Fireproof formaldehyde-free plywood and manufacturing method thereof

A production method and plywood technology, applied in the field of plywood, can solve problems such as damage to the health of workers, poor fire resistance, poor fire resistance of plywood, etc., and achieve the effects of scientific and reasonable distribution of raw materials, small thermal conductivity, and reduced quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

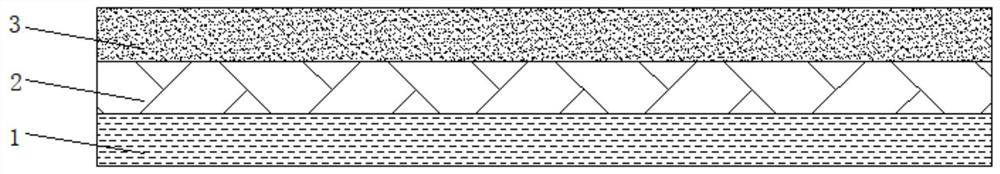

[0049] Example 1, see figure 1 , a fireproof formaldehyde-free plywood and a manufacturing method thereof, comprising three veneers, the three veneers are connected by hot-pressing glue, and the three veneers are a panel 1, a middle panel 2 and a bottom panel 3 from top to bottom, The middle board includes the following components of raw materials: 20 parts of straw slag, 20 parts of bamboo board, 50 parts of rock wool, 10 parts of aluminum hydroxide flame retardant, 1 part of antibacterial agent and 100 parts of glue.

[0050] Further, the preparation of base plate 3 includes the following steps:

[0051] S1, material selection and steaming, selecting plate raw materials, and then performing steaming and softening treatment on the plate raw materials;

[0052] S2, adding the board raw material obtained in step S1 into a heat refiner for fiber separation to obtain basic fibers;

[0053] S3, mixing the basic fiber, asbestos fiber and resin fiber in a ratio of 3:1:1 to form a ...

Embodiment 2

[0074] Example 2, see figure 1 , a fireproof formaldehyde-free plywood and a manufacturing method thereof, comprising three veneers, the three veneers are connected by hot-pressing glue, and the three veneers are a panel 1, a middle panel 2 and a bottom panel 3 from top to bottom, The intermediate board includes the following component raw materials: 30 parts of straw residue, 25 parts of bamboo board, 55 parts of rock wool, 15 parts of aluminum hydroxide flame retardant, 2 parts of antibacterial agent and 120 parts of glue.

[0075] Further, the preparation of the bottom plate 3 includes the following steps:

[0076] S1, material selection and steaming, selecting plate raw materials, and then performing steaming and softening treatment on the plate raw materials;

[0077] S2, adding the board raw material obtained in step S1 into a heat refiner for fiber separation to obtain basic fibers;

[0078] S3, mixing the basic fiber, asbestos fiber and resin fiber in a ratio of 3:1:...

Embodiment 3

[0099] Example 3, see figure 1 , a fireproof formaldehyde-free plywood and a manufacturing method thereof, comprising three veneers, the three veneers are connected by hot-pressing glue, and the three veneers are a panel 1, a middle panel 2 and a bottom panel 3 from top to bottom, The middle board includes the following components of raw materials: 40 parts of straw slag, 30 parts of bamboo board, 60 parts of rock wool, 20 parts of aluminum hydroxide flame retardant, 3 parts of antibacterial agent and 140 parts of glue.

[0100] Further, the preparation of the bottom plate 3 includes the following steps:

[0101] S1, material selection and steaming, selecting plate raw materials, and then performing steaming and softening treatment on the plate raw materials;

[0102] S2, adding the board raw material obtained in step S1 into a heat refiner for fiber separation to obtain basic fibers;

[0103] S3, mixing the basic fiber, asbestos fiber and resin fiber in a ratio of 3:1:1 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com