Method for hydraulically lifting and hoisting urea synthesis tower

A technology of hydraulic lift and hydraulic lifter, which is applied to the braking device of lifting equipment, hoisting device, transportation and packaging, etc. It can solve the problems of large construction space, unsuitable equipment for hoisting, low safety and reliability, etc., and achieves The effect of operating process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

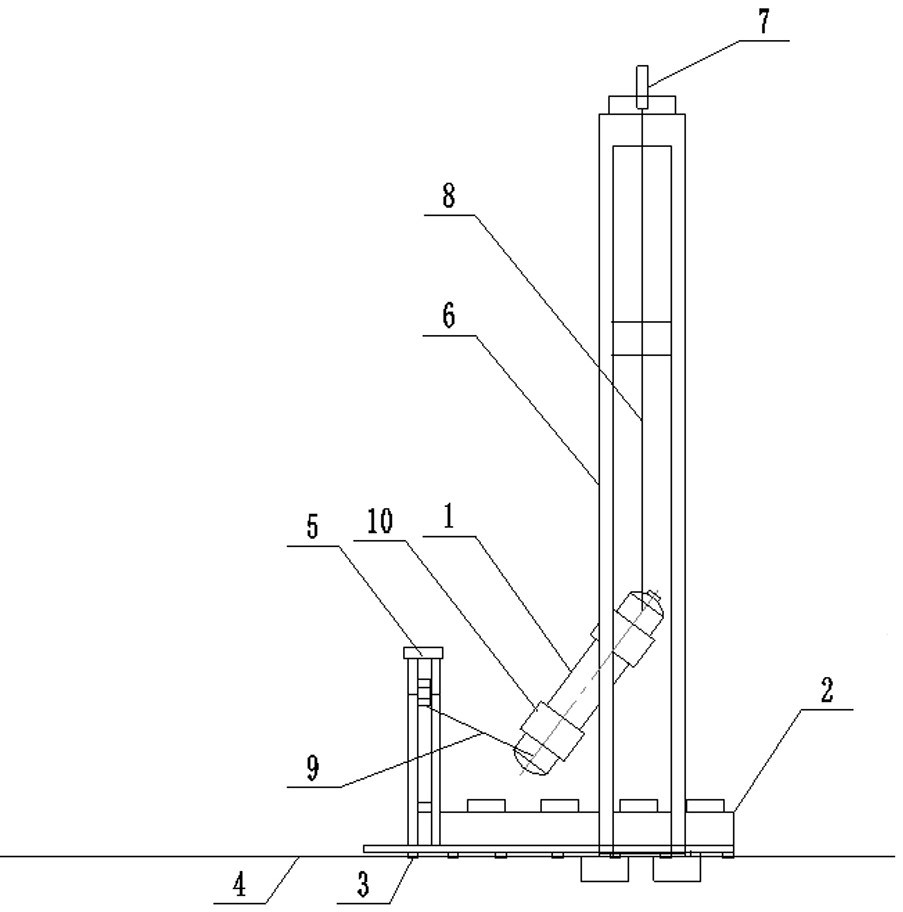

[0028] Based on the problem that the current method of hydraulically lifting and hoisting a urea synthesis tower occupies a very large construction space, a typical embodiment of the present invention provides a method for hydraulically lifting and hoisting a urea synthesis tower, including the following steps.

[0029] Step 1, a hydraulic lifter 7 is set on the top of the structural frame 6;

[0030] Step 2, setting the track 4 on the ground at the bottom of the structural frame 6, and installing a mobile support platform on the track 4;

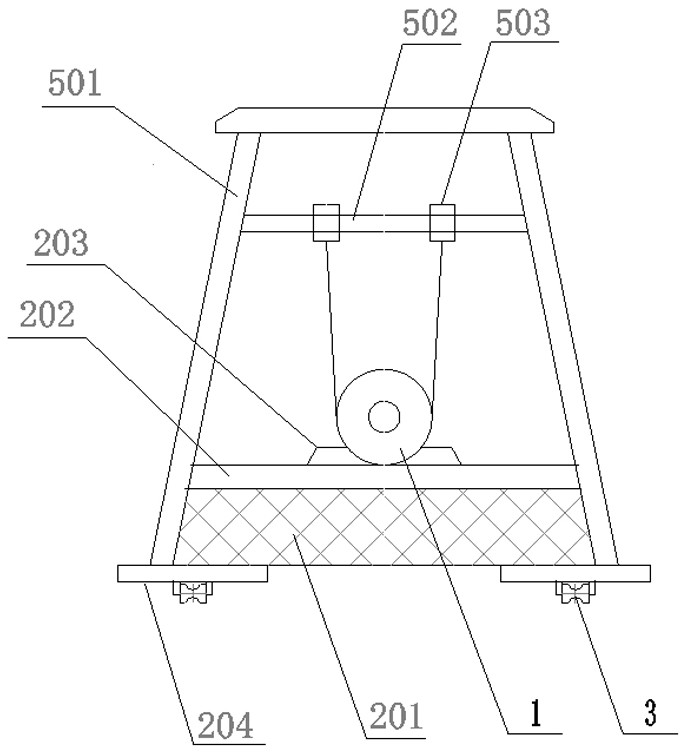

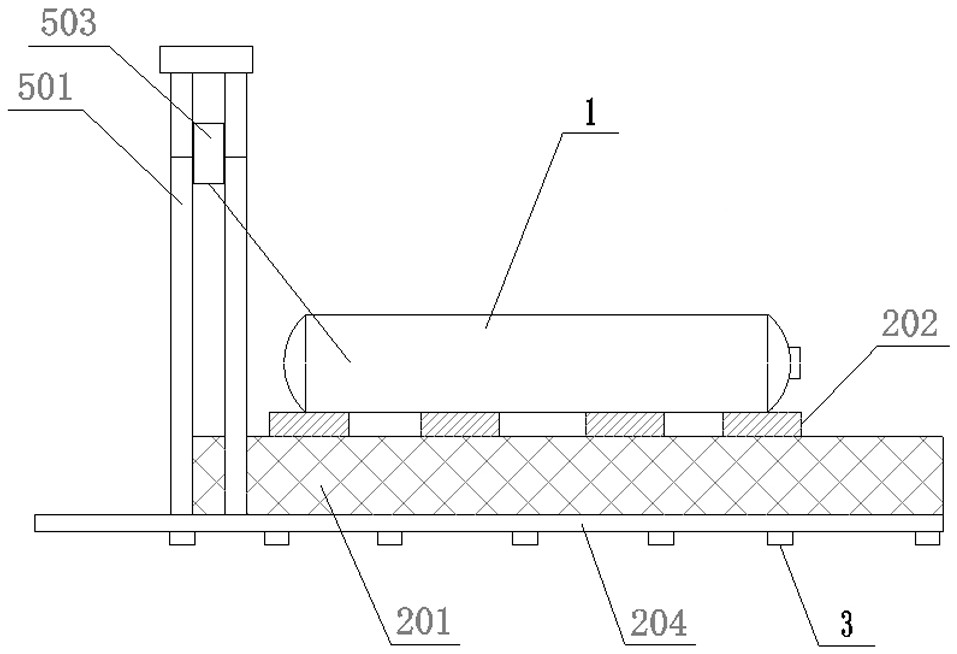

[0031] Such as figure 1 , figure 2 As shown, the mobile support platform includes a frame platform 2, the bottom of the frame platform 2 is provided with a pulley 3, and the pulley 3 cooperates with the track 4 laid on the ground at the bottom of the structural frame; one end of the frame platform 2 is fixedly arranged There are gantry cranes 5;

[0032] Step 3, placing the urea synthesis tower 1 horizontally on the frame platform 2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com