Display module and preparation method and application thereof

A display module and liquid crystal display technology, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems of small bonding area in BM area, difficulty in die-cutting and construction, and improve bonding efficiency , with reworkability, to solve the effect of narrow width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

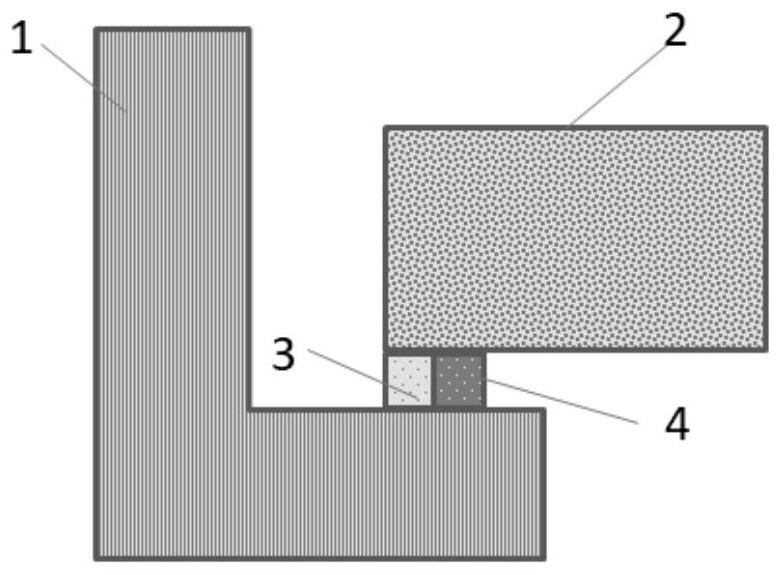

[0046] A display module, its structural schematic diagram is as follows figure 1 As shown, including LCD display 1 (BOE) and frame 2 (Zhuhai Fuji Intelligent Co., Ltd.);

[0047] The liquid crystal display screen and the frame are connected by black UV glue 3 (one-component polyurethane acrylate glue, Japan SEKISUI) and transparent UV glue 4 (one-component polyurethane acrylate glue, Japan SEKISUI);

[0048] The preparation method includes: applying black UV glue and transparent UV glue on the frame through a screw valve needle automatic dispensing machine with plastic steel needles or stainless steel needles, connecting with the LCD screen, using UV and moisture Curing in a dual-curing manner for 24 hours to obtain the display module;

[0049] The glue line width of the transparent UV glue coated is 0.3mm, and the height of the transparent UV glue coated is 0.5mm; the dispensing speed of the transparent UV glue coated is 50mm / s; the black UV glue coated The glue line width ...

Embodiment 2

[0051] A display module, the structure of which is the same as in Embodiment 1, including a liquid crystal display (BOE) and a frame (Zhuhai Fuji Intelligent Co., Ltd.);

[0052] The liquid crystal display screen and the frame are connected by black UV glue (one-component polyurethane acrylate glue, Japan SEKISUI) and transparent UV glue (one-component polyurethane acrylate glue, Japan SEKISUI);

[0053] The preparation method includes: applying black UV glue and transparent UV glue on the frame through a screw valve needle automatic dispensing machine with plastic steel needles or stainless steel needles, connecting with the LCD screen, using UV and moisture Curing in a dual-curing manner for 24 hours to obtain the display module;

[0054] The glue line width of the transparent UV glue coated is 0.2mm, and the height of the transparent UV glue coated is 0.4mm; the dispensing speed of the transparent UV glue coated is 40mm / s; the black UV glue coated The glue line width of th...

Embodiment 3

[0056] A display module, the structure of which is the same as in Embodiment 1, including a liquid crystal display (BOE) and a frame (Zhuhai Fuji Intelligent Co., Ltd.);

[0057] The liquid crystal display screen and the frame are connected by black UV glue (one-component polyurethane acrylate glue, Japan SEKISUI) and transparent UV glue (one-component polyurethane acrylate glue, Japan SEKISUI);

[0058] The preparation method includes: applying black UV glue and transparent UV glue on the frame through a screw valve needle automatic dispensing machine with plastic steel needles or stainless steel needles, connecting with the LCD screen, using UV and moisture Curing in a dual-curing manner for 24 hours to obtain the display module;

[0059] The glue line width of the transparent UV glue coated is 0.4mm, and the height of the transparent UV glue coated is 0.6mm; the dispensing speed of the transparent UV glue coated is 60mm / s; the black UV glue coated The glue line width of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com