Fire safety system for petrochemical plant

A security system and chemical plant technology, applied in the field of intelligent fire protection in petroleum and petrochemical plants, can solve problems such as safety discounts, too late to alarm, and dangers, and achieve the effects of improving safety, protecting fires, and preventing fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

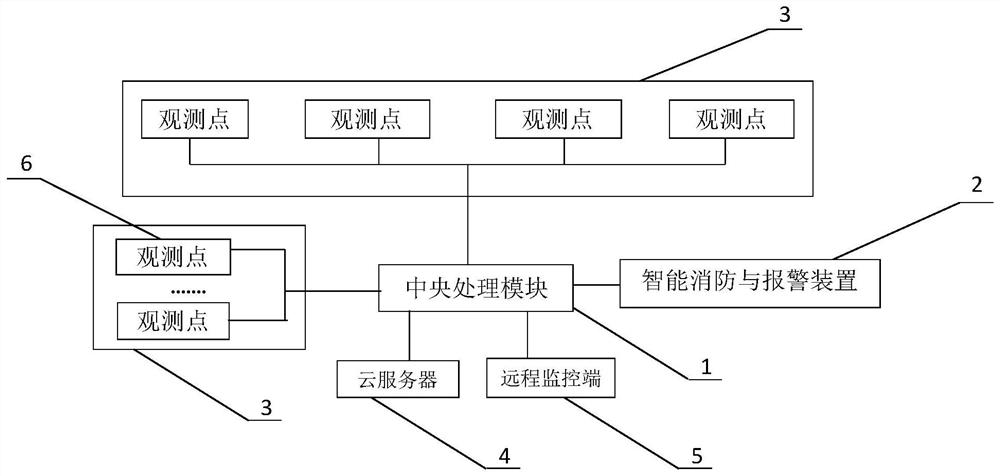

[0052] see Figure 1-4 , the present invention provides a technical solution:

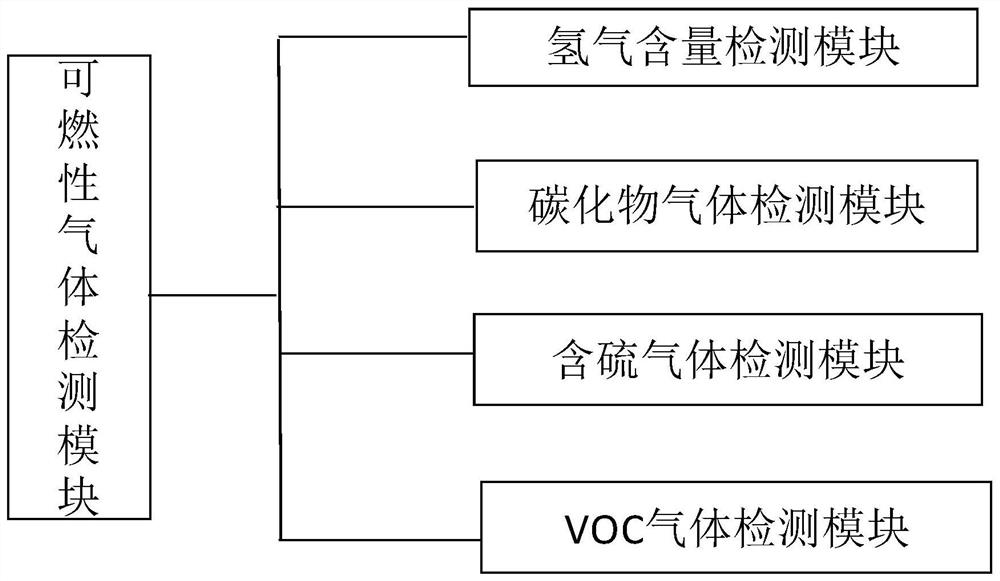

[0053] A fire safety system for petrochemical plants, including a central processing module 1, an intelligent fire protection and alarm device 2, an observation point group 3, a cloud server 4, and a remote monitoring terminal 5, wherein the central processing module 1 and the The intelligent fire-fighting and alarm device 2, the observation point group 3, the cloud server 4 and the remote monitoring terminal 5 are connected by network communication; the observation point group 3 includes a plurality of observation points 6, each of the observation points 6. A combustible gas detection module group 7 and a temperature detection module group 8 are provided; thus the central processing module 1 is respectively connected to all the combustible gas detection module groups 7 and the temperature detection module group 8 through network communication;

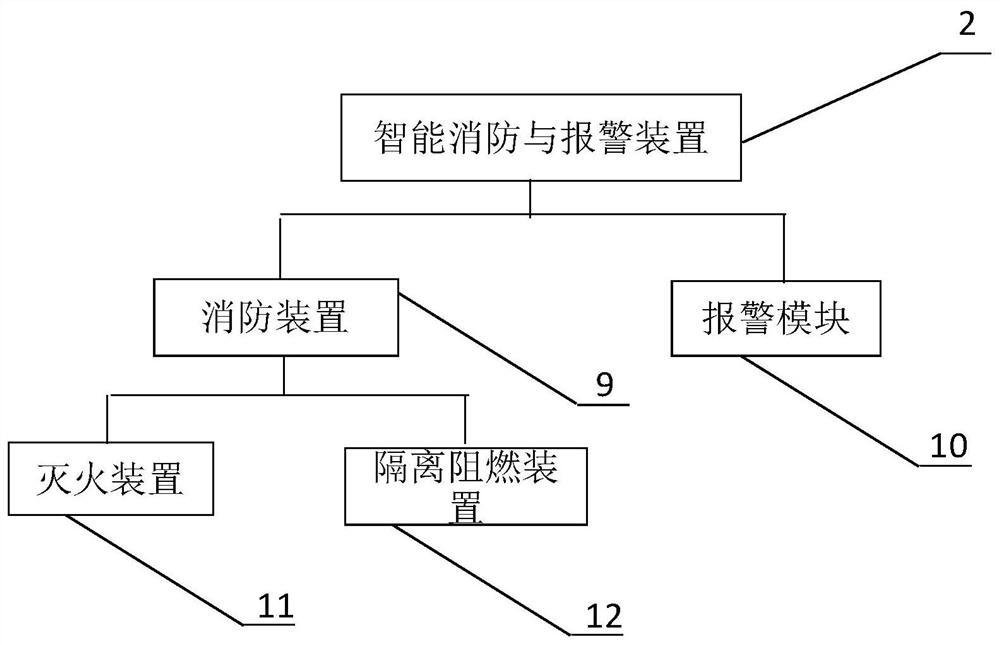

[0054] The intelligent fire-fighting and alarm devi...

Embodiment 2

[0068] A fire safety intelligence system for petrochemical plants, including a central processing module, an intelligent fire protection and alarm device, a combustible gas detection module group, a temperature detection module group, an observation point group, a cloud server, and a remote monitoring terminal. The output end of the central processing module is electrically connected to the input end of the intelligent fire protection and alarm device, and the intelligent fire protection and alarm device includes a fire fighting device and an alarm module, wherein the fire fighting device includes a fire extinguishing device and an isolation flame retardant device for In the event of a fire, it can be dealt with in time to prevent the fire from spreading. The output end of the central processing module is connected to the cloud server and the input end of the remote monitoring end by telecommunication in real time. The input end of the central processing module is electrically...

specific Embodiment 3

[0070] A fire safety supervision method for a petrochemical plant, using a fire safety system for a petrochemical plant, characterized in that the fire safety supervision method specifically includes the following steps:

[0071] S1: Site selection of the observation point group, wherein, the site selection of the observation point group uses places prone to flammable gas leakage or high-temperature places prone to fire as observation points, and flammable gas is set at the above-mentioned observation points Detection module group 3, temperature detection module group 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com