Real-time cleaning device for oil-gas pipeline of tire oil refining reaction kettle

A technology for cleaning devices and oil and gas pipelines, applied in the petroleum industry, cleaning hollow objects, chemical/physical processes, etc., can solve problems such as adhesion, affecting pipeline flow, and the inner wall of the pipeline cannot be cleaned in real time, so as to achieve ingenious structure and ensure flow area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

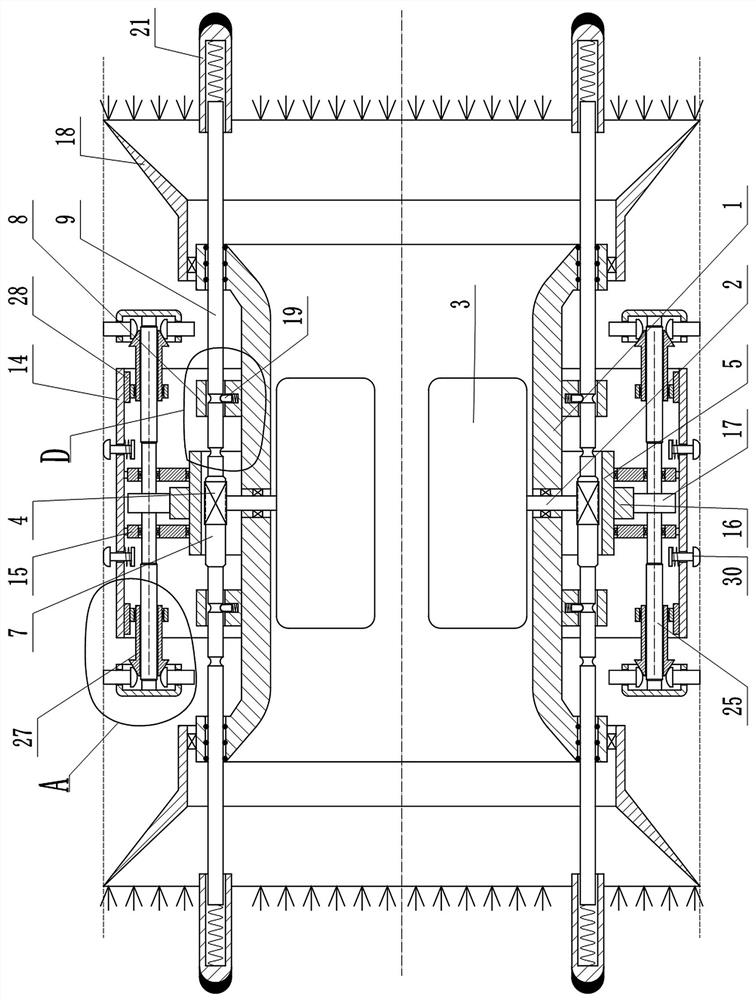

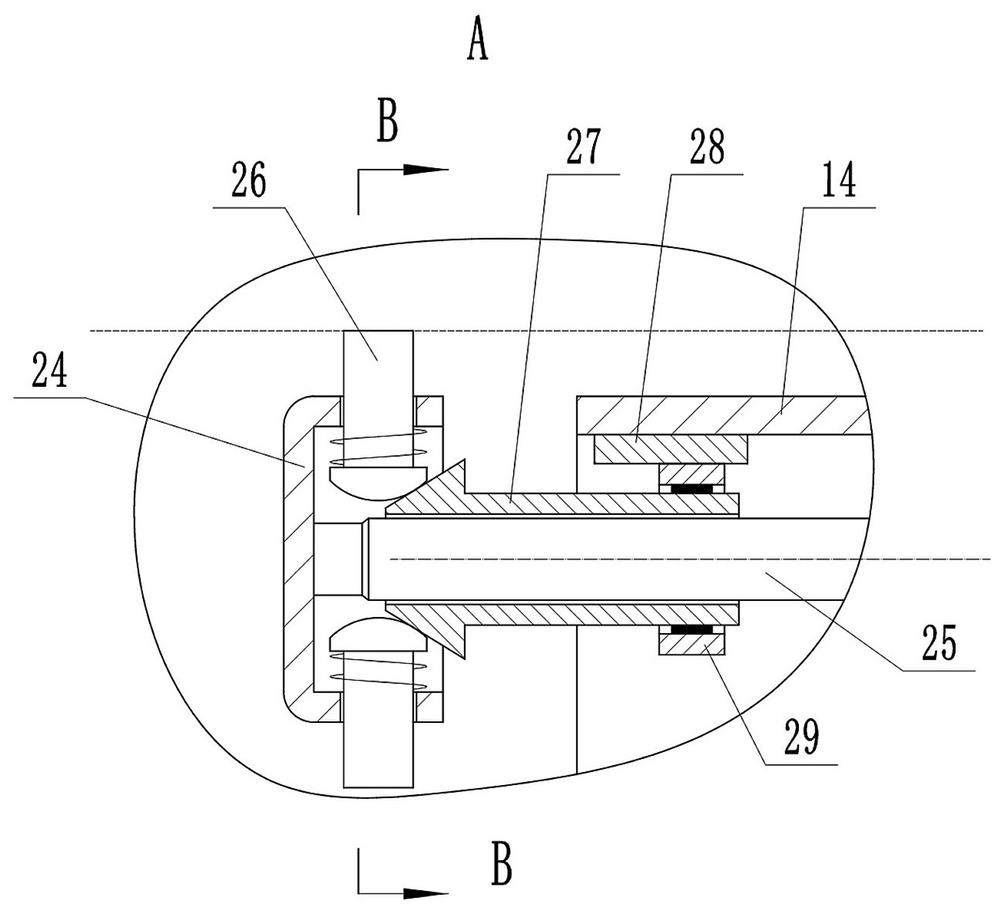

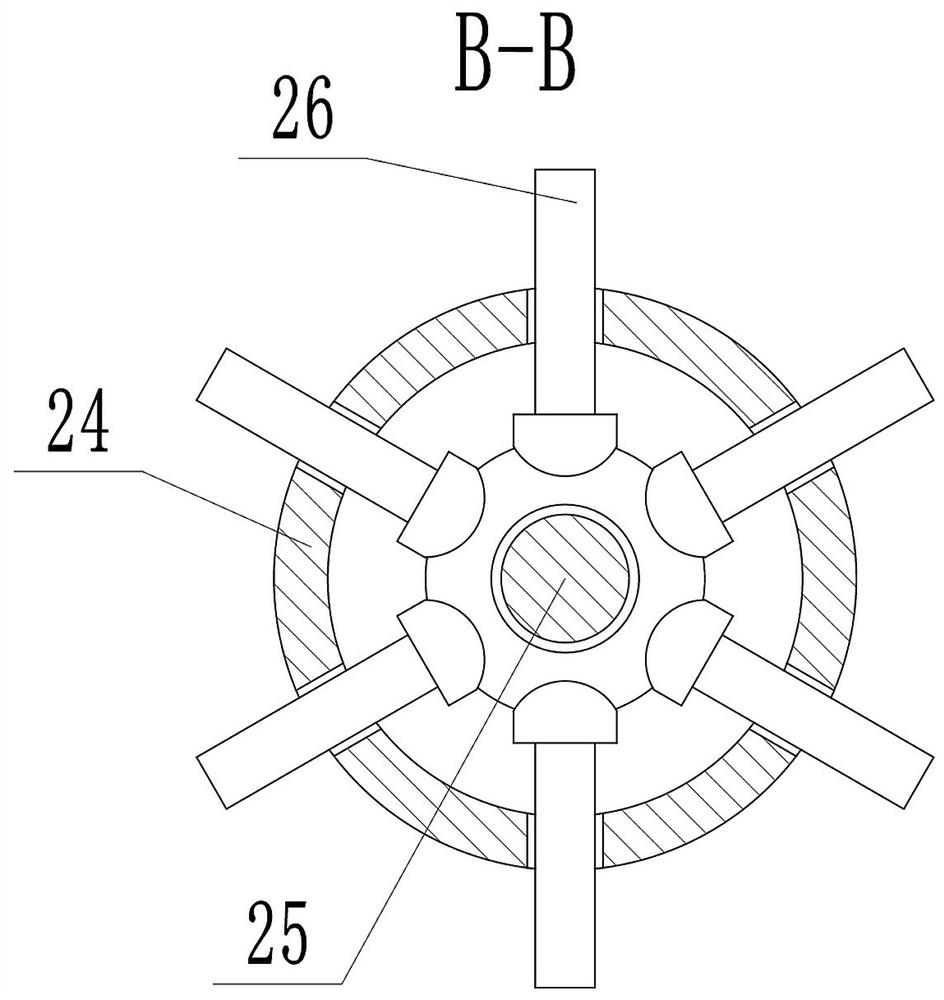

[0020] Depend on Figure 1 to Figure 7 Provided, the present invention comprises a horizontal hollow cylinder 1, a plurality of rotatable rotating shafts 2 run through the side wall of the hollow cylinder 1, and the plurality of rotating shafts 2 are uniformly distributed on the circumference, and there are a plurality of flat plates 3 in the hollow cylinder 1, and the flat plates 3 and The rotating shafts 2 are fixed together in one-to-one correspondence. There is a first gear 4 corresponding to the rotating shaft 2 on the outside of the hollow cylinder 1. The first gear 4 is coaxially fixed with the rotating shaft 2. One side of the first gear 4 is meshed with a Axially arranged rack 7, rack 7 can move left and right, and rack 7 can drive plate 3 to rotate around shaft 2 through first gear 4. There are multiple rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com