Non-circular filter element material and rewinding method thereof

A non-circular, filter element technology, applied in the field of non-circular filter element core material and its rewinding, can solve the problems of inconvenient operation, difficulty in operation, dirty working environment, and excessive pause times, so as to avoid uneven products. , The operation is simple and fast, and the effect of controlling product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

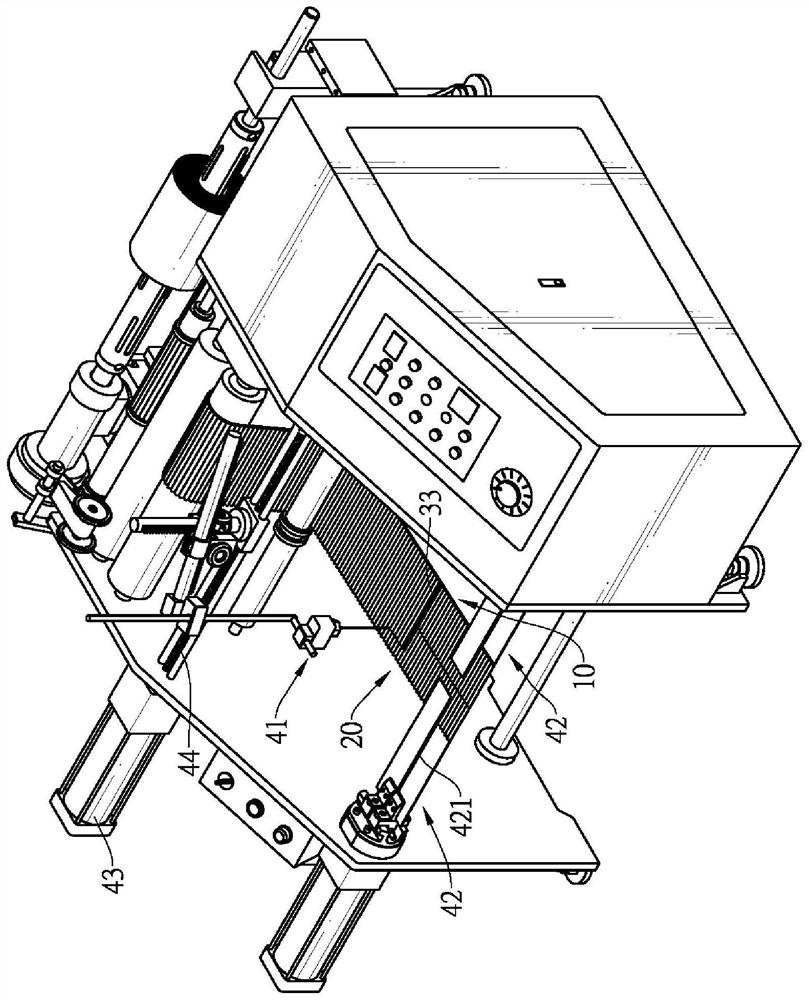

[0042] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

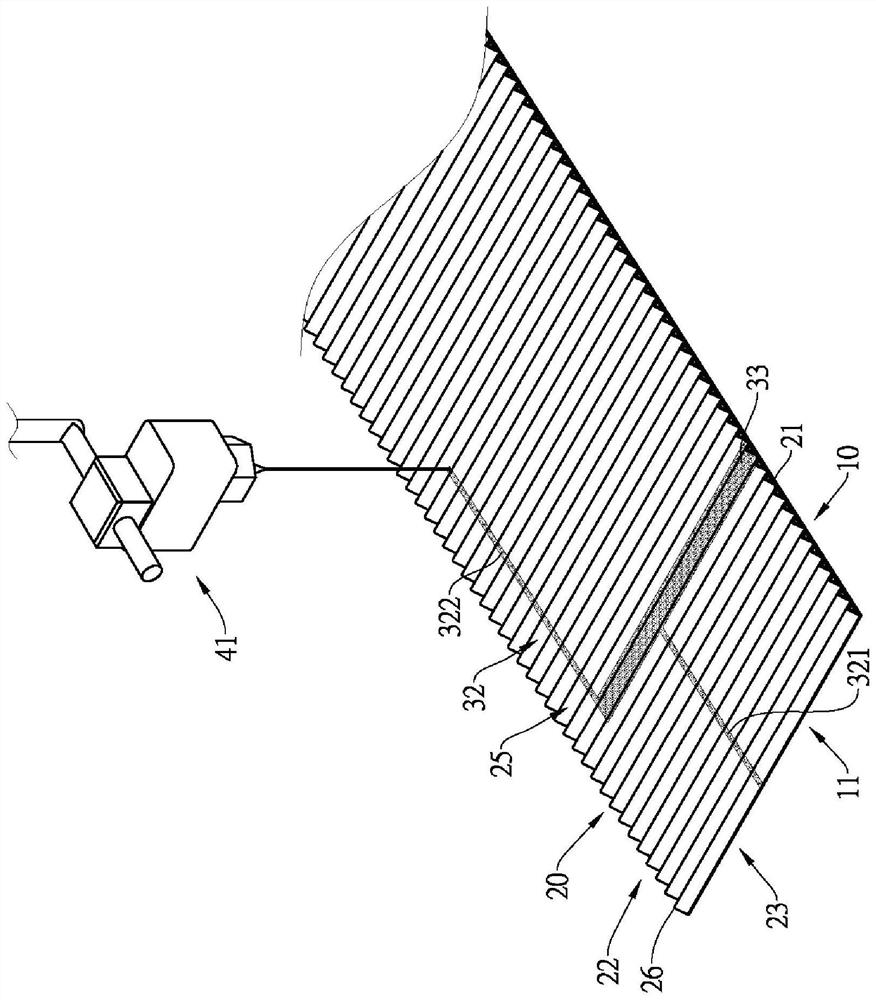

[0043] see Figure 13 As shown, the rewinding method of the non-circular filter core material of the present invention includes the following steps: combining the wave-shaped separation material and the plane separation material S1, coating the edge-sealing adhesive layer S2 and winding S3. The non-circular filter core material of the present invention preferably refers to a racetrack-shaped filter core material, but it can also be oval and other shapes, as long as it is not circular.

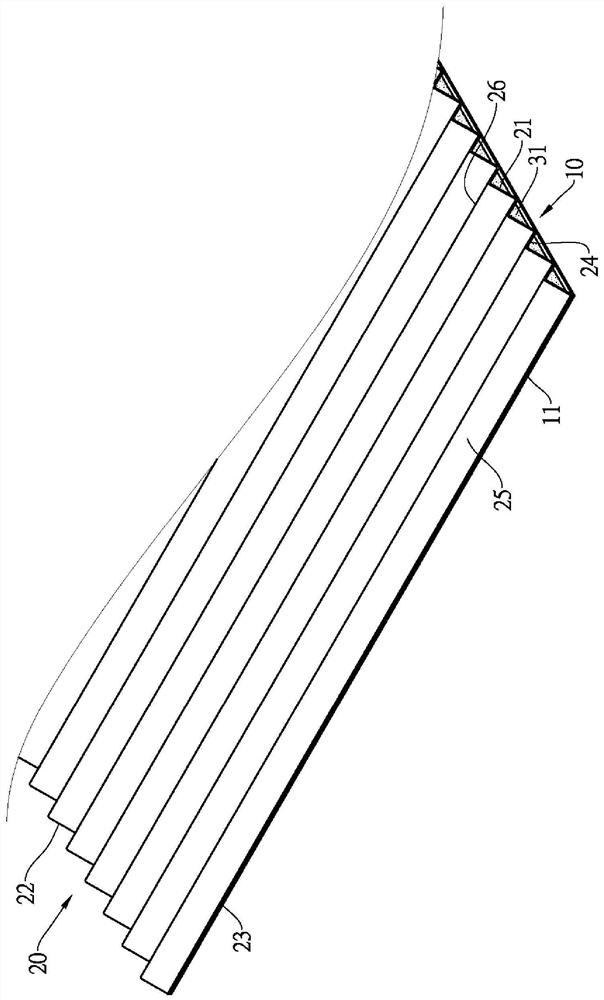

[0044] Combination of corrugated and flat separators S1: see figure 2 As shown, first prepare a planar separation material 10 and a wave-shaped separation material 20 for separating suspended pollutants; the side of the planar separation materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com