Double thread ring sewing machine

A sewing machine and sewing technology, applied in the direction of sewing machine components, sewing machine needle holders, sewing machine housings, etc., can solve the problems of difficult maintenance work, complicated manufacturing process, and inconvenient users, and achieve simple manufacturing process and maintenance work. Convenient and simple, easy to disassemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

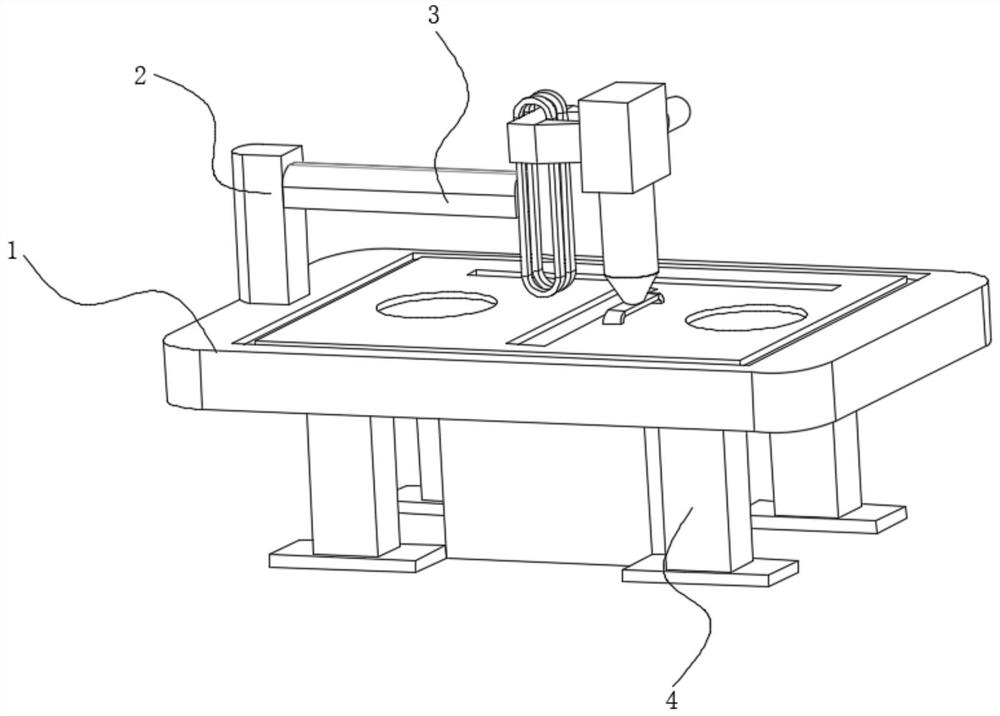

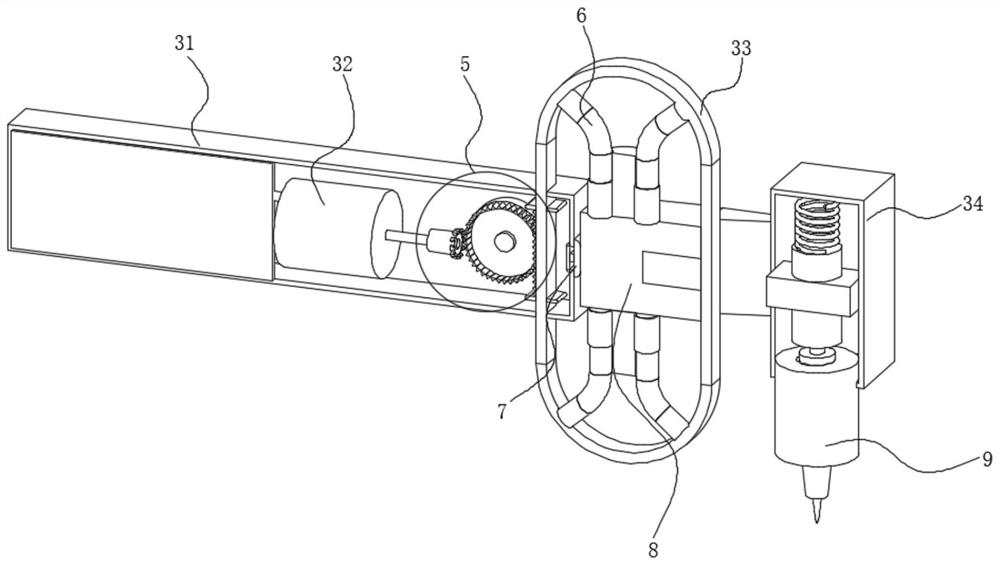

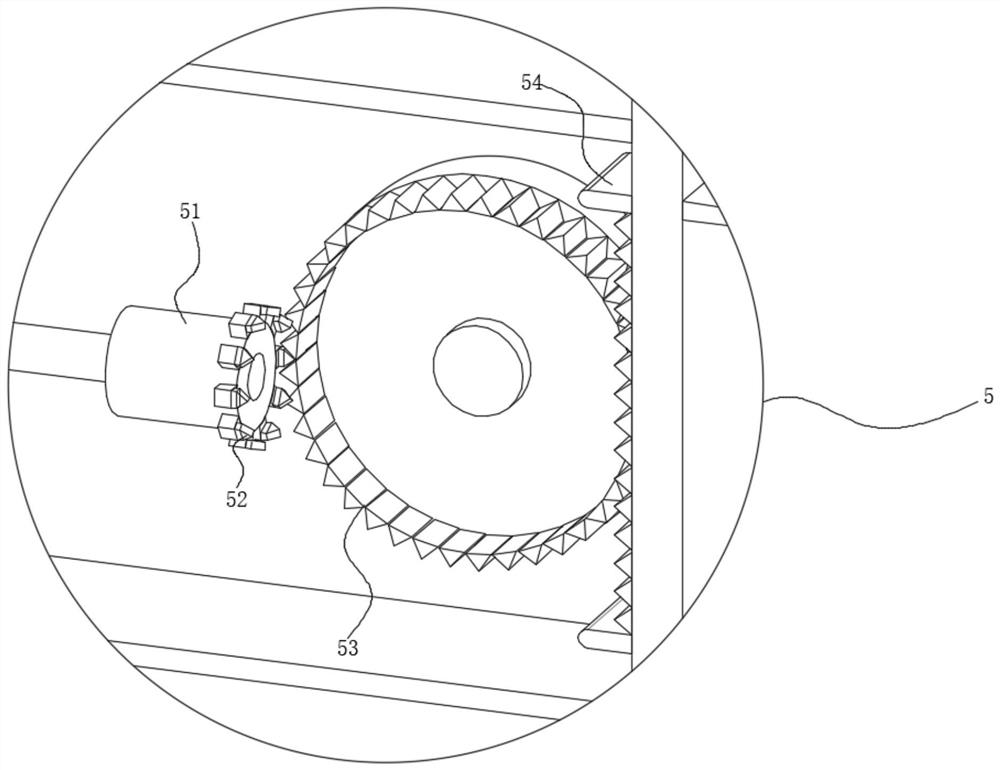

[0022] use Figure 1-Figure 7 A double-thread loop sewing machine according to an embodiment of the present invention will be described below.

[0023] Such as Figure 1-Figure 7 As shown, a double-thread loop sewing machine according to the present invention includes a sewing table 1, a connecting arm 2 is movably connected to the left side of the upper surface of the sewing table 1, and the bottom end of the connecting arm 2 passes through the sewing table 1. The outer surface, the bottom end of the connecting arm 2 is fixedly connected with the inner cavity of the sewing table 1, the left side of the outer surface of the connecting arm 2 is fixedly connected with the sewing arm 3, and the upper surface of the sewing table 1 is movably connected with a load Object plate, the lower surface of the sewing table 1 is fixedly connected with support legs 4, and the middle part of the lower surface of the sewing table 1 is fixedly connected with a power box. Compared with the gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com