Waste collecting device for meat cutting processing

A technology for waste collection and meat, applied in blood collection/blood stirring device, application, solid separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

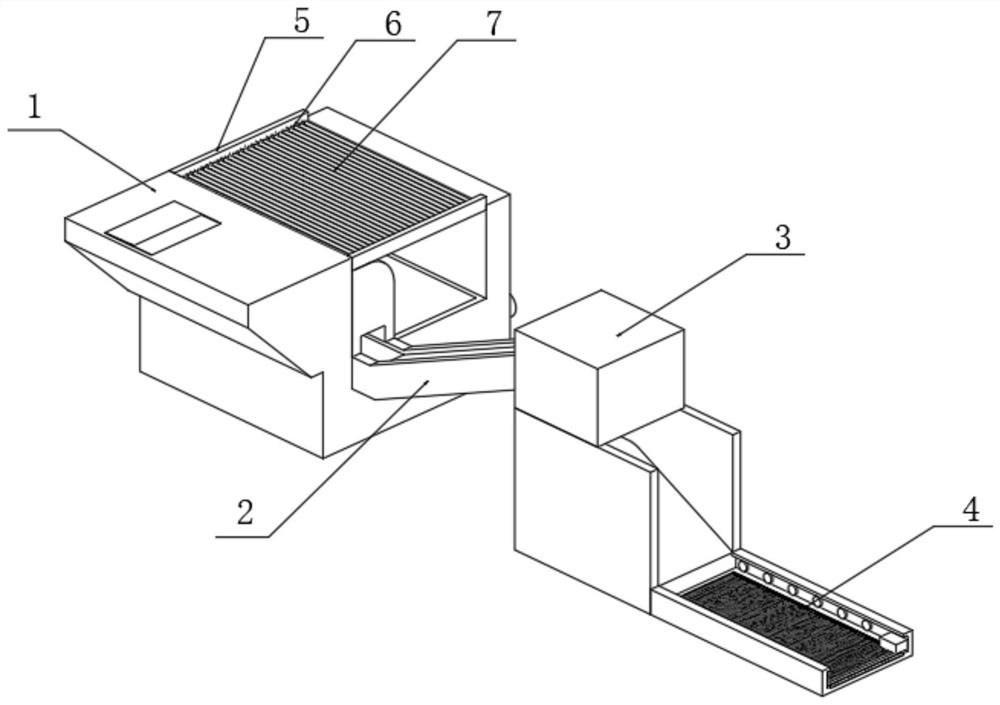

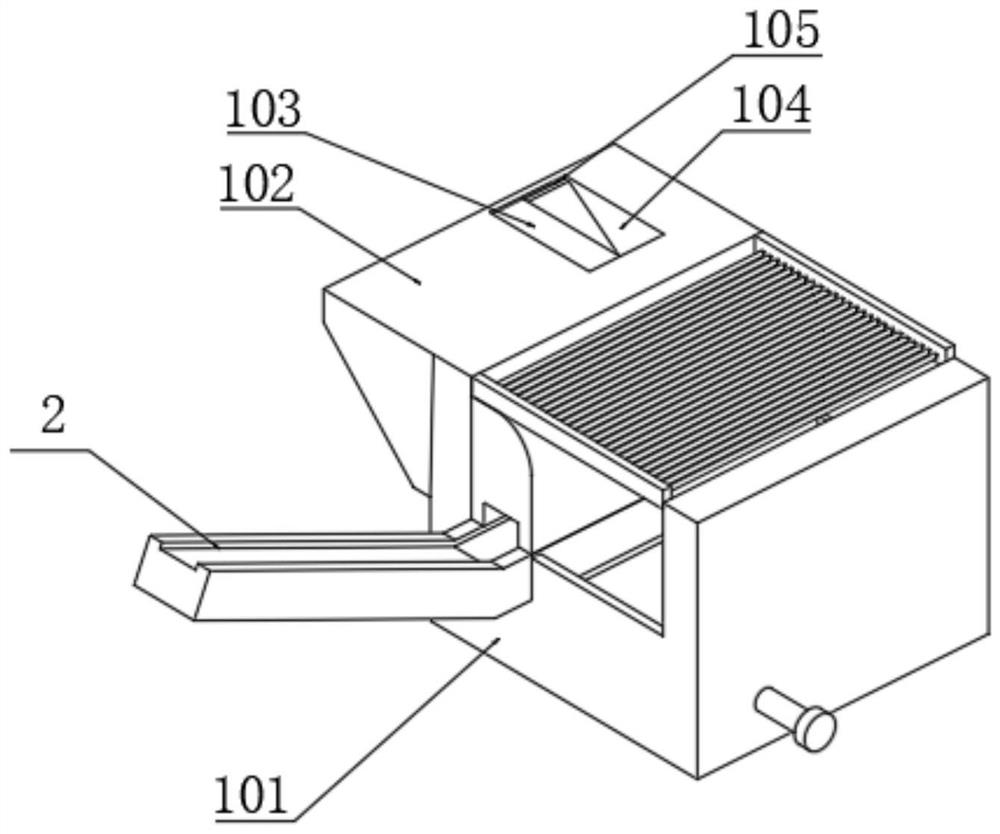

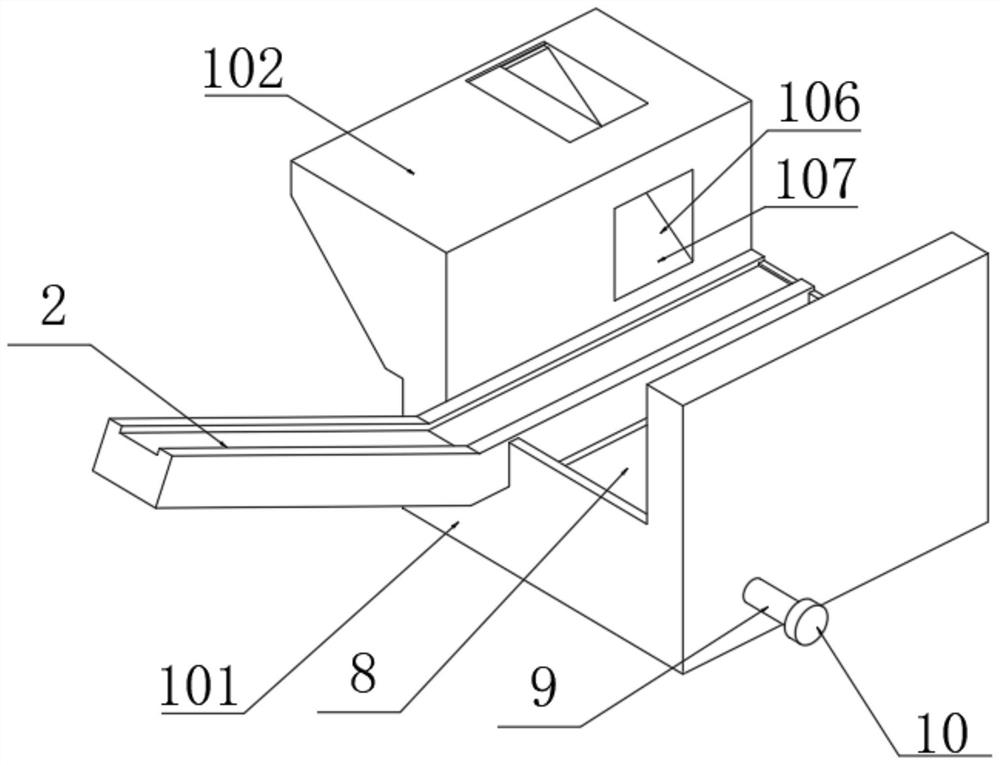

[0034] like Figure 1-11 As shown, a waste collection device for meat segmentation processing includes a blanking assembly 1, the blanking assembly 1 includes a blanking cabinet 101, and the upper side of the blanking cabinet 101 is fixedly connected with two limiting plates 5, the limiting plate 5 are movably connected by a number of third rotating rods 6 in the middle, each third rotating rod 6 is fixedly connected with a rotating shaft 7 outside, and a water tank 8 is provided at the bottom of the feeding cabinet 101, and the water outlet of the water tank 8 is fixedly connected with a water outlet pipe 9, The outlet pipe 9 passes through the outer wall of the feeding cabinet 101 and is movably connected with a round cover 10, the feeding assembly 1 is fixedly connected with the conveyor 2, and the side of the conveyor 2 away from the feeding assembly 1 is fixedly connected with the crushing assembly 3, and the crushing assembly 3 outputs The end is fixedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com