High-precision rapid driving mechanism for vertical shaft of numerical control machine tool

A technology of CNC machine tools and driving mechanisms, which is applied to metal processing machinery parts, maintenance and safety accessories, and metal processing equipment, etc. Problems such as large thermal deformation error, to achieve the effect of high precision and high dynamic characteristic movement, good inertia matching, and reduction of transmission clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

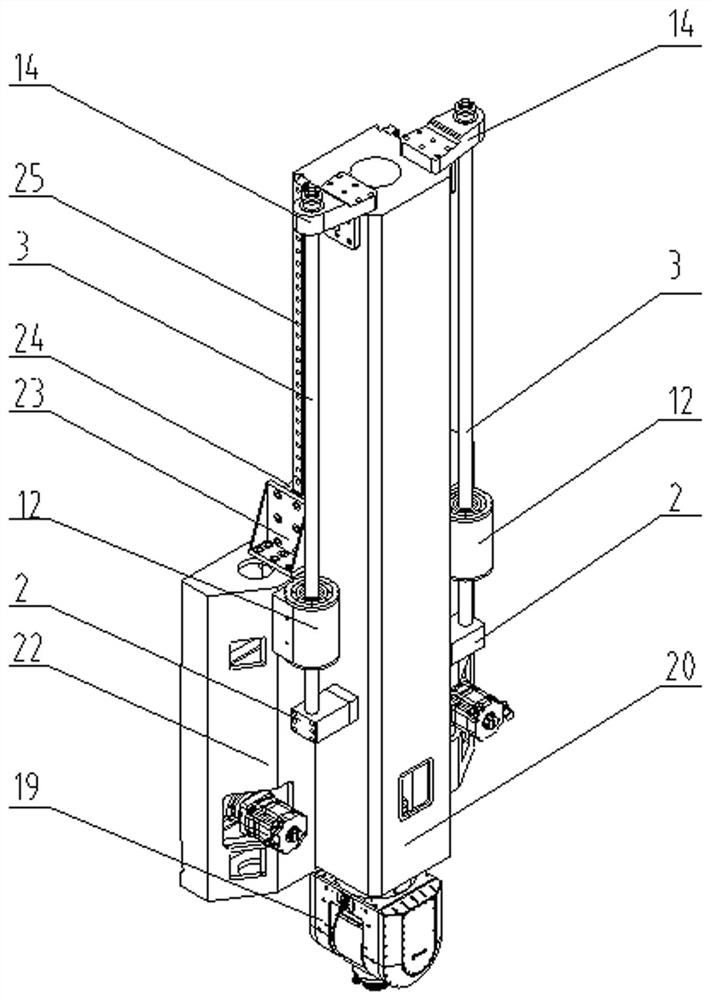

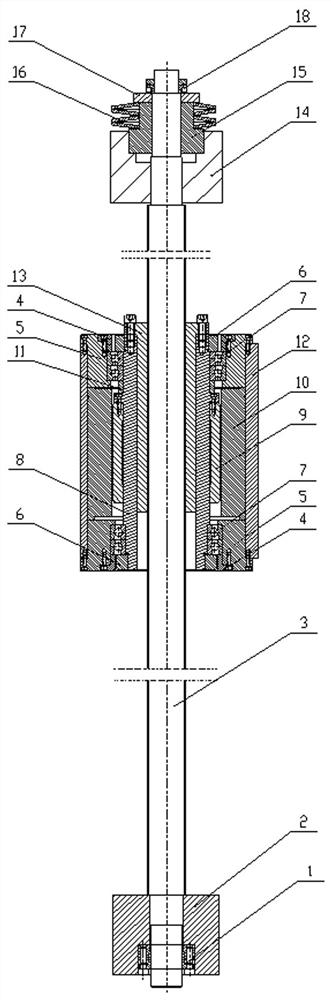

[0018] Such as figure 1 As shown, a high-precision fast drive mechanism for the vertical axis of a CNC machine tool includes a slide plate 22 and a slide rail 20, the ram 20 slides vertically along the outer surface of the slide plate 22, the bottom of the ram 20 is connected to the cutter 19, and the ram 20 The left and right sides of the ram 20 are symmetrically provided with linear guide rails 25, and the linear guide rails 25 are slidably connected with the slide plate 22; the upper support seats 14 of the screw are symmetrically arranged on the left and right sides of the top of the ram 20, and the leading screws are symmetrically arranged on the left and right sides of the middle part of the ram 20. The lower support base 2 connects the lead screw 3 between the upper support base 14 of the lead screw on the same side and the lower support base 2 of the lead screw. The lead screw 3 is a hollow structure for cooling water circulation, and each lead screw 3 is coaxially matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com