Digital modeling and intelligent detection system for power secondary equipment

A technology of intelligent detection and secondary equipment, applied in the direction of design optimization/simulation, etc., can solve the problem of lack of effective integration and feedback of product definition, and achieve the effect of making up for defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

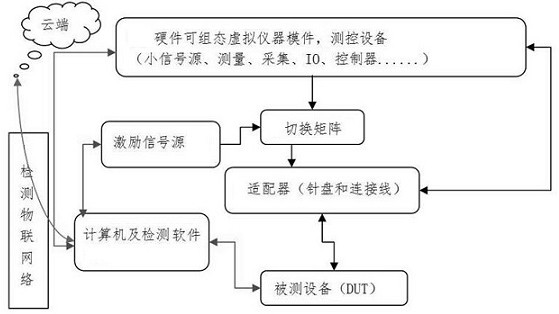

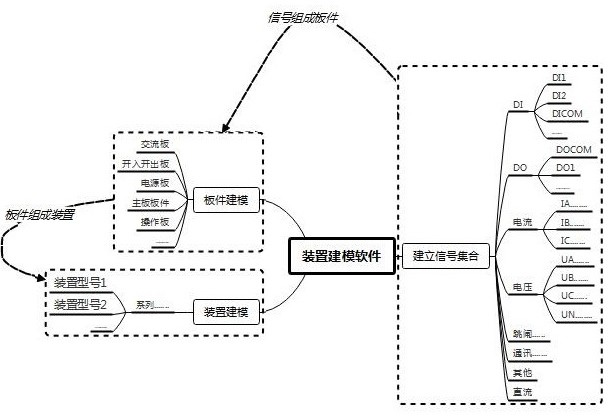

[0030] The invention provides a digital modeling and intelligent detection system for electric secondary equipment, which applies the idea of digital main line to the intelligent production and detection process of electric power system secondary equipment manufacturers, and models the digital secondary equipment from the bottom layer with the same syntax and semantics. The model has the same data source, so the digital model has a standard development description, which can be transmitted step by step without distortion and can be traced back. The digital thread is an approach that creates unified access to data with a single source of truth. When used across the enterprise, this approach enables consistency and enhances collaboration by mapping a solid set of data to different functions. After the data set is enabled, the data can be synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com