Soft package lithium battery cell module assembly structure and assembly method

A soft-pack lithium battery and cell module technology, which is applied to battery pack parts, secondary batteries, structural parts, etc., can solve the problems of poor heat dissipation and low connection firmness, and achieve good heat dissipation and convenience The effect of connection, connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

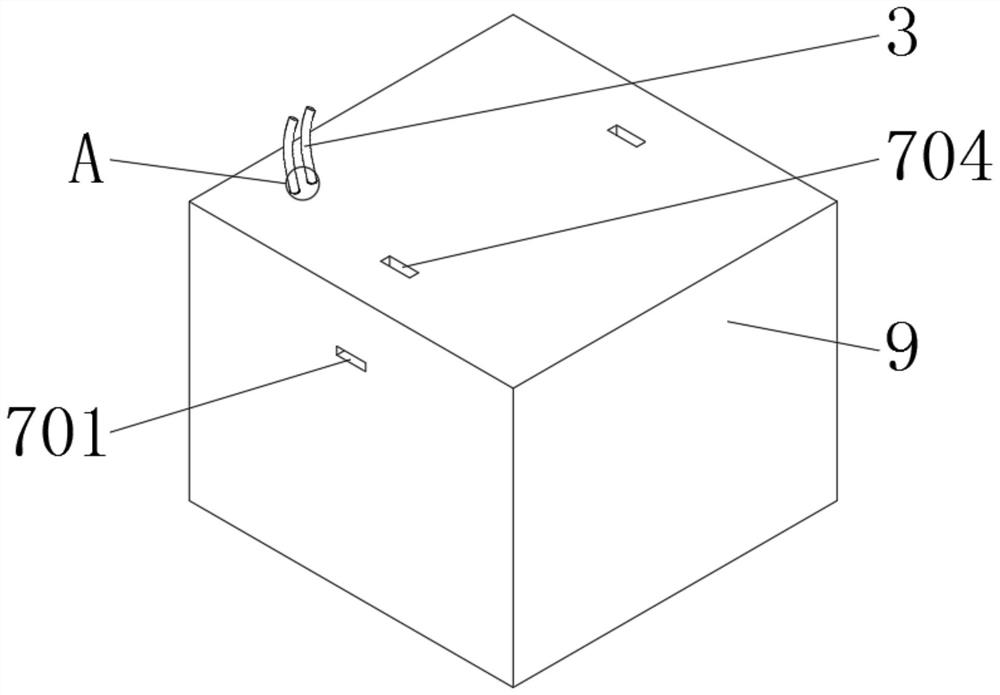

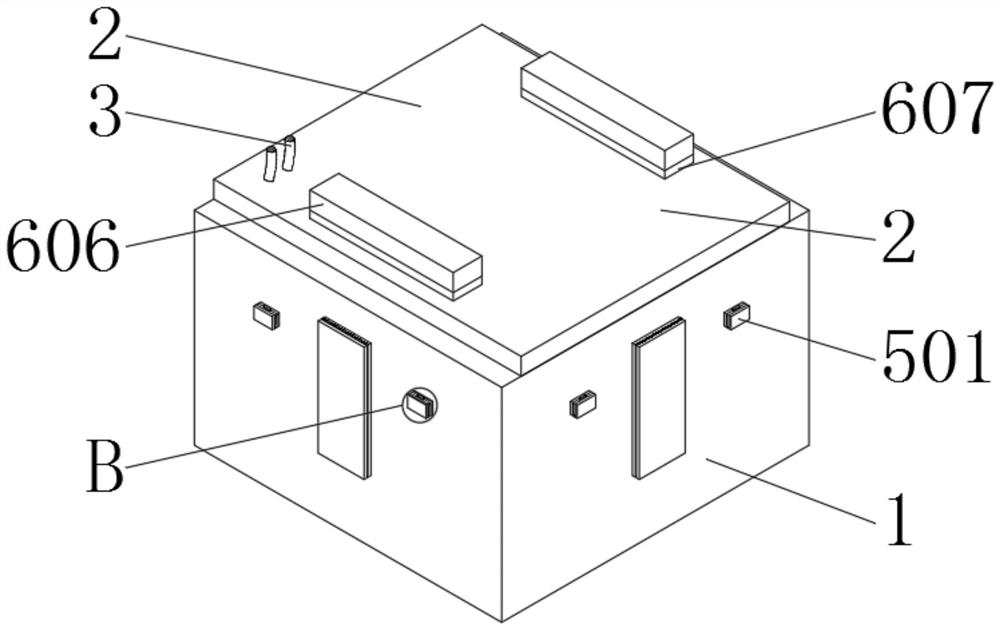

[0041] Such as Figure 1 to Figure 10 As shown, a soft-pack lithium battery cell module assembly structure provided by the present invention includes a cell 1, a control panel 2, a power connection line 3, an insulating plate 4, connecting parts, a shock absorbing part and a heat dissipation part, and the control panel 2 is connected to the top of the battery cell 1 through a wire, the power connection line 3 is connected to the control panel 2 through a wire, the insulating plate 4 is set on the surface of the battery cell 1 and the control panel 2, and the power connection line 3 penetrates to the bottom of the insulating plate 4 At the top, the connecting parts are fixedly connected around the inner wall of the insulating board 4, the shock absorbing parts are fixedly connected around the inner wall of the insulating board 4 and the surface of the battery cell 1, and the heat dissipation parts are set on the top of both sides of the insulating board 4;

[0042]The connectin...

Embodiment 2

[0059] The shock-absorbing component includes a third connecting adhesive layer 601, the third connecting adhesive layer 601 is located between the first connecting adhesive layer 501 and the second connecting adhesive layer 504, the surface of the third connecting adhesive layer 601 is fixedly connected with a backing plate 602, the pad The surface of the board 602 is fixedly connected with a bump 603, the bottom of the inner wall of the insulating board 4 is fixedly connected with a buffer pad 604, the top of the buffer pad 604 is fixedly connected with a corrugated pad 605, and the front side and the rear side of the top of the inner wall of the insulating board 4 are fixedly connected There is a pressing plate 606 , the bottom of the pressing plate 606 is fixedly connected with a fastening pad 607 , and the bottom of the fastening pad 607 is in contact with the top of the control panel 2 .

[0060] The number of the third connecting adhesive layer 601 is eight, the material...

Embodiment 3

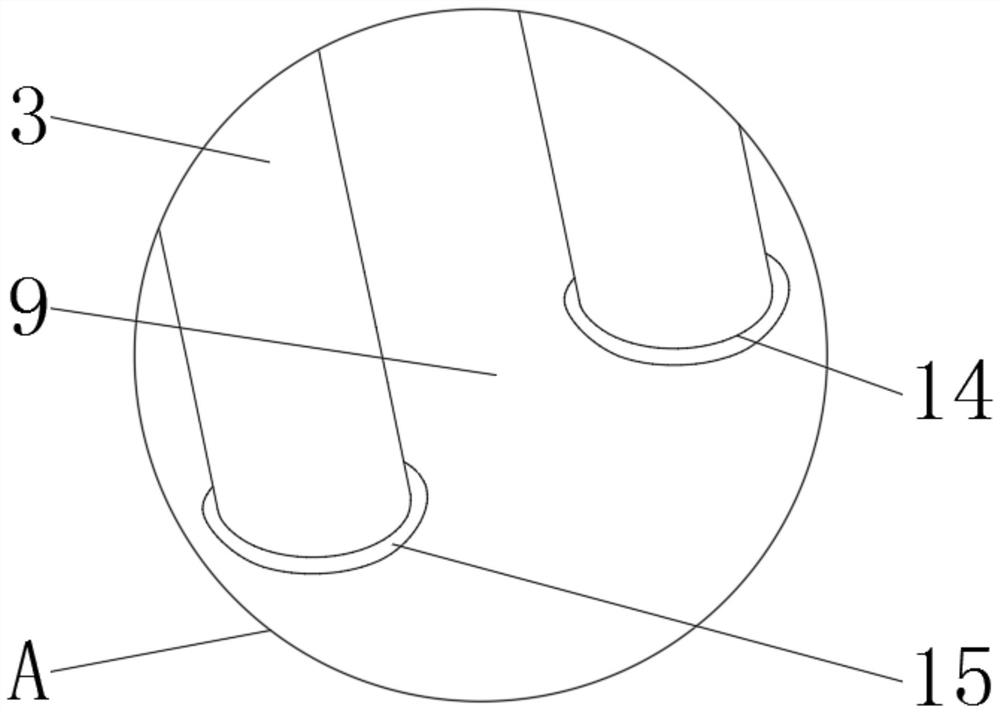

[0064] The heat dissipation components include an air inlet 701, and the tops on both sides of the inner wall of the insulation board 4 are fixedly connected with an arc-shaped plate 702 at the top of the air inlet 701, and both sides of the bottom of the inner wall of the insulation board 4 are fixedly connected with concave blocks for use with the arc-shaped board 702 703 , the top of the arc-shaped plate 702 extends to the inside of the concave block 703 , and the top of the inner wall of the insulating plate 4 is provided with a heat dissipation port 704 .

[0065] The arc-shaped plate 702 is arranged in a semicircle shape, and the inner wall of the concave block 703 is fixedly connected with a filling pad 13 , and the filling pad 13 is in close contact with the arc-shaped plate 702 .

[0066] The present invention can enhance the stability of the arc-shaped plate 702 inside the insulating plate 4 by setting the filling pad 13, avoiding the phenomenon that the arc-shaped pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com