A method and device for machining process grooves

A technology of processing technology and process tank, which is applied in the direction of accessory devices, metal processing equipment, electric processing equipment, etc., can solve the problems of affecting the accuracy of the oil tank, poor processing accuracy, and low product qualification rate, so as to improve processing efficiency and accuracy , Improve the effect of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

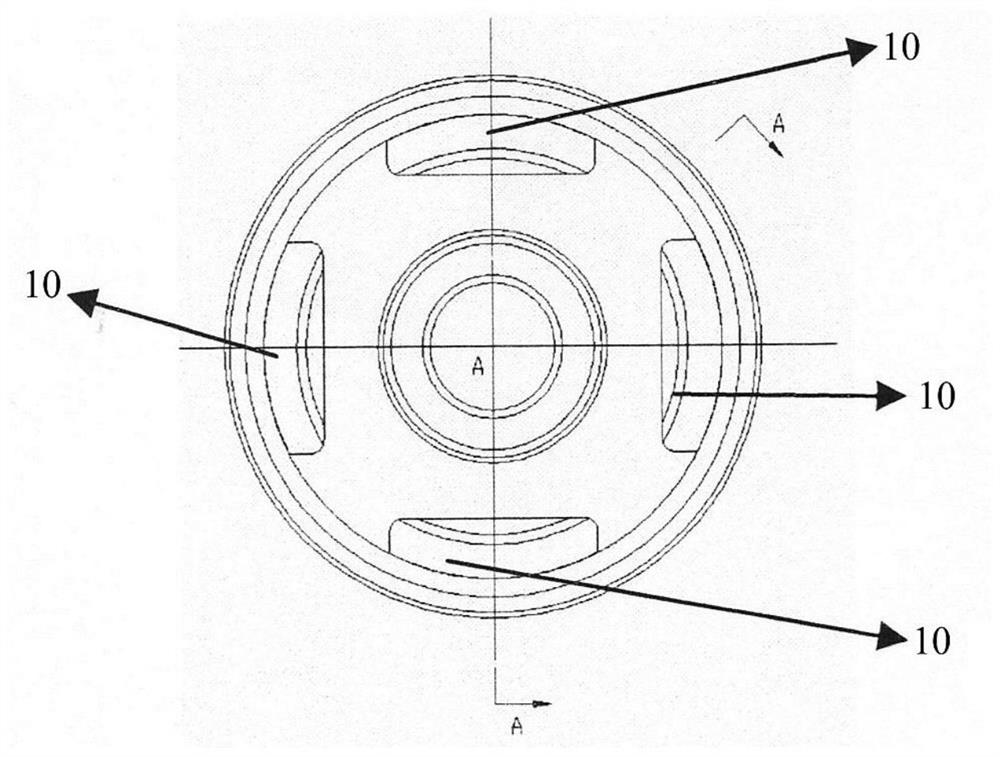

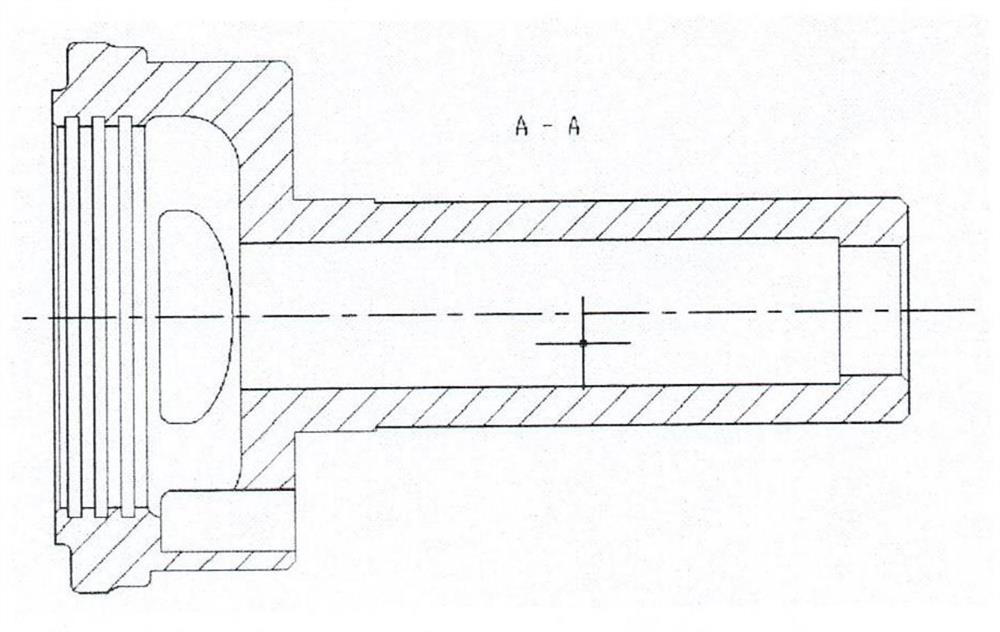

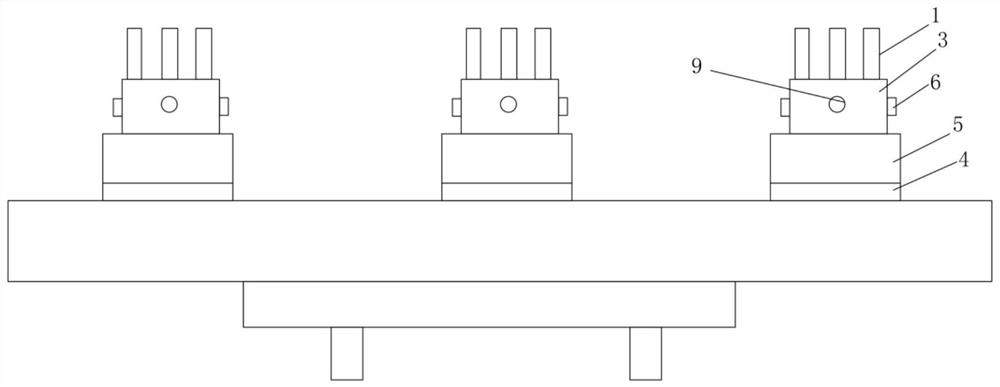

[0037] refer to image 3 , Figure 4 and Figure 5 , a device for processing a groove, comprising a first bottom plate and a second bottom plate, a plurality of positioning holes are set on the first bottom plate, a positioning grating sheet 4 is arranged in the positioning holes, and a positioning sensor 5 is arranged on the positioning grating sheet 4 to locate The sensor 5 is provided with an electrode sheet positioning mechanism 3 to open a through hole slot for installing the process groove forming electrode sheet 1, and a translation mechanism is set on the electrode sheet positioning mechanism 3. The positioning sensor 5 is connected to the input end of the controller, and the output of the controller The terminal is connected to a digital display meter, the top of the positioning sensor 5 is provided with a process groove forming electrode sheet 1, the second base plate is used to fix the part to be processed 7, and the center of the part to be processed 7 on the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com