Cement bag damping cutting system

A cutting system, cement bag technology, used in springs/shock absorbers, smoke removal, containers, etc., can solve problems such as bad environment, a lot of cement dust, impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

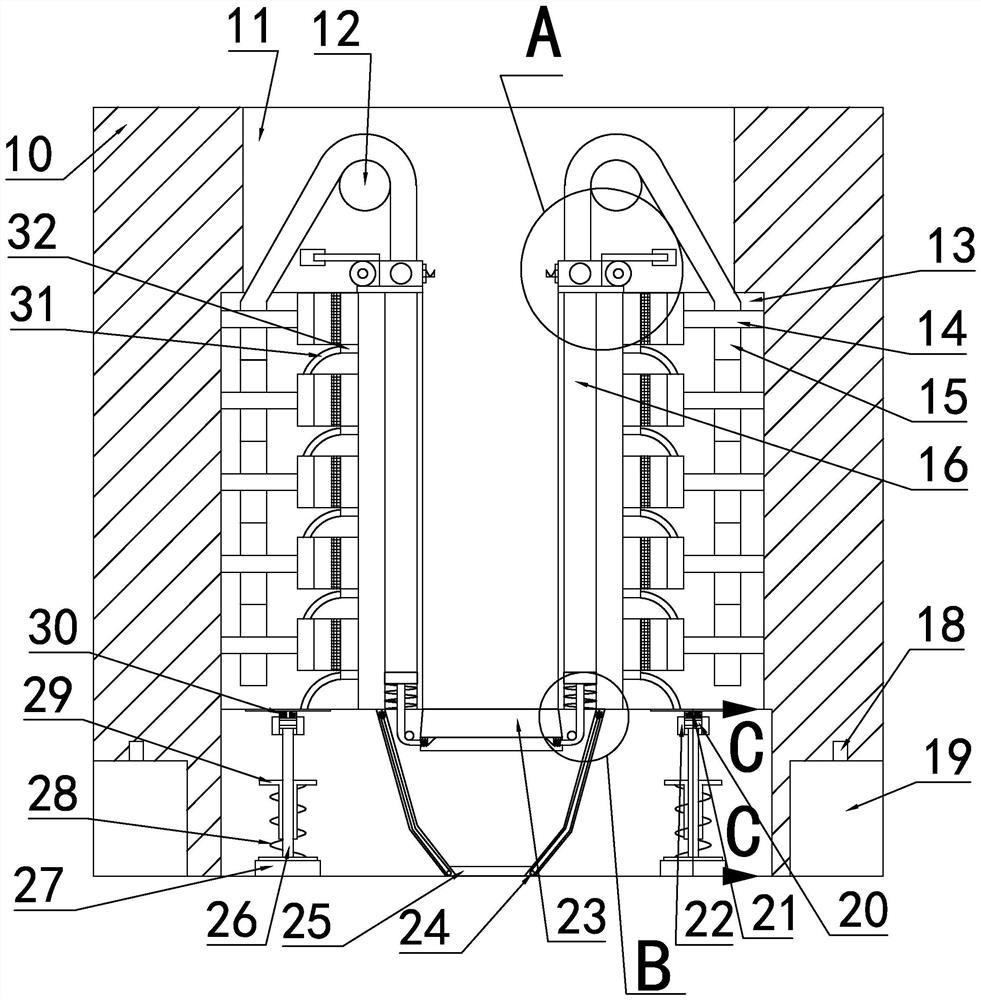

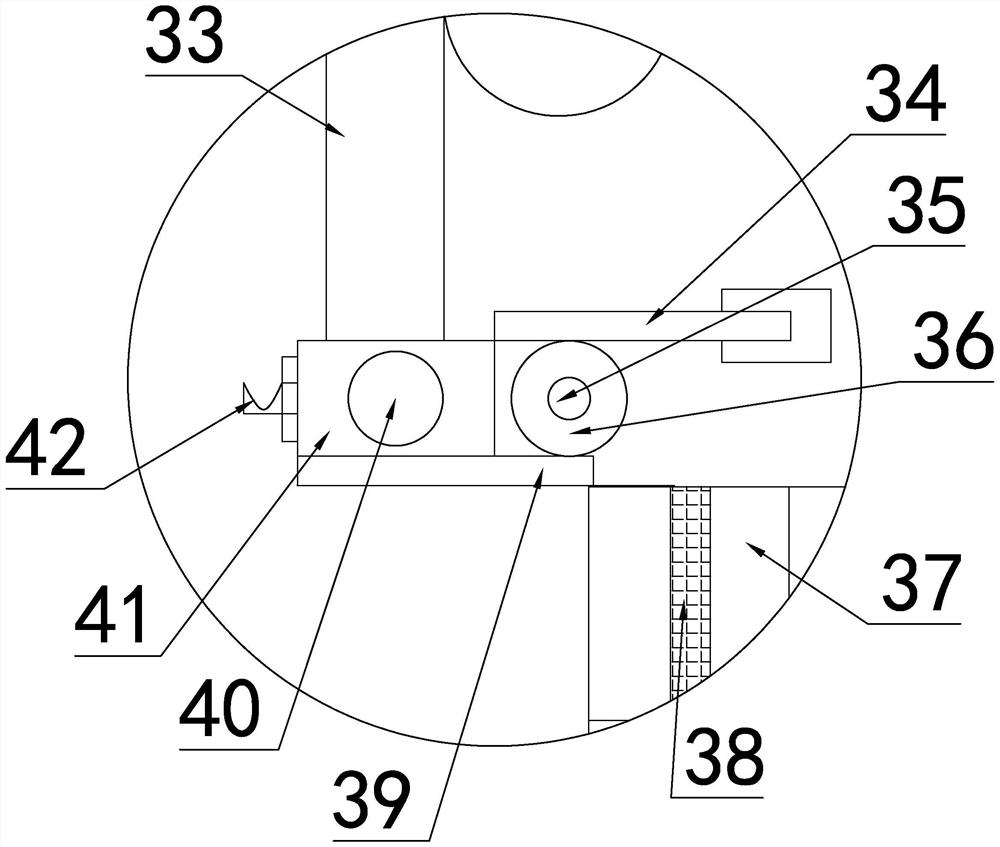

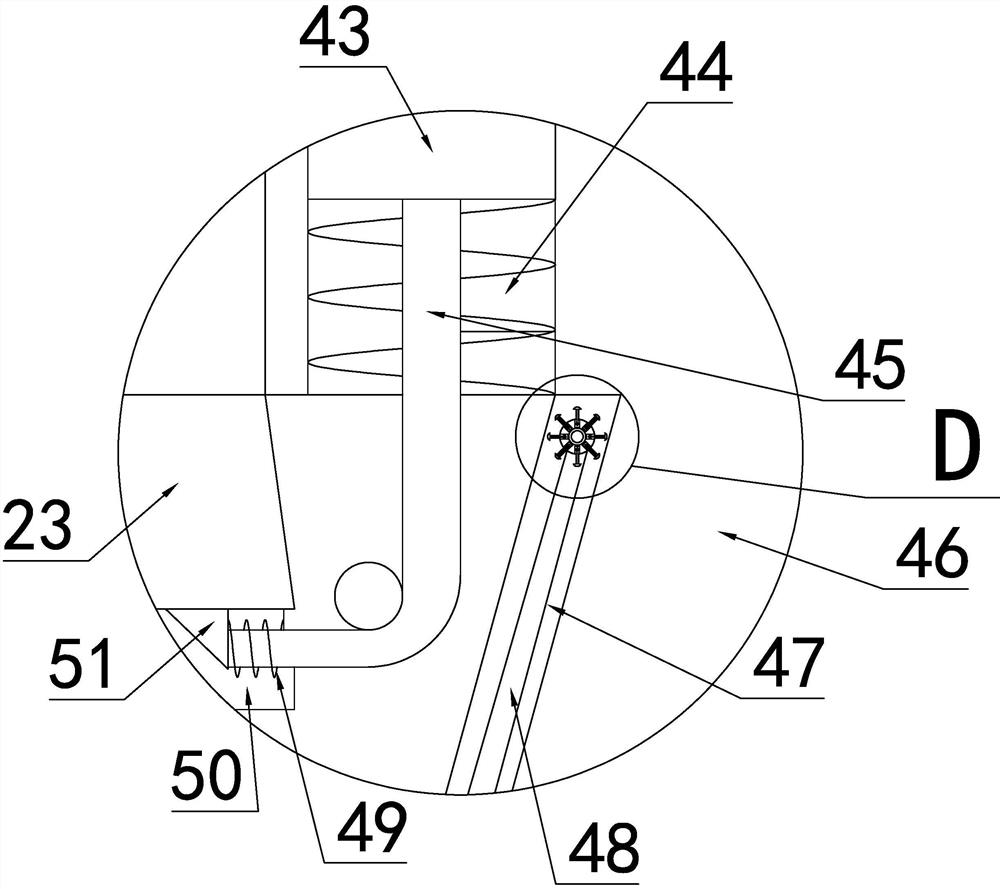

[0024] Such as figure 1 As shown, a cement bag shock-absorbing cutting system includes a housing 10, the upper end wall of the housing 10 is fixedly provided with an active chamber 11, the active chamber 11 is provided with a connection and lowering device, and the left and right ends of the housing 10 are fixedly provided with suction chambers. Ash chamber 13, dust suction chamber 13 is provided with ash suction device, the lower end wall of active chamber 11 is fixed with stuck chamber 23, the left and right end walls of stuck chamber 23 are fixedly provided with two identical pressure chambers 44, stuck chamber 23 The lower end wall is fixedly provided with a cutting chamber 50, the cutting chamber 50, the stuck chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com