Gluing device for carton production line

A gluing device and production line technology, which is applied to the surface coating liquid device, coating, etc., can solve the quality impact of gluing, glue overflow and other problems, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

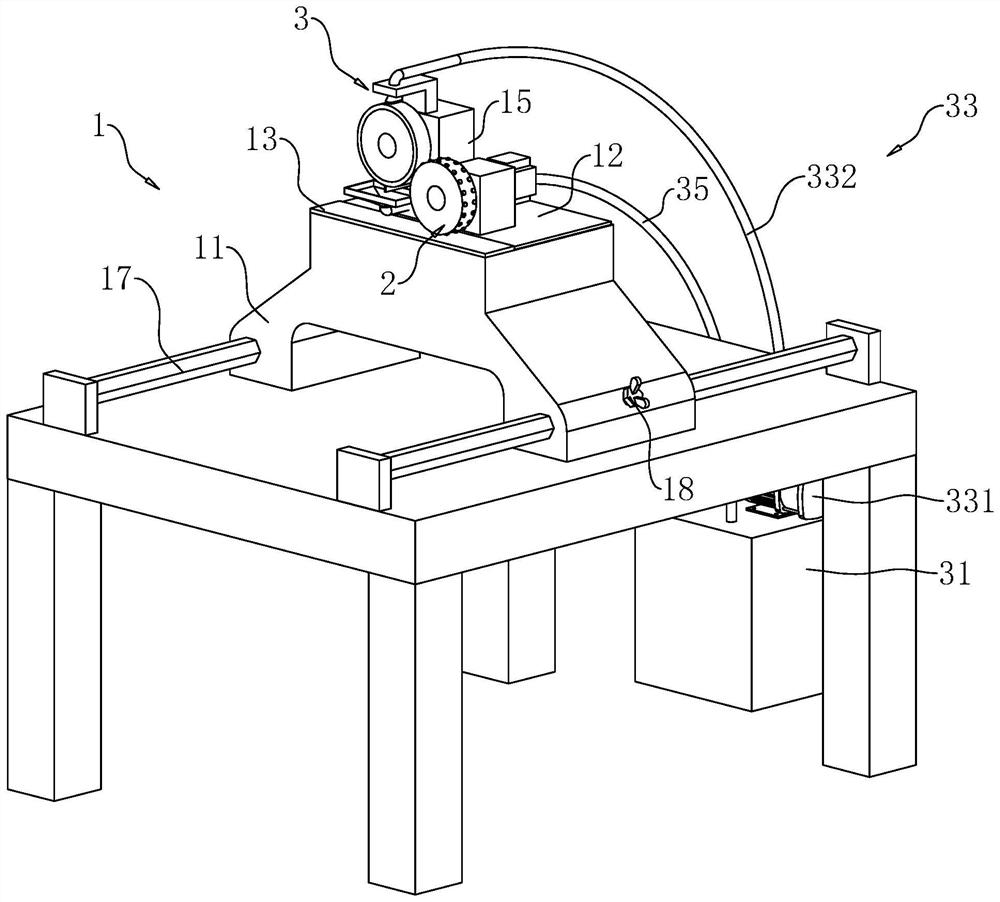

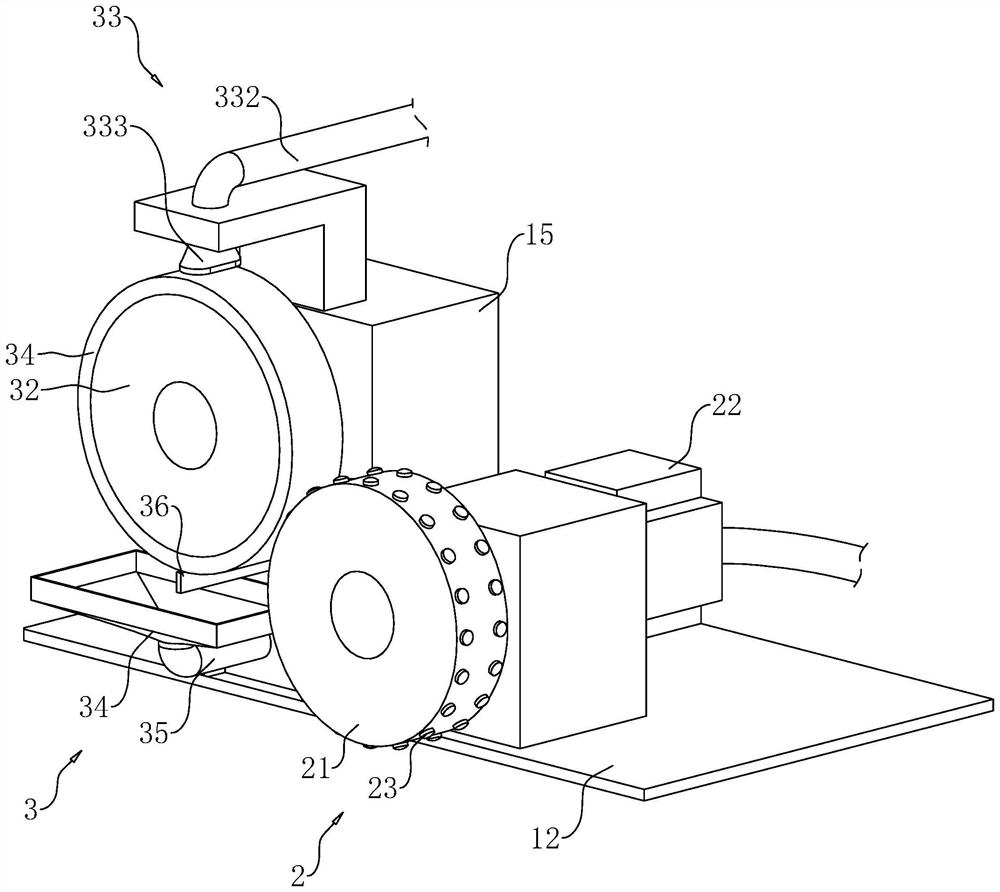

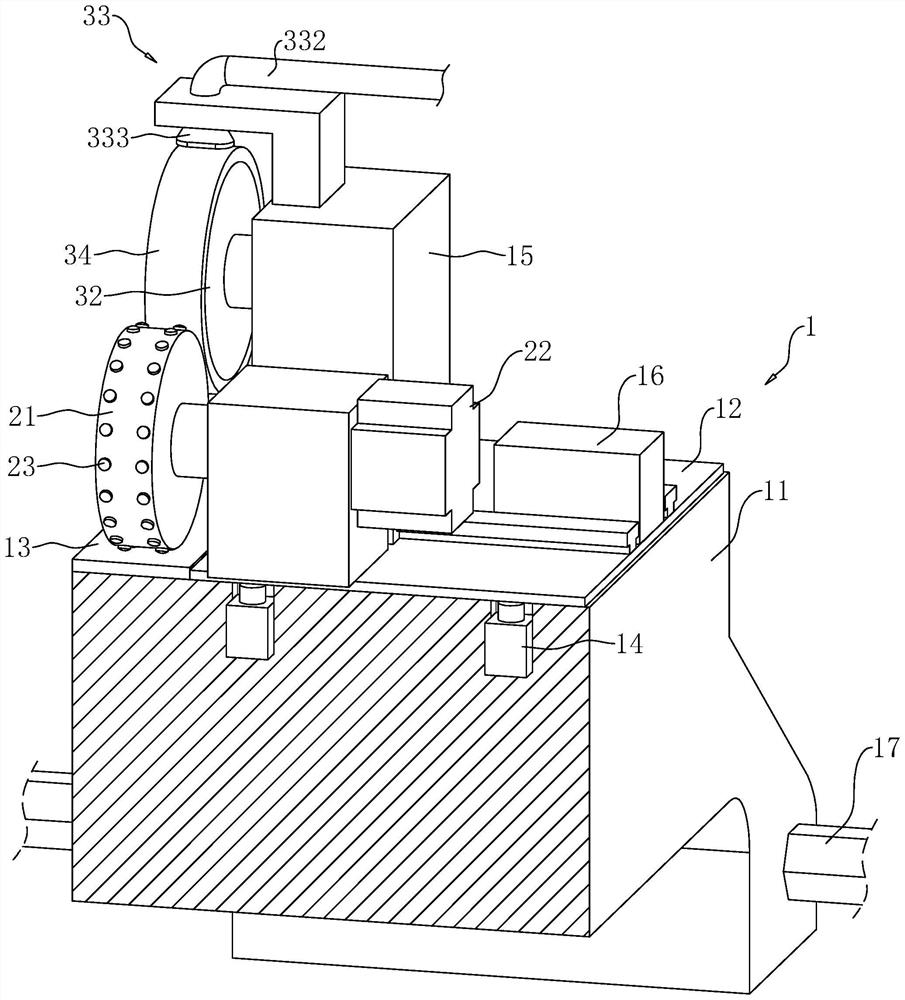

[0035] The following is attached Figure 1-5 The application is described in further detail.

[0036] The embodiment of the present application discloses a gluing device for carton production. The gluing device is installed on the frame of the carton processing production line, and is used to apply glue on the carton to facilitate folding and bonding of the carton; in addition , the gluing device can also be applied to other working conditions that require gluing or other liquids on items, refer to figure 1 with figure 2 , the gluing device includes a mounting assembly 1 arranged on the frame, a gluing assembly 2 arranged on the mounting assembly 1, and a glue supply assembly 3 for delivering glue to the gluing assembly 2; the gluing device passes through the mounting assembly 1 is connected to the production line, and the glue supply component 3 is used to transport the glue to the glue component 2. The production line drives the carton to move. When the carton moves to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com