Prefabricated assembly type steel-concrete mixed cantilever structure system for widening road and construction method

A technology of prefabricated assembly and prefabricated components, which is applied to roads, roads, pavements paved with prefabricated blocks, etc., can solve the problems of high cost of anti-overturning, heavy prefabricated beam transportation, long construction period, etc., and achieve the convenience of factory standardized production , Reliable force, guaranteed standardization and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

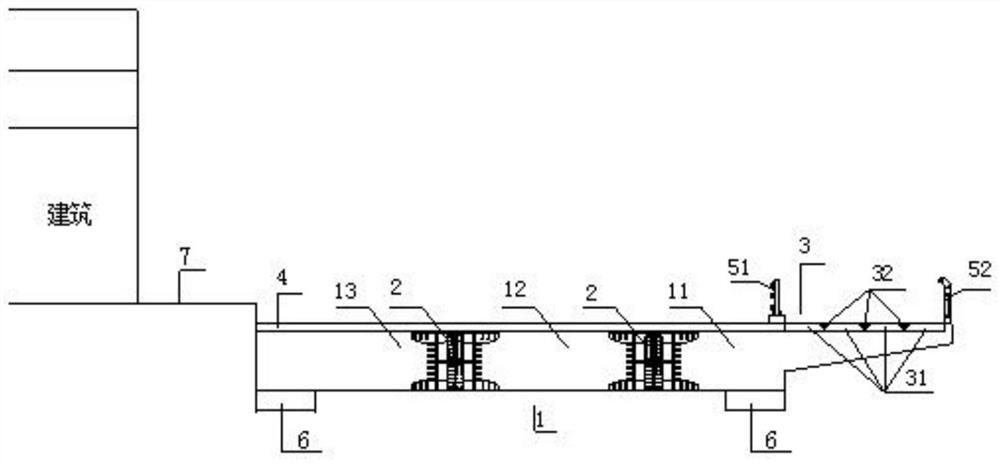

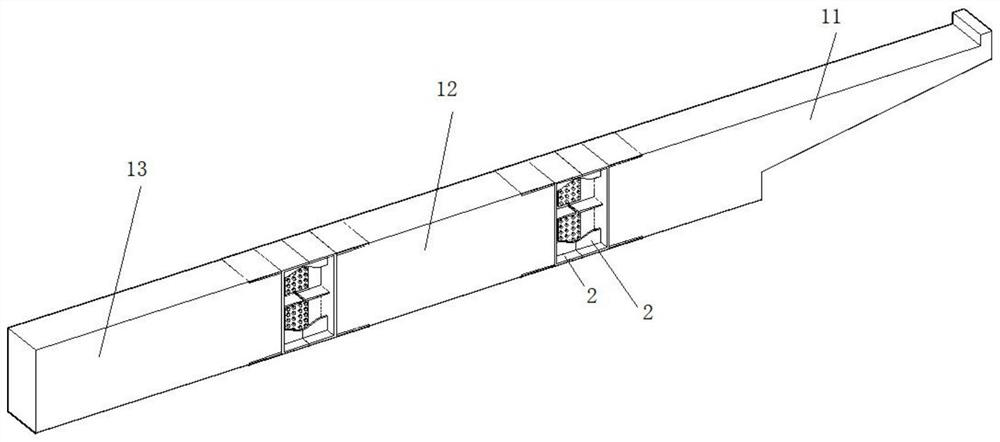

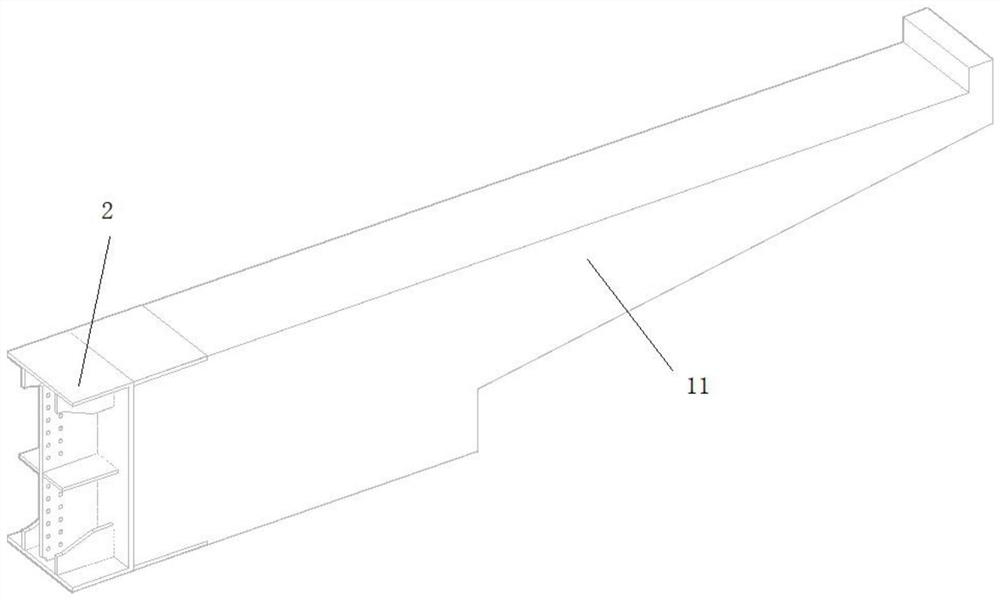

[0038] Referring to the accompanying drawings, it can be seen that the prefabricated assembled steel-concrete hybrid cantilevered structure system for widening the road includes a cantilevered beam 1, and the cantilevered beam 1 includes a first section of concrete prefabricated block 11, a third section of concrete prefabricated block 13, and a cantilevered beam 1. A second section of concrete precast block 12 between a section of concrete precast block 11 and a third section of concrete precast block 13, and a plurality of steel component joint devices 2;

[0039] Both ends of the second section of concrete prefabricated block 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com