Refrigerant cooling system and method for frequency converter

A cooling system and frequency converter technology, applied in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of reducing the service life of valves, frequent valve movements, increasing thermal shock stress of heating elements, etc. Low, improve the effect of lower valve service life and precise control of the number of actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

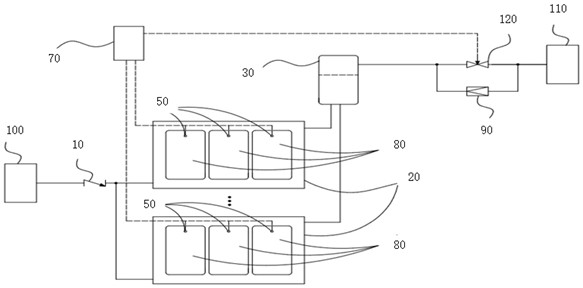

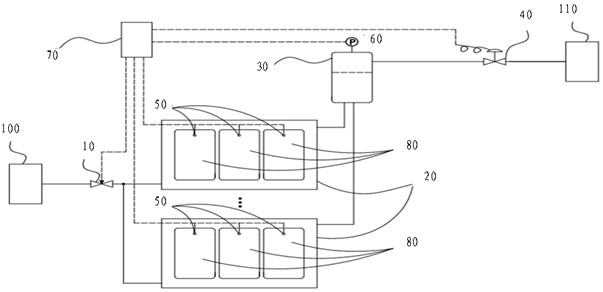

[0026] According to an embodiment of the present invention, an embodiment of a refrigerant cooling system for a frequency converter is provided, figure 1 It is a schematic diagram of a refrigerant cooling system of a frequency converter according to an embodiment of the present invention, such as figure 1 As shown, the system includes: an inlet valve 10, a heat dissipation cold plate 20, a liquid storage tank 30, an outlet valve 40, a temperature sensor 50, a pressure sensor 60 and a controller 70, wherein the controller is connected to the inlet valve, the The outlet valve, the temperature sensor and the pressure sensor are connected, the heat dissipation cold plate is arranged on the heating unit 80 of the frequency converter, and is respectively connected with the inlet valve and the liquid storage tank, and the The liquid storage tank is connected with the outlet valve;

[0027] The temperature sensor 50 is used to collect the current temperature of the heat dissipation c...

Embodiment 2

[0059] The embodiment of the present invention also provides a method for cooling a frequency converter with a refrigerant. The above-mentioned frequency converter for cooling the refrigerant is used to implement the method for cooling the frequency converter provided by the embodiment of the present invention. The following is the frequency converter provided by the embodiment of the present invention The specific introduction of the refrigerant cooling method.

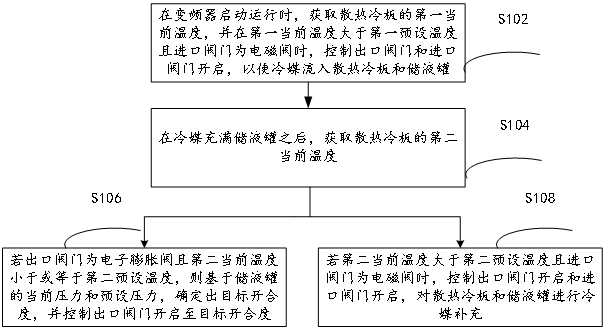

[0060] Such as image 3 as shown, image 3 It is a flowchart of the refrigerant cooling method of the above-mentioned frequency converter, and the refrigerant cooling method of the frequency converter includes:

[0061] Step S102, when the frequency converter starts running, obtain the first current temperature of the cooling plate, and when the first current temperature is greater than the first preset temperature and the inlet valve is a solenoid valve, control the outlet valve and the The inlet valve is opened s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com