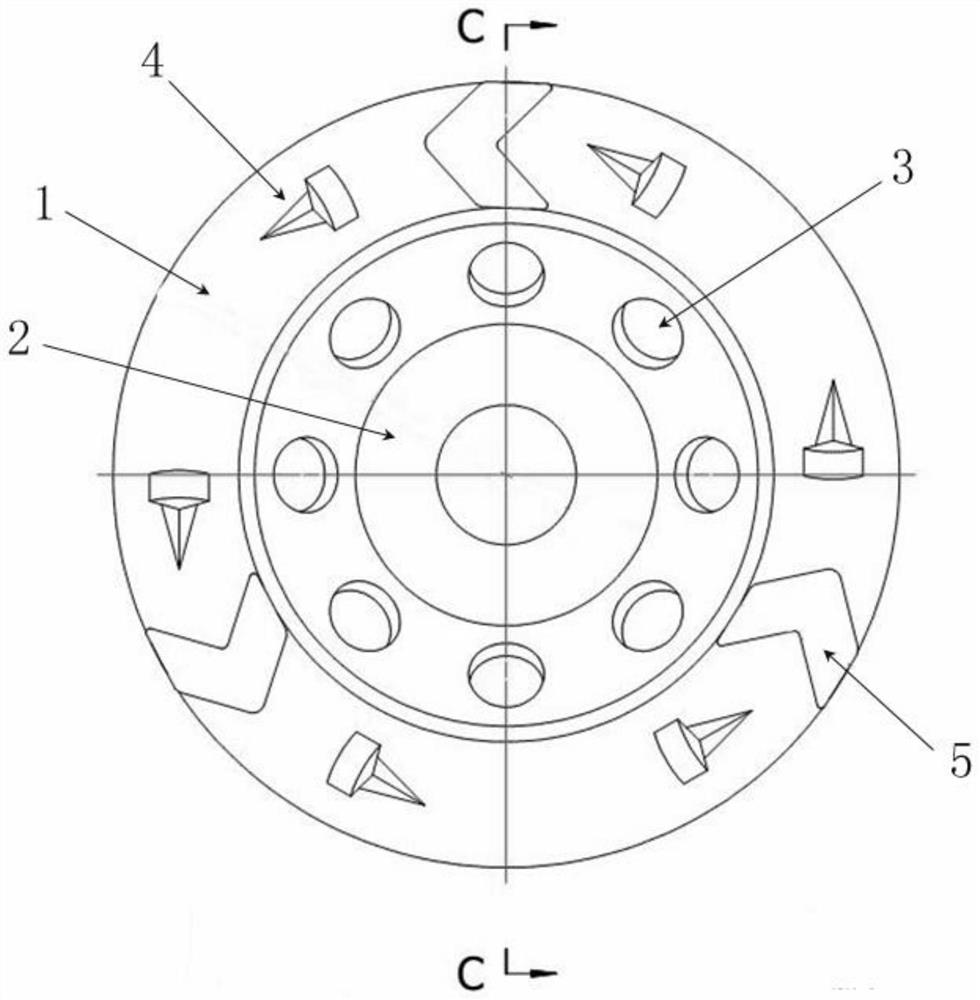

Multifunctional PCD diamond grinding wheel and preparation method thereof

A diamond and multi-functional technology, applied in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve problems such as easy blockage and heat dissipation, and achieve good support and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

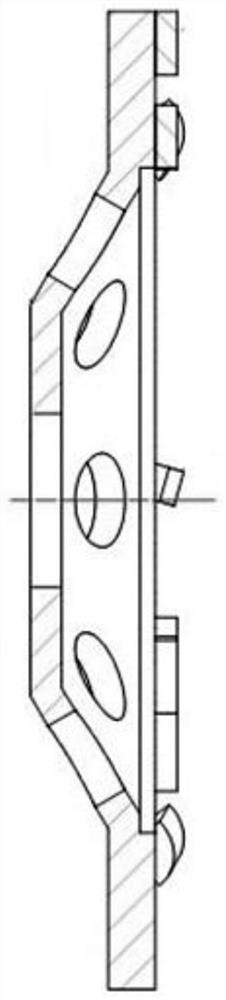

[0037] The preparation method of described multifunctional PCD diamond grinding wheel, comprises the steps:

[0038] (1) prepare the disc-shaped substrate, and offer a groove for partially embedding the PCD abrasive block on the substrate at a position corresponding to the PCD abrasive block;

[0039] (2) Prepare PCD grinding block and diamond cutter head;

[0040] (3) The PCD grinding block is high-frequency welded in the groove of the disc-shaped substrate by using the silver soldering sheet; the diamond cutter head is welded on the substrate by high-frequency using the silver soldering sheet.

Embodiment 1

[0042] The composition of the raw material of the present embodiment diamond cutter head is as follows in parts by weight:

[0043] 30 parts of copper, 39 parts of iron, 10 parts of nickel, 14.5 parts of cobalt, 10 parts of tin, 1.5 parts of phosphorus or carbon, 1.1 parts of liquid paraffin, 1.4 parts of diamond; diamond particle size 40 / 45, compressive strength 25kg.

[0044] The multifunctional PCD diamond grinding wheel manufacturing process of the present embodiment is as follows:

[0045] 1. Substrate processing

[0046] According to the requirements of the drawing, turn and cut the required substrate, and open a groove on the substrate corresponding to the position of the PCD abrasive block for partially embedding the PCD abrasive block;

[0047] 2. Sintering molding of diamond blades:

[0048] Copper, iron, nickel, cobalt, tin, phosphorus or carbon, liquid paraffin and diamond are mixed together, then formed by cold pressing, sintered by hot pressing, and polished by g...

Embodiment 2

[0054] The composition of the raw material of the present embodiment diamond cutter head is as follows in parts by weight:

[0055] 32 parts of copper, 35 parts of iron, 8 parts of nickel, 16 parts of cobalt, 9 parts of tin, 1.5 parts of phosphorus or carbon, 1.1 parts of liquid paraffin, 1.2 parts of diamond; diamond particle size 40 / 45, compressive strength 25kg.

[0056] The multifunctional PCD diamond grinding wheel manufacturing process of the present embodiment is as follows:

[0057] 1. Substrate processing

[0058] According to the requirements of the drawing, turn and cut the required substrate, and open a groove on the substrate corresponding to the position of the PCD abrasive block for partially embedding the PCD abrasive block;

[0059] 2. Sintering molding of diamond blades:

[0060] Copper, iron, nickel, cobalt, tin, phosphorus or carbon, liquid paraffin and diamond are mixed together, then formed by cold pressing, sintered by hot pressing, and polished by gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com