A Hall sensor temperature compensation circuit and its compensation method

A technology of temperature compensation circuit and Hall sensor, which is applied in the field of sensors, can solve problems such as unsuitable compensation and calibration, and achieve the effects of fast response speed, low process dependence and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

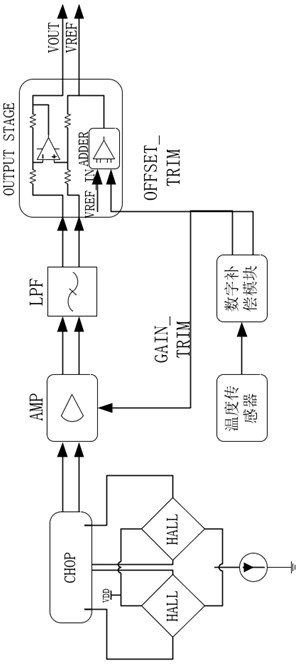

[0042] Such as Figure 1 to Figure 3 As shown, the present invention provides a Hall sensor temperature compensation circuit, including:

[0043] Hall sensor module, which generates analog voltage signal according to external magnetic field and current;

[0044] The analog compensation module is connected with the Hall sensing module, and is used for analog compensation to the generated analog voltage signal;

[0045] The temperature sensor module is used to obtain the current external environment temperature information;

[0046] An output module, configured to convert the analog voltage signal after analog compensation to output a digital voltage signal;

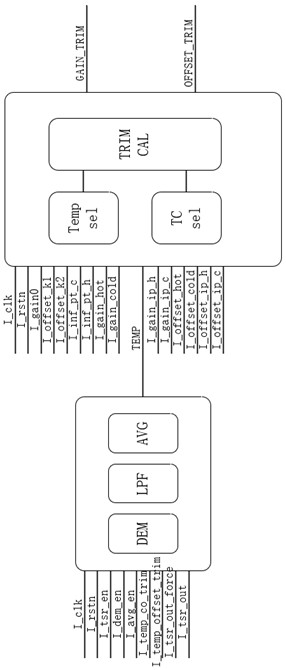

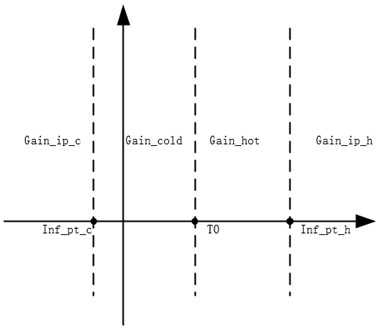

[0047] A digital compensation module, which includes a compensation calculation unit, the compensation calculation unit generates a corresponding compensation codeword according to the external environment temperature information, and the compensation codeword includes a gain codeword and a drift codeword, and then the g...

Embodiment 2

[0076] The present invention also provides a Hall sensor temperature compensation control method. According to the compensation circuit according to the first embodiment, the external temperature is measured and the Hall sensor is temperature compensated.

[0077] It should be noted that, in the present invention, descriptions involving "first", "second", "one" and so on are only for descriptive purposes, and should not be understood as indicating or implying their relative importance or implicitly indicating The number of technical characteristics. Thus, the features defined as "first" and "second" may explicitly or implicitly include at least one of these features. In the description of the present invention, "plurality" means at least two, such as two, three, etc., unless otherwise specifically defined. The terms "connection" and "fixation" should be interpreted in a broad sense, for example, "fixation" can be a fixed connection, a detachable connection, or an integral bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com