Waveguide slot antenna plate conveying device

A technology of waveguide crack antenna and conveying device, which is applied in the direction of grinding driving device, grinding slide plate, grinding machine tool parts, etc., can solve the problems that the antenna plate cannot be guaranteed to have the same polishing accuracy and low production efficiency, and achieve improved stability , Improve production efficiency, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0036] Specific embodiments described as follows:

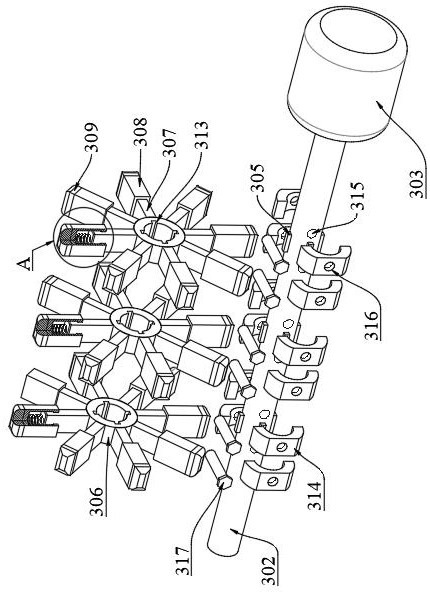

[0037] First select the antenna sheet sizes adapted according to the belt 105, so that projection 106 may be stuck in the belt 105, then block 306 is connected through the second shaft 302 is provided, and the second shaft pin 302 of the key 305 and the connecting block 306 with the keyways 313, and the connecting block 306 disposed on each side of two limiting blocks 314 and 317 are connected with the two stopper pin 314, the connecting block 306 is fixed;

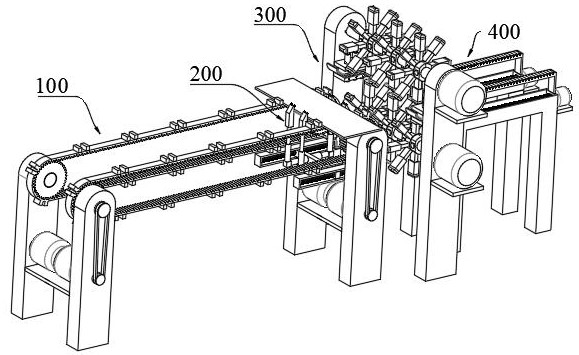

[0038] After the antenna plate is placed in a set of protrusions 106, to start the first motor 104, first drive shaft 103 rotates, following the rotation of the gear 102 connected to a first shaft 103, is rotated to follow the conveyor belt 105, the conveyance of the sheet antenna, antenna when the sheet conveying end of the conveyor 105 to start a first telescopic rod 206, drive block 207 is moved upward clip, clamp block clamp antenna plate 207, clamp plate 207 side surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com