Manhole door sealing box and tower-type supercritical boiler

A supercritical boiler and sealed box technology, applied in boiler water pipes, steam boilers, steam boiler accessories, etc., can solve problems such as crack failure of water-cooled wall tubes, prevent crack failure problems, ensure normal operation, and increase stress area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

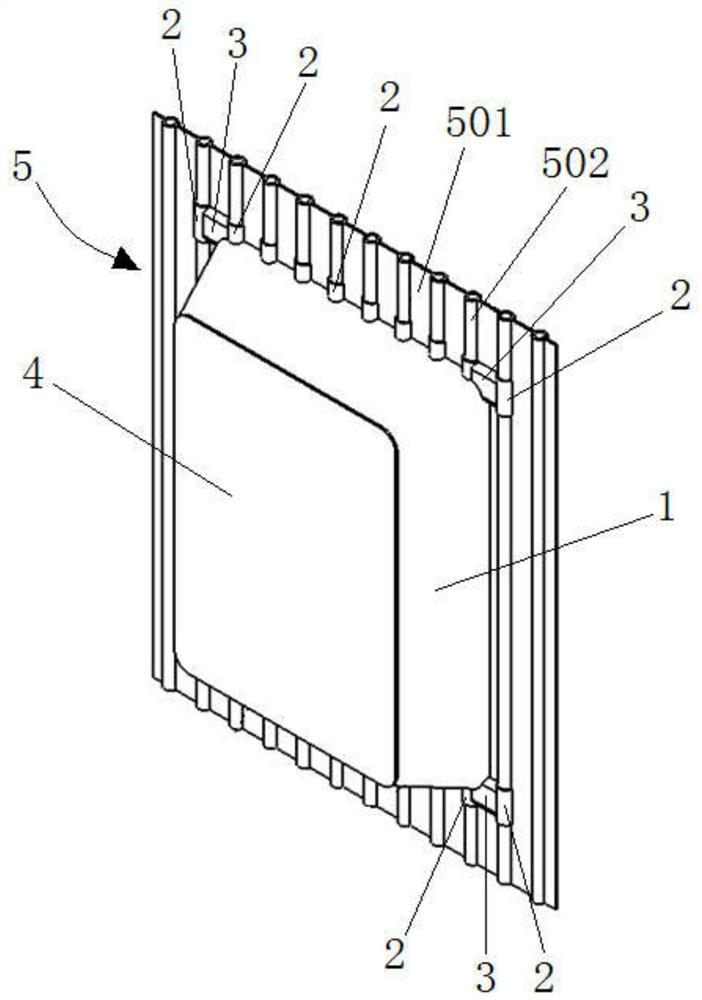

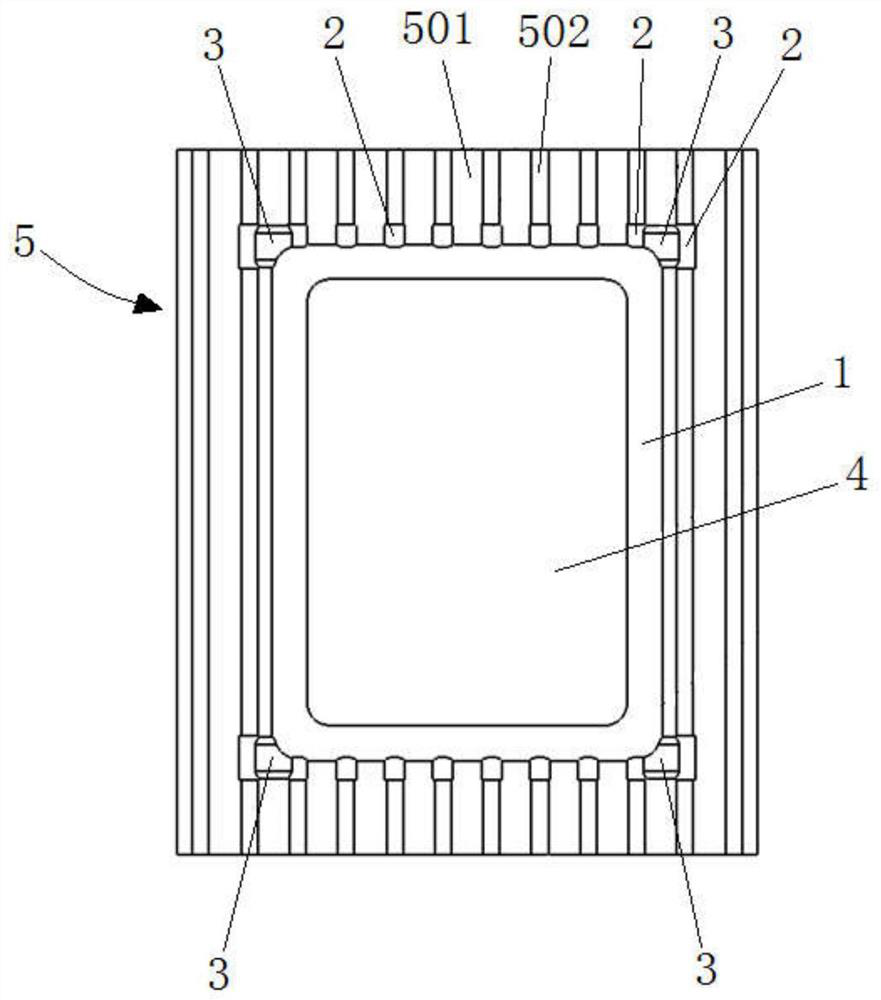

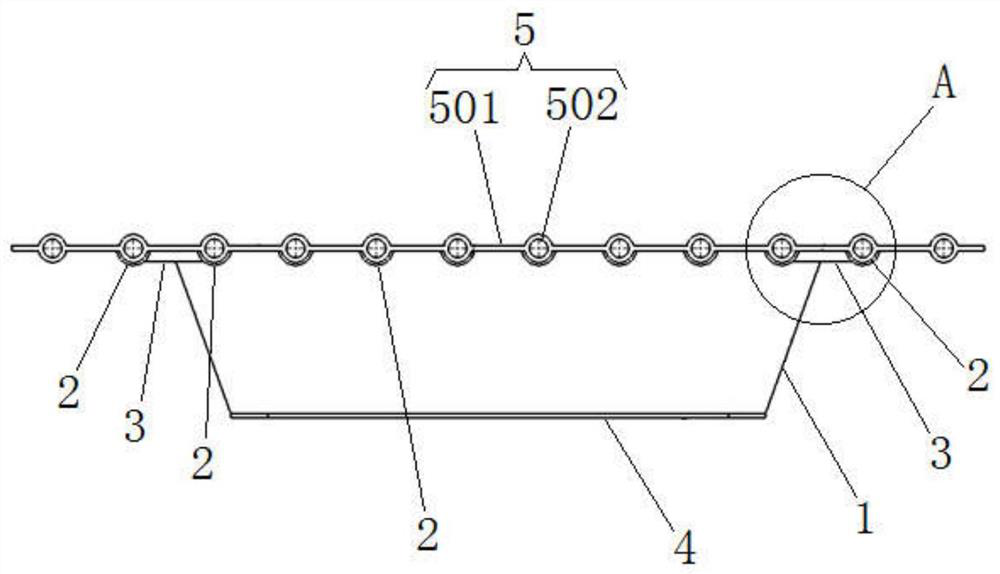

[0033] Such as Figure 1 to Figure 4 As shown, the present invention provides a manhole door sealing box, the manhole door sealing box is sealed and arranged at the manhole outside the water wall 5, and the manhole door sealing box includes a sealing box body 1 and a plurality of protective tiles 2 and a plurality of corner guards 3, wherein: each guard tile 2 is coated on the outside of each water wall tube 502 in the water wall 5, and the two opposite side edges of the guard tile 2 are respectively connected to the fins 501 located on both sides of the water wall tube 502 , and the protection tiles 2 are not directly connected with the water wall pipe 502, and each protection tile 2 is located at a position opposite to the edge of the sealed box body 1; each corner protection 3 is connected between two adjacent protection tiles 2, and the corner protection 3 Also not directly connected with the water-cooled wall pipe 502, each corner protector 3 is located at a position oppo...

Embodiment approach 2

[0048] Such as Figure 1 to Figure 3 As shown, the present invention provides a tower-type supercritical boiler, which includes a water-cooled wall 5 and the above-mentioned manhole door sealing box, and the manhole door sealing box is sealed and arranged at the manhole on the water-cooled wall 5 .

[0049] The characteristics and advantages of the tower supercritical boiler of the present invention are:

[0050] The tower-type supercritical boiler can effectively solve the problem that the water-cooled wall tube 502 on the water-cooled wall 5 is prone to cracks at the joint positions of the top corners of the manhole door sealing box and the upper and lower edges due to stress concentration. The technical problem of failure can effectively improve the stability of the water wall 5 and the safety of the operation of the tower supercritical boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com