Support-free fusion electrostatic spinning direct writing device of tiny three-dimensional structure

A three-dimensional structure, electrospinning technology, applied in fiber processing, textile and paper making, filament/thread forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

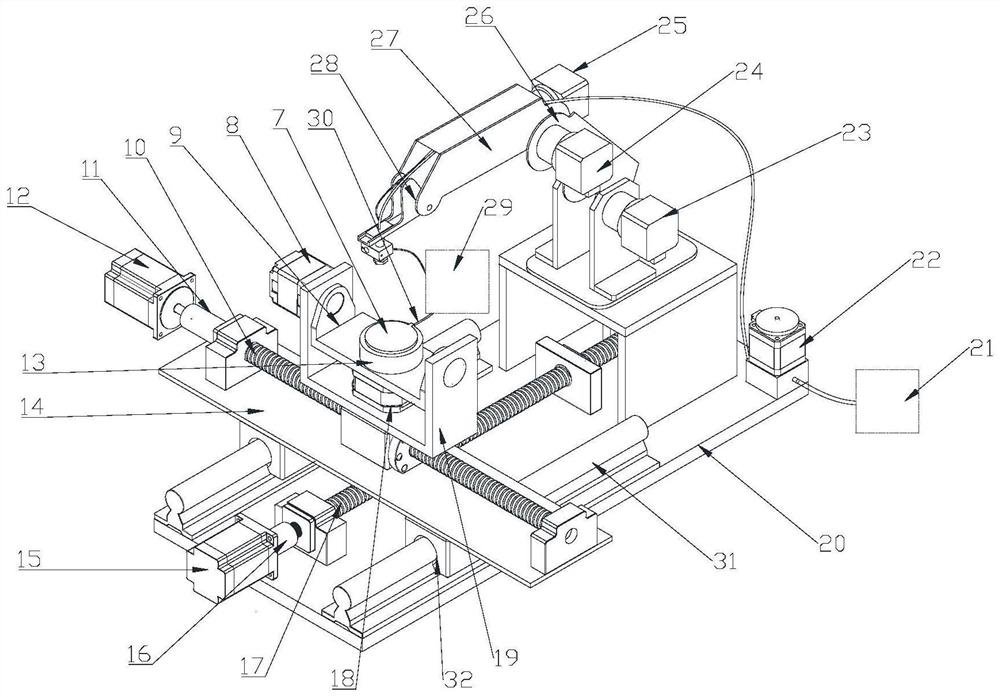

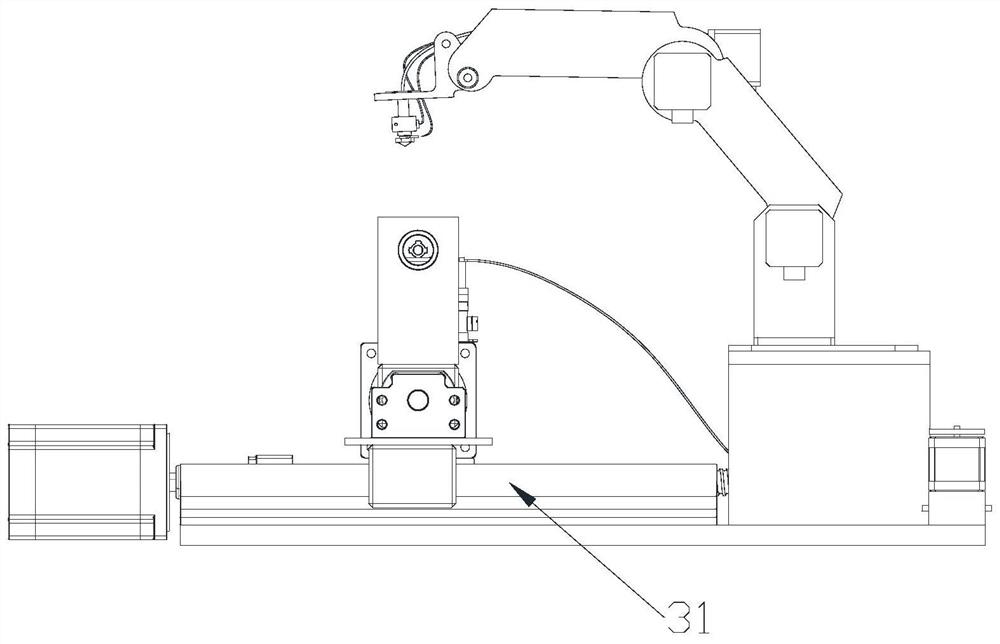

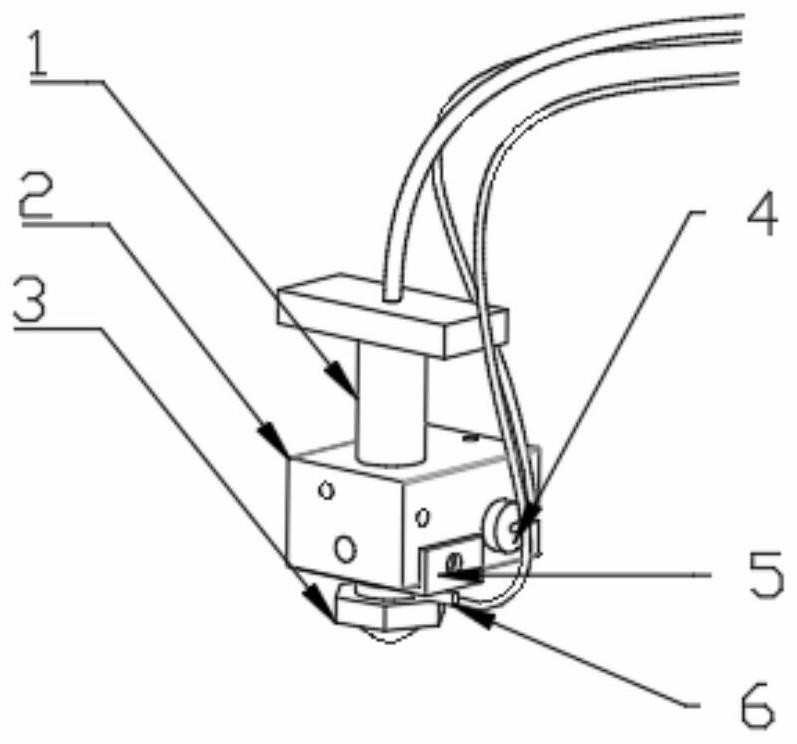

[0036] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0037] see figure 1 , figure 2 and image 3 , the present embodiment is a kind of unsupported melt electrospinning direct-writing device with tiny three-dimensional structure, including frame 20, Y-axis horizontal motion motor 15, Y-axis coupling 16, Y-axis precision ball screw 17, Y-axis horizontal Motion platform 14, X-axis precision ball screw 10, X-axis coupling 11, X-axis horizontal motion motor 12, X-axis horizontal motion platform 19, X-axis rotary platform 9, X-axis rotary motor 8, Z-axis rotary insulation platform 13. Z-axis rotating motor 18, part receiving plate 7, mechanical arm and electrospinning nozzle 3,

[0038] The Y-axis horizontal motion motor 15 and the Y-axis precision ball screw 17 are arranged on the frame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com