Production process for avoiding reverse lamination of battery cell laminations

A production process and lamination technology, which is applied in the field of production process to avoid reverse stacking of cell stacks, can solve problems such as the inability of employees to identify with the naked eye, the number of layers of cell stacks, and major problems, so as to avoid cell burning/short circuit. , The effect of improving product safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

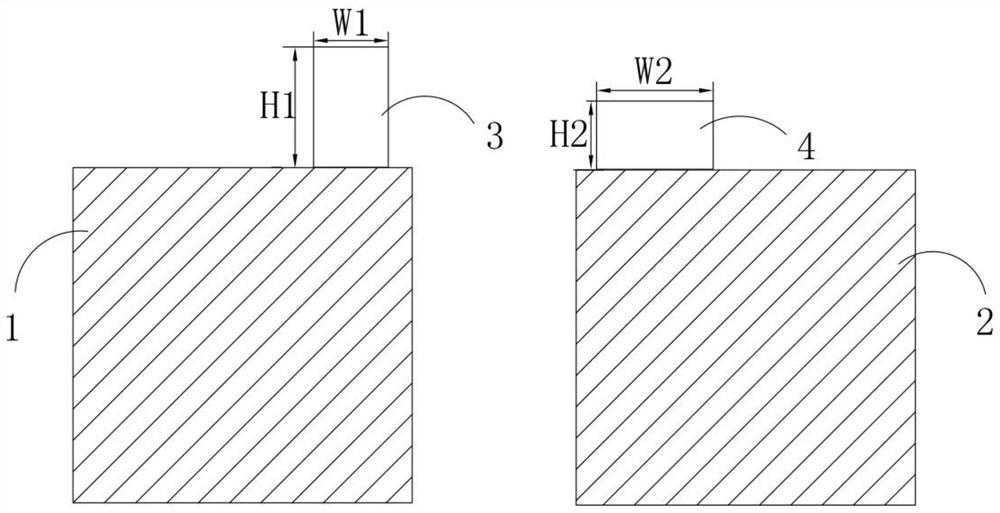

[0036] The embodiment of the present application provides a production process that avoids the reverse stacking of cell stacks, and solves the problem of reverse stacking / duplication of stacks in the prior art due to manual feeding and stacking / equipment failures. , due to the same width / height of positive and negative pole pieces, too many layers of stacked cells, employees cannot visually identify defective products, and defective products are easy to flow out, resulting in combustion after the cells are formed and charged, resulting in major safety accidents technical problem.

[0037] The technical solution in the embodiment of the present application is to solve the above-mentioned crosstalk problem, and the general idea is as follows:

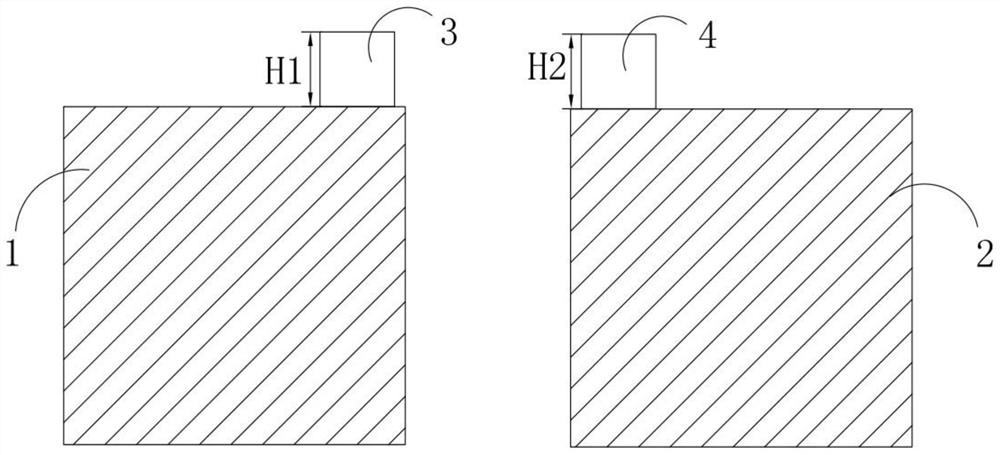

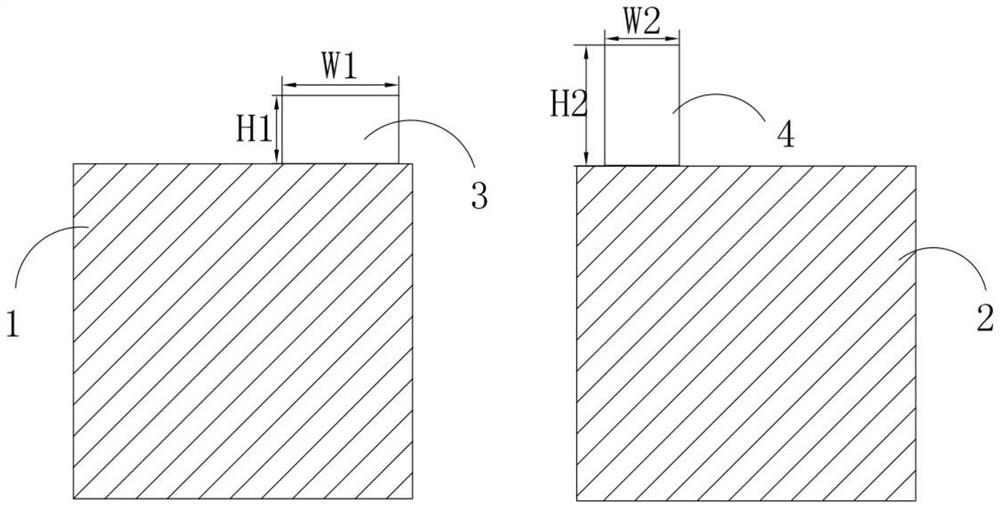

[0038] Step 1), the positive electrode sheet and the negative electrode sheet are respectively cut once to obtain a positive electrode sheet with a positive electrode welding blank area and a negative electrode sheet with a negative elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com