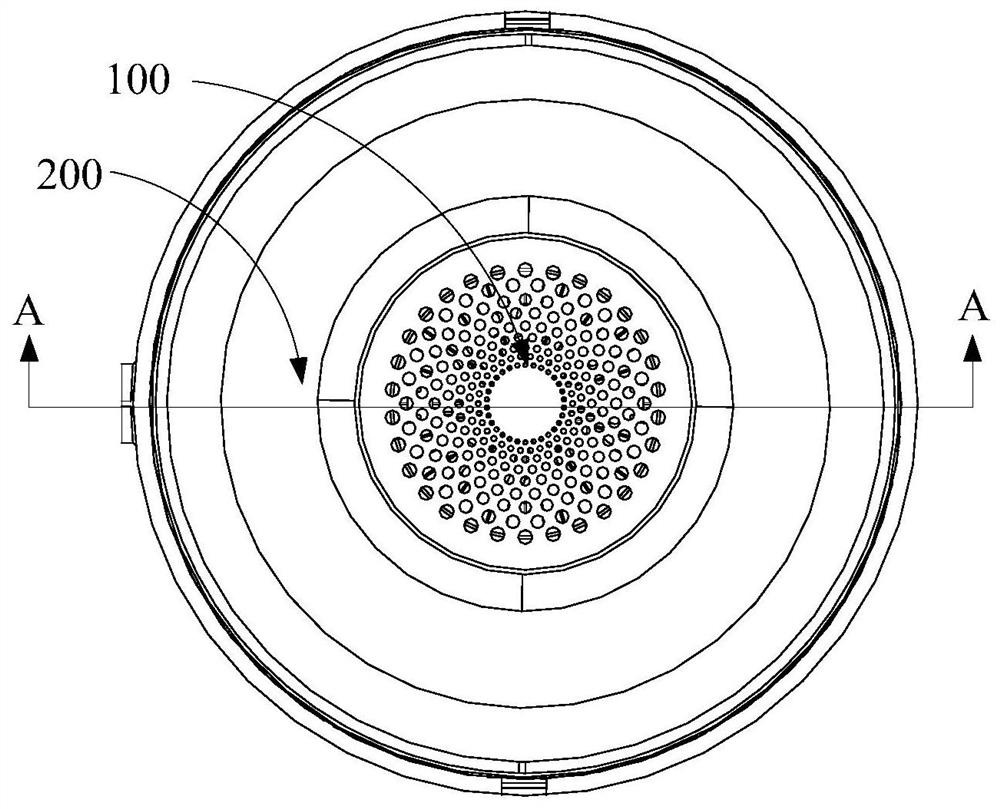

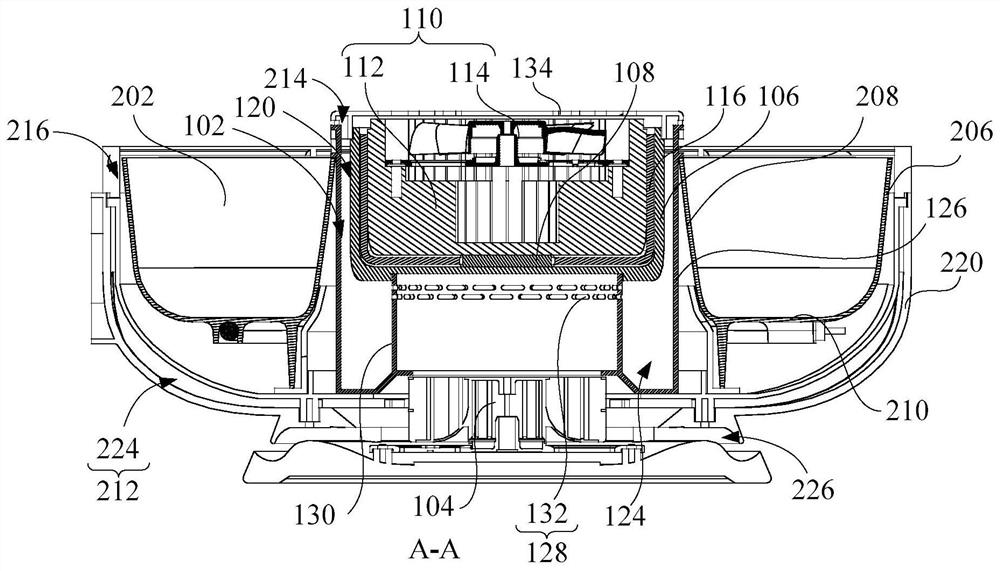

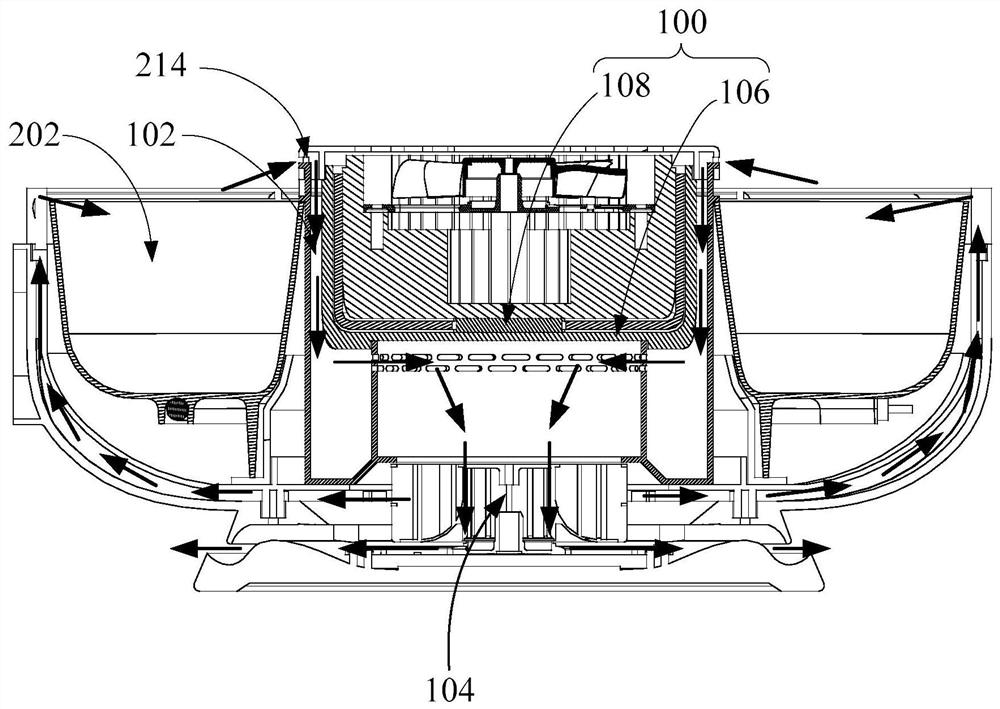

[0094] like figure 1 , figure 2 with image 3 Disted, where image 3 The center arrow indicates a gas flow direction. The first embodiment of the present invention proposes a cooking instrument, and the cooking appliance includes: a pot of pottery 200, and the cooking apparatus 100, the processing apparatus 100 includes: channel 102, drive member 104, Condensation member 106 and the refrigeration member 108. The drive member 104 is configured to drive the gas, and cause the gas to flow along the passage 102, the condensed member 106 can condense the gas in the passage 102, which in turn realizes the condensation and purification of the gas in the gas, water mist, etc. The component 108 and the condensed member 106 can be heat transfer, which effectively reduces the temperature of the condensed member 106, and then enhances the condensation of the condensation member 106.

[0095] Specifically, such as image 3 As shown in, in particular, during use of the cooking instrument, the cine...

Embodiment 2

[0103] like figure 1 , figure 2 with image 3 Disted, where image 3 The arrows indicate the direction of gas flow, a second embodiment of the present invention provides a cooking appliance, the cooking appliance comprising: a pot 200, 200 is provided with a pot processing device 100, processing device 100 comprises a channel 102, drive member 104, condensing member 106, the cooling member 108 and the heat sink 110. Wherein the drive member 104 is configured to drive the gas, and the gas flow along the passageway 102 such that condensation member 106 can be condensed in the process gas passageway 102, and then realize the gaseous medium condensed smoke, mist and other add purification, refrigeration condensing member 108 between the member 106 and the heat transfer can be effectively reduced temperature of the condensing member 106, thereby enhancing the condensing effect of the condensing member 106; 110 configured to heat sink the cooling member 108 is adapted to dissipate heat.

...

Embodiment 3

[0116] like figure 1 , figure 2 with image 3 Disted, where image 3 The arrows indicate the direction of gas flow, a third embodiment of the present invention proposes a cooking appliance, the cooking appliance comprising: a pot 200, 200 is provided with a pot processing device 100, processing device 100 comprises a channel 102, drive member 104, condensing member 106 and cooling member 108. Wherein the drive member 104 is configured to drive the gas, and the gas flow along the passageway 102 such that condensation member 106 can be condensed in the process gas passageway 102, and then realize the gaseous medium condensed smoke, mist and other add purification, refrigeration condensing member 108 between the member 106 and the heat transfer can be effectively reduced temperature of the condensing member 106, thereby enhancing the condensing effect of the condensing member 106; cooling member 108 having a first end and a second end, the first end 106 of the condensing member between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com