Noise reduction type building construction tamping equipment

A building construction and noise reduction technology, applied in construction, infrastructure engineering, instruments, etc., can solve the problems of unstable center of gravity of tamping machine, eardrum damage, overturning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

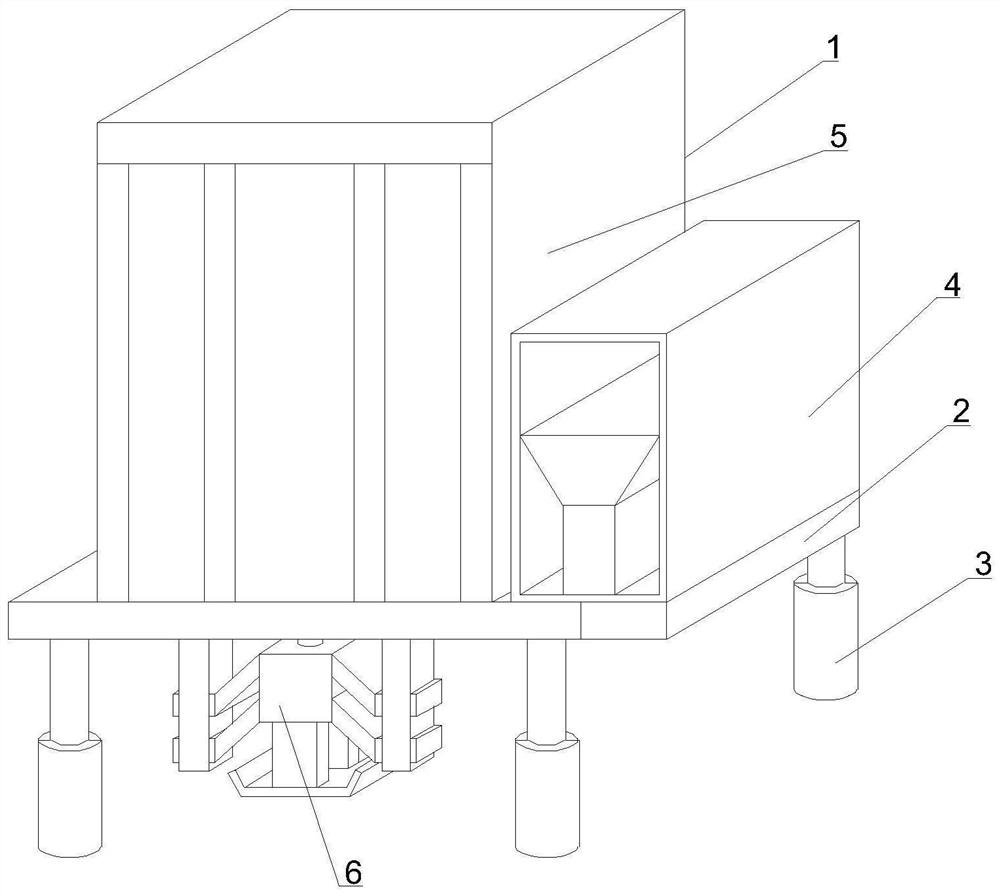

[0043] Such as Figure 1-9 As shown, the present invention provides a noise reduction type building construction tamping equipment, including a tamping equipment body 1, a workbench 2, a support foot 3 and a cooler 4, the tamping equipment body 1 includes a workbench 2, and the lower surface of the workbench 2 The upper is fixedly connected with support feet 3, the outer surface of the workbench 2 is fixedly connected with a cooler 4, the outer surface of the workbench 2 is fixedly connected with a power supply box 5, and the lower surface of the workbench 2 is fixedly connected with a compactor 6.

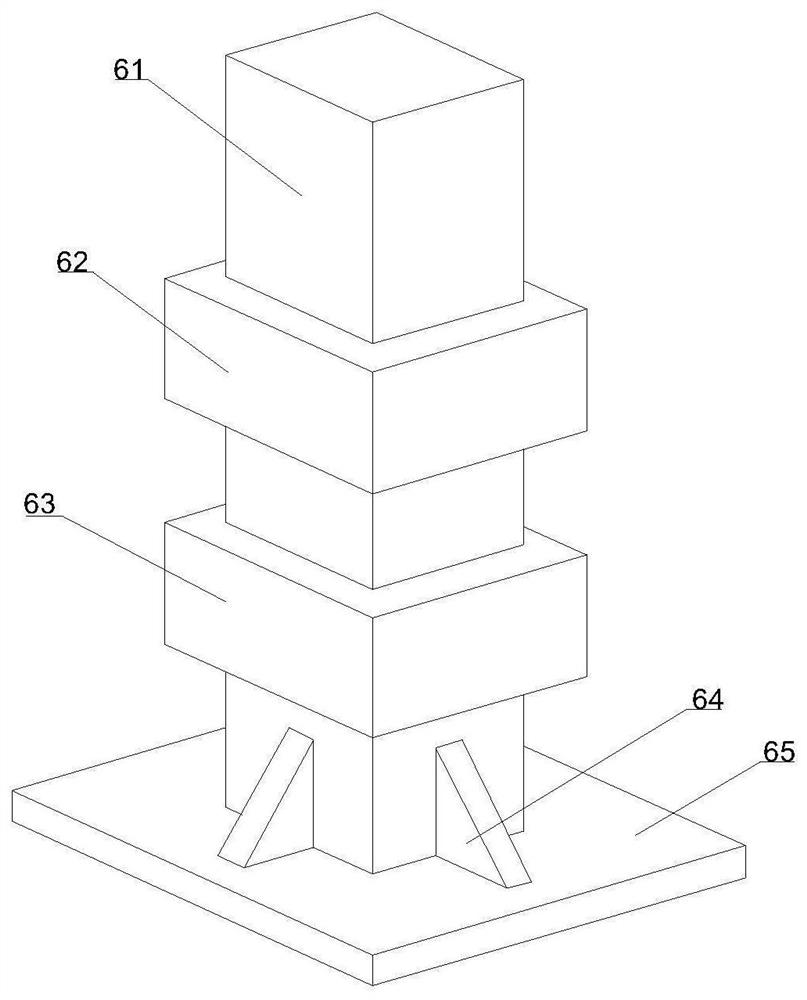

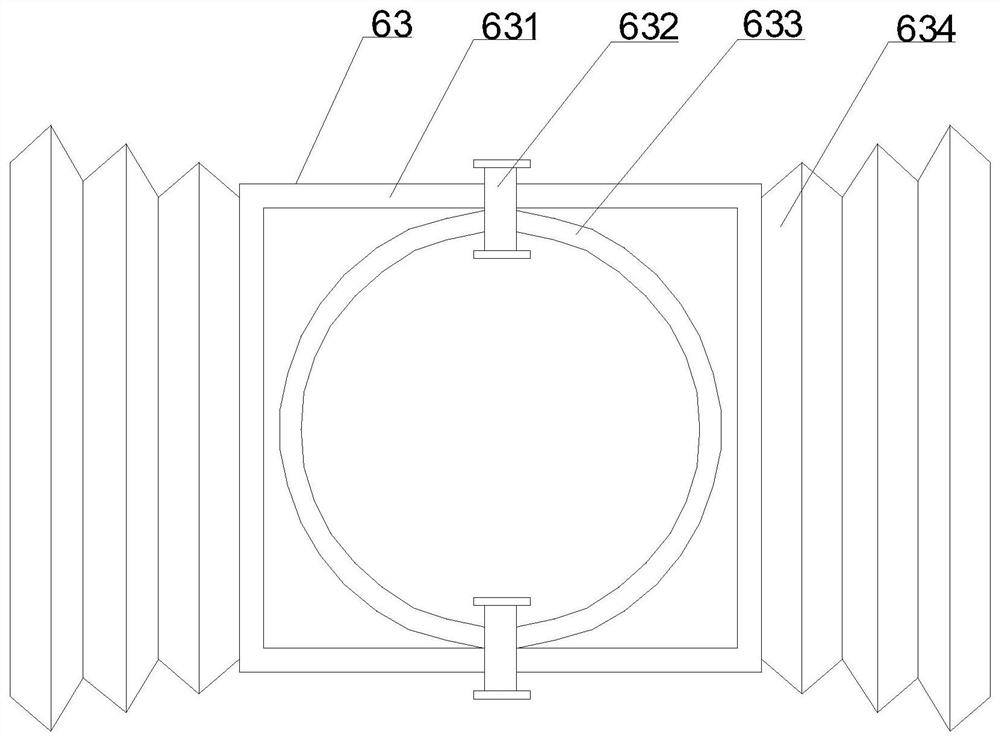

[0044] The compacting machine 6 includes a sliding column 61, and a noise reduction mechanism 63 is movably connected to the outer surface of the sliding column 61.

[0045] The support foot 3 includes a support column 31 , and a triangular cone 32 is fixedly connected to one end of the support column 31 .

[0046] In this embodiment, the tamping machine is strengthened through t...

Embodiment 2

[0050] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the sound-absorbing block 625 includes a sliding column 2 6251, and a cylindrical rod 6252 is fixedly connected to the outer surface of the sliding column 6251, and the cylindrical rod 6252 An internal post 6253 is arranged inside, and a sound hole 6254 is opened on the outer surface of the internal post 6253 , and a sound-absorbing casing 6255 is movably connected to the outer surface of the cylindrical rod 6252 .

[0051] In this embodiment, the internal connection column 6253 is used to absorb the noise generated by the tamping machine during operation, and then the noise is differentiated and transmitted through the sound outlet 6254, and the rapid vibration of the tamping machine is used to drive the sound absorption while being transmitted. The casing 6255 slides up and down, and seals the sound hole 6254 when sliding, and uses the sealing e...

Embodiment 3

[0053] Such as Figure 1-9 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, a buffer spring 33 is fixedly connected to the inner surface of the support column 31, and a hole 34 is provided on the outer surface of the support column 31, and the buffer spring The outer surface of 33 is lapped with a push rod 35, the outer surface of the push rod 35 is fixedly connected with a rotating ring 36, the outer surface of the rotating ring 36 is movably connected with an externally inserted cone 37, and the inner wall of the support column 31 is fixedly connected with a Connection plate 38 .

[0054] In this embodiment, the push rod 35 is used to press down, and the triangular cone 32 is inserted into the soil. When pressing down, the externally inserted cone 37 is in contact with the surface of the connecting plate 38, and the surface of one end of the externally inserted cone 37 is used to The inclined plate on the top slides on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com