Treatment system for dewatering and fixing of sludge

A treatment system and sludge technology, applied in the direction of fixed/solidified sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of large space occupation, inconvenient handling and transfer, broken into pieces, and even Problems such as debris, to achieve the effect of novel structure, convenient transfer and handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

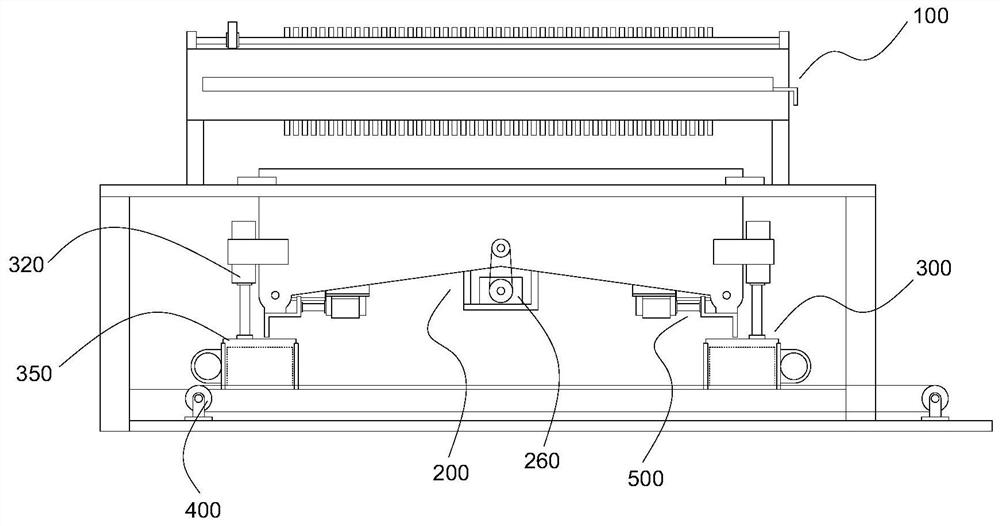

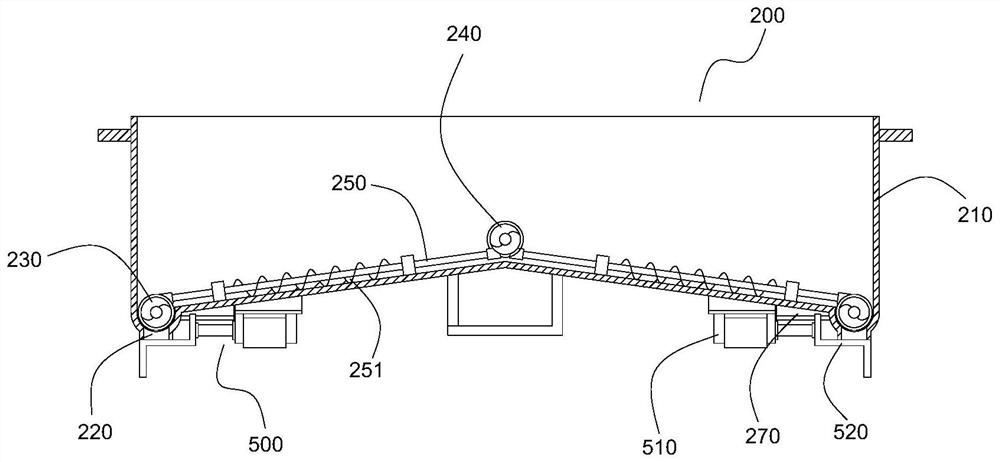

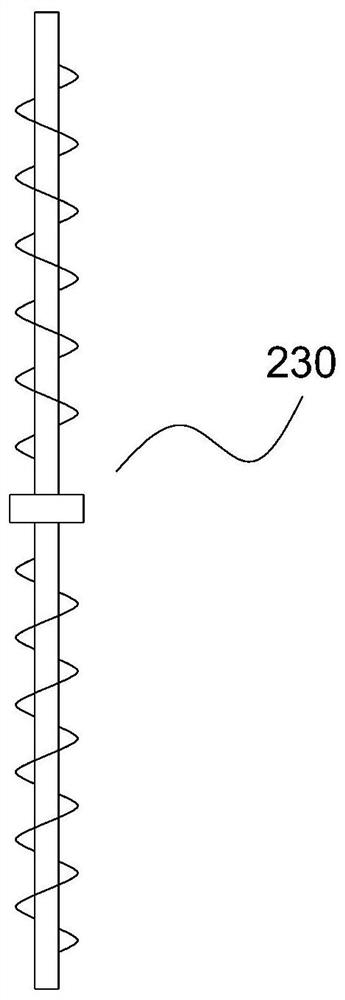

[0025] Such as figure 1 As shown, a specific embodiment of the present invention discloses a sludge dehydration fixed treatment system, including a frame, a dewatering plate frame machine 100 installed on the frame, and a breaking device is provided below the dewatering plate frame machine 100 200, an extruding device 300 is provided below the outlet of the dispersing device 200, and a conveyor belt 400 is provided outside the outlet of the extruding device 300; The falling filter residue is broken up and sent to the extrusion molding device 300; the extrusion molding device 300 squeezes the falling filter residue into a block structure of uniform specifications, and pushes the filter residue block to the conveyor belt 400 for transport.

[0026] The above-mentioned fixed treatment system for slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com