Working method of tail car receiving hopper of bucket wheel machine

A working method and technology of receiving hoppers, which are applied in the directions of conveyor objects, transportation and packaging, loading/unloading, etc., which can solve the problem of lack of anti-leakage ability of bulk materials, leakage and dust of bulk materials, and inability to guarantee anti-leakage capabilities of bulk materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

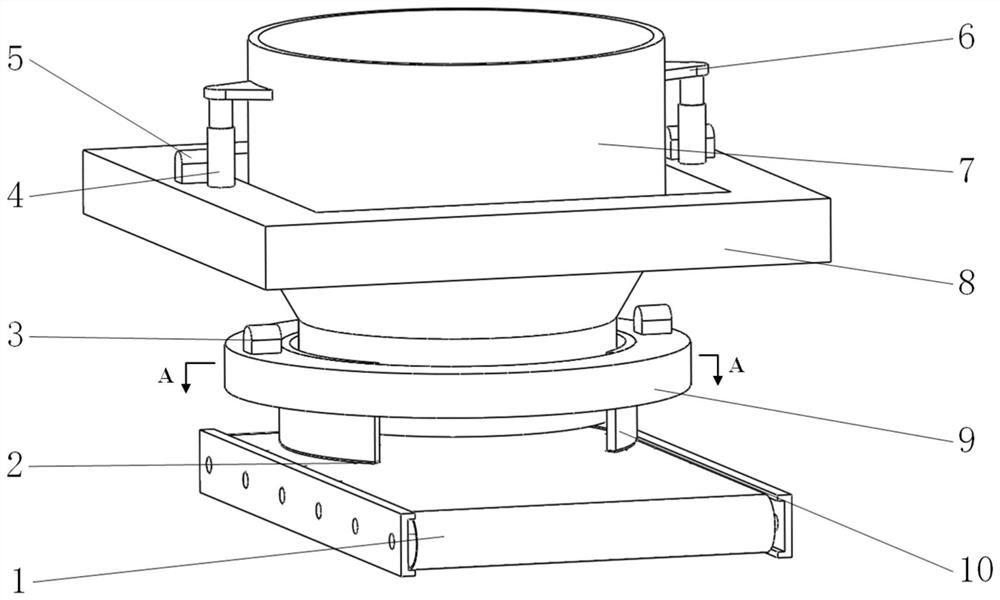

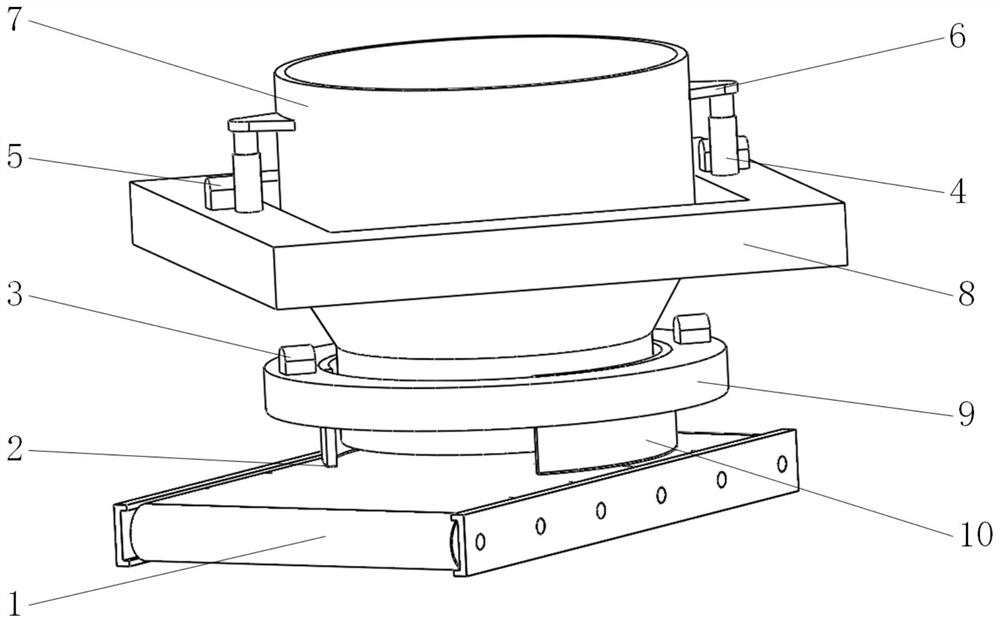

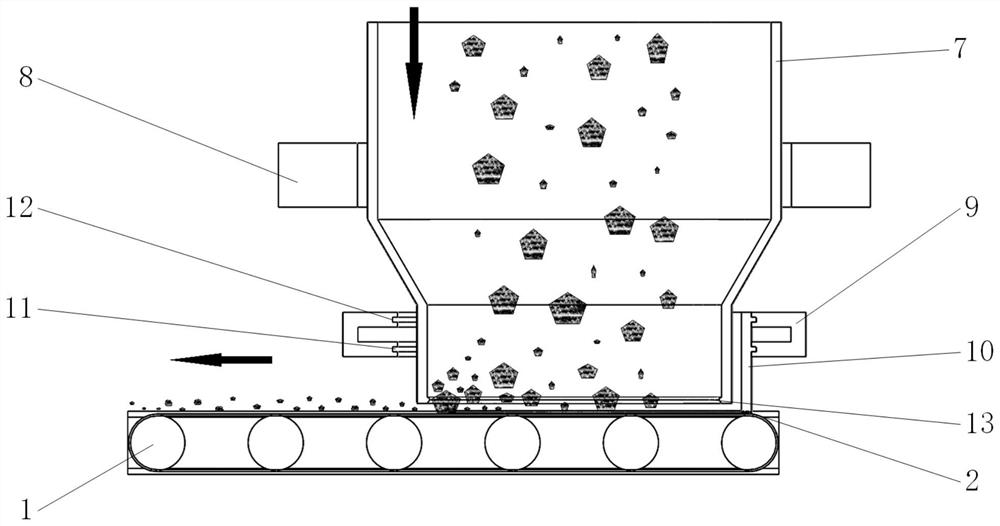

[0026] As shown in the figure: a working method of the tail car receiving hopper of the bucket wheel machine, the tail car receiving hopper of the bucket wheel machine is arranged on the tail car conveyor belt 1, including the receiving hopper 7, the receiving hopper ear plate 6, the receiving hopper Bracket 8, receiving hopper hydraulic lifting device 4, receiving hopper hydraulic lifting drive device 5, rotatable material retaining cover 10, material retaining cover rotating drive device 3, material retaining cover bracket 9, pressure sensing belt 13; the receiving hopper hydraulic pressure The lifting device 4 is fixed on the receiving hopper support 8, and the other end cooperates with the receiving hopper ear plate 6 to arrange the receiving hopper 7 on the tail car conveyor belt 1; the receiving hopper hydraulic lifting drive device 5 is also fixed on the receiving hopper support 8, the hydraulic rod of the hopper hydraulic lifting drive device 5 stretches to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com