Disc type motor with universal installation structure

An installation structure, the technology of the disc motor, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of poor versatility, the connection structure of the disc motor is not universal, etc., and achieve the effect of preventing breakage and good heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

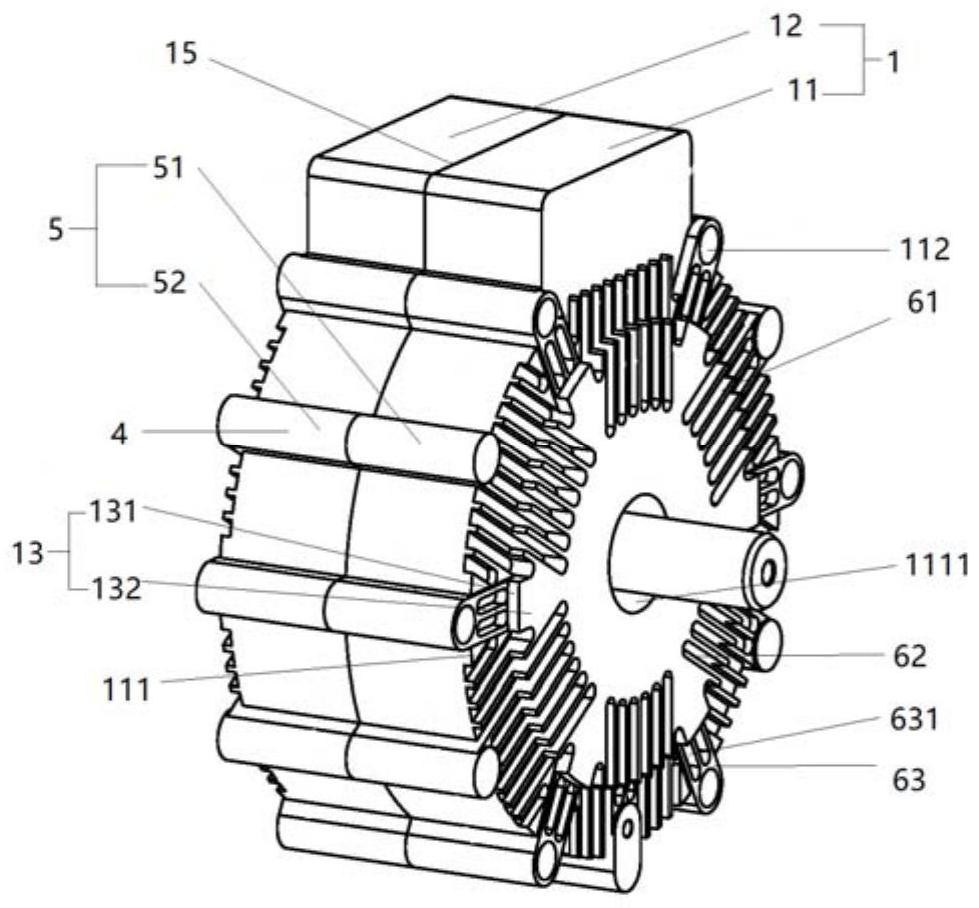

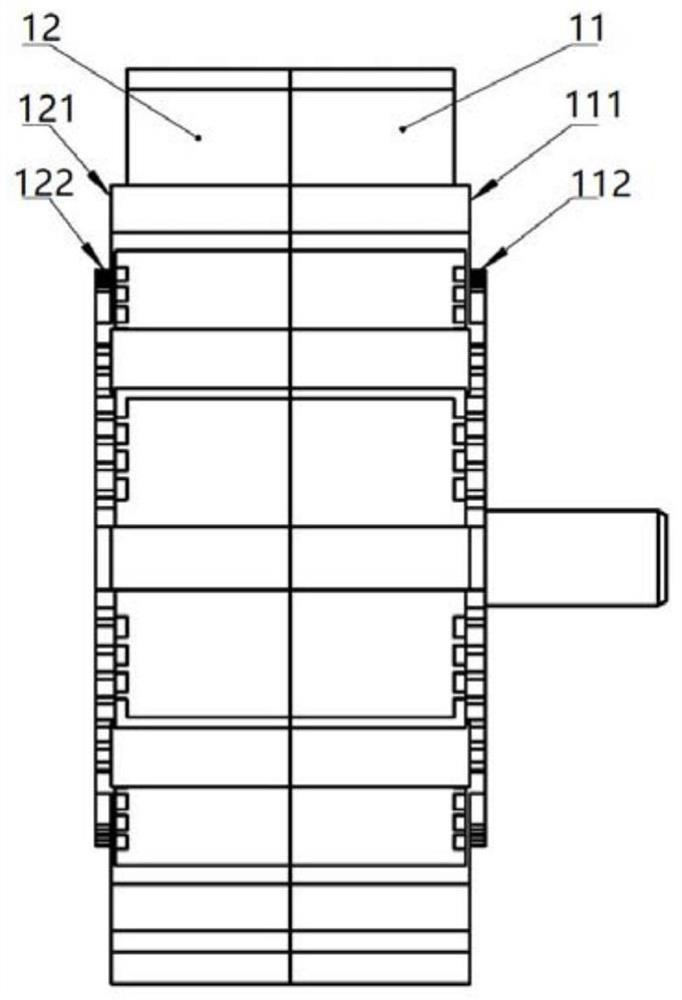

[0066] refer to Figure 7-10 , the present embodiment provides a disc motor with a general installation structure, including a front housing 11, a rear housing 12, a flange 2, at least one connecting assembly 3, wherein the connecting assembly 3 is a bolt 31, And the flange 2 is fixed on the front end 111 of the front shell 11 away from the rear shell 12 .

[0067] Specifically, the front housing 11 has a front end portion 111, and a plurality of front channels 112 arranged at intervals around the edge of the front end portion 111; A rear channel 122, one end of the motor main shaft rotates coaxially on the inner wall of the rear housing 12, and the other end passes through the front housing 11 from the bearing hole 1111 of the front end 111, and the front housing 11 and the rear housing 12 are along the motor. Axially assembled to form the housing 1, so that the front channel 112 or the rear channel 122 can be opposite to each other, the front end 111 and the rear end 121 ar...

Embodiment 2

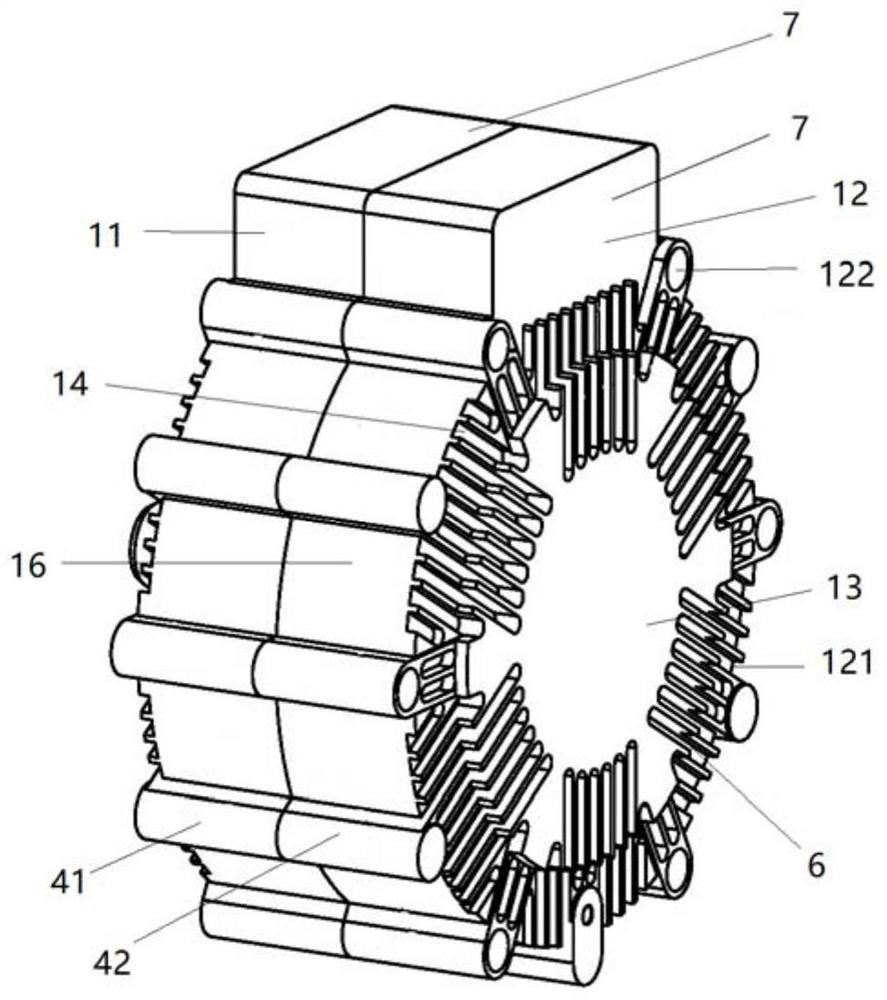

[0070] refer to Figure 11-14 , the present embodiment provides a disc motor with a general installation structure, including a front housing 11, a rear housing 12, a flange 2, at least one connection assembly 3, wherein the connection assembly 3 includes bolts 31 and nuts 32 , and fix the flange 2 on the front end 111 of the front housing 11 away from the rear housing 12 .

[0071] Specifically, the front housing 11 has a front end portion 111, and a plurality of front channels 112 arranged at intervals around the edge of the front end portion 111; There is a rear channel 122, one end of the motor main shaft rotates coaxially on the inner wall of the rear housing 12, and the other end passes through the front housing 11 coaxially from the front end 111, and the front housing 11 and the rear housing 12 are along the axial direction of the motor. Assembled to form the shell 1, so that the front channel 112 or the rear channel 122 can be opposed one by one, the front end 111 an...

Embodiment 3

[0074] refer to Figure 15-18 , the present embodiment provides a disc motor with a general installation structure, including a front housing 11, a rear housing 12, a flange 2, at least one connection assembly 3, wherein the connection assembly 3 is a bolt 31, and fix the flange 2 on the front end 111 of the front shell 11 away from the rear shell 12.

[0075] Specifically, the front housing 11 has a front end portion 111, and a plurality of front channels 112 arranged at intervals around the edge of the front end portion 111; There is a rear channel 122, one end of the motor main shaft rotates coaxially on the inner wall of the rear housing 12, and the other end passes through the front housing 11 coaxially from the front end 111, and the front housing 11 and the rear housing 12 are along the axial direction of the motor. Assembled to form the shell 1, so that the front channel 112 or the rear channel 122 can be opposed one by one, the front end 111 and the rear end 121 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com