Lifting type waterway structure

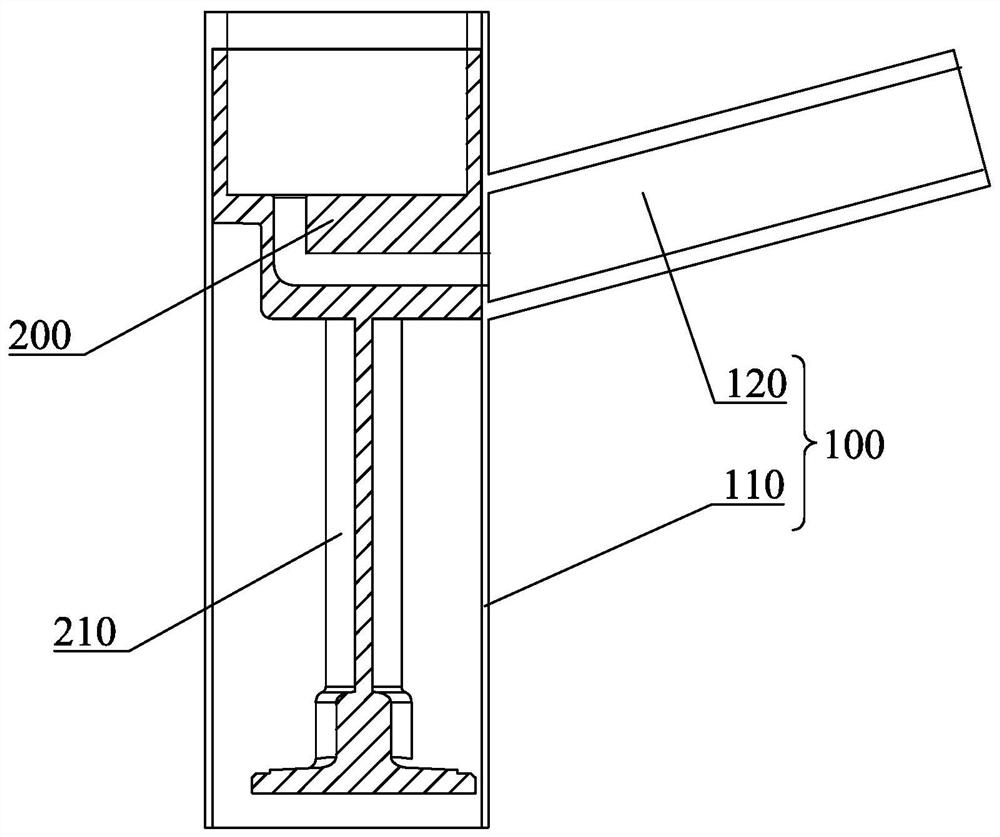

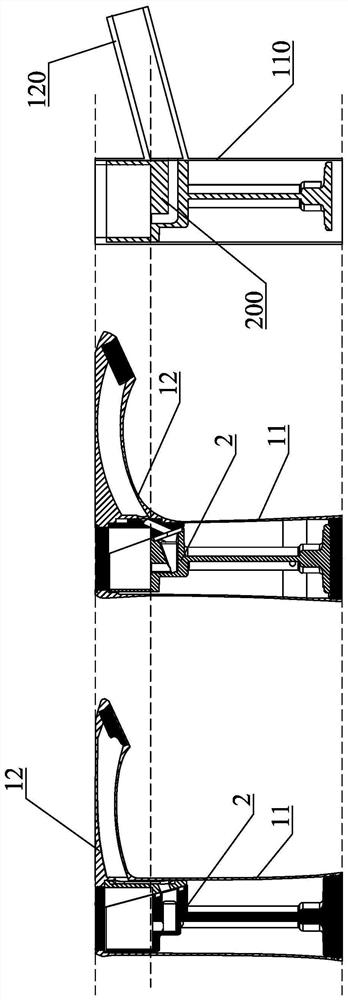

A waterway structure and lifting technology, which is applied in the field of faucets, can solve the problems of lowering the grade of faucets and user experience, space restrictions, and complicated processes, etc., and achieve the effect of flexible shape design, tightness, and guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

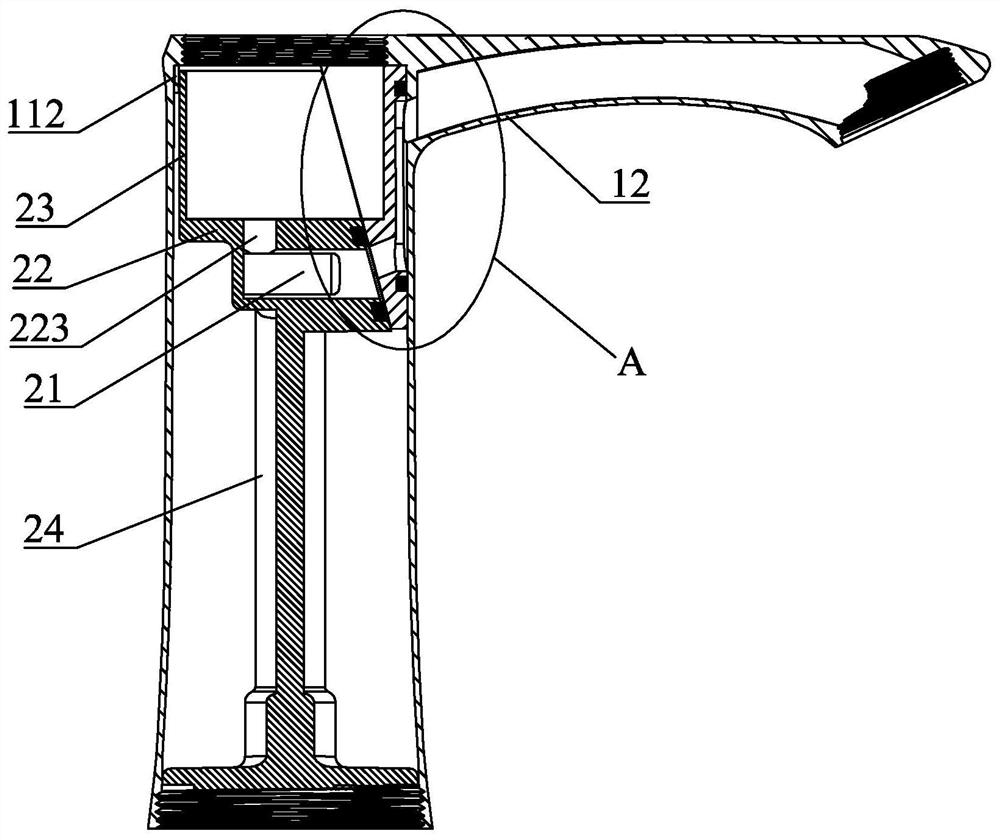

[0062] Preferably, as the second embodiment of the present invention, a limiting protrusion 33 is provided on the surface of the waterway lifting piece 3 abutting against the shell main body 11, and the water outlet end 312 of the lifting channel 31 is set at the limiting position. On the protrusion 33 ; on the inner wall of the housing body 11 is formed a limiting groove 116 that cooperates with the limiting protrusion 33 , and the limiting protrusion 33 is embedded in the limiting groove 116 . The waterway lifting piece 3 is preliminarily connected to the inner wall of the housing main body 11 through the limiting protrusion 33 , which facilitates the subsequent sealing connection between the valve core seat 2 and the waterway lifting piece 3 .

[0063] Compared with the second embodiment of the waterway lifting piece 3, the first embodiment of the waterway lifting piece 3 has the characteristics of convenient processing and low requirements on processing accuracy.

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com