A kind of manufacturing method of fireproof formaldehyde-free plywood

A production method and technology of plywood, applied in the field of xx, can solve the problems of damage to the health of workers, poor fire resistance of plywood, poor fire performance, etc., and achieve the effect of improving surface finish, reducing quality, and small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

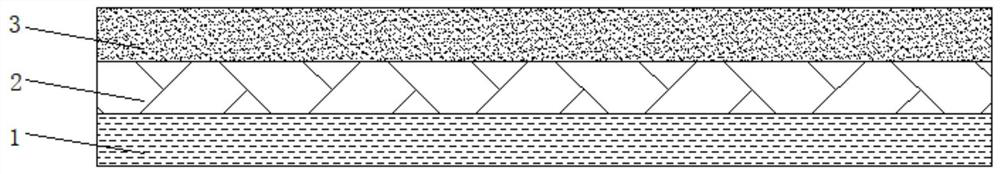

[0049] Example 1, see figure 1 , a method for making fire-resistant formaldehyde-free plywood, comprising three boards, the three boards are connected by glue hot-pressing, the three boards are a panel 1, a middle board 2 and a bottom plate 3 sequentially from top to bottom, and the middle board includes the following The ingredients are composed of 20 parts of straw slag, 20 parts of bamboo board, 50 parts of rock wool, 10 parts of aluminum hydroxide flame retardant, 1 part of antibacterial agent and 100 parts of glue.

[0050] Further, the preparation of the bottom plate 3 includes the following steps:

[0051] S1, select materials for cooking, select plate raw materials, and then perform cooking and softening treatment on the plate raw materials;

[0052] S2, adding the plate material obtained in step S1 into a thermal mill for fiber separation to obtain basic fibers;

[0053] S3, mix the basic fibers, asbestos fibers and resin fibers in a ratio of 3:1:1 to form mixed fib...

Embodiment 2

[0074] Example 2, see figure 1 , a method for making fire-resistant formaldehyde-free plywood, comprising three boards, the three boards are connected by glue hot-pressing, the three boards are a panel 1, a middle board 2 and a bottom plate 3 in sequence from top to bottom, and the middle board is Including the following components to form raw materials, 30 parts of straw slag, 25 parts of bamboo board, 55 parts of rock wool, 15 parts of aluminum hydroxide flame retardant, 2 parts of antibacterial agent and 120 parts of glue.

[0075] Further, the preparation of the bottom plate 3 includes the following steps:

[0076] S1, select materials for cooking, select plate raw materials, and then perform cooking and softening treatment on the plate raw materials;

[0077] S2, adding the plate material obtained in step S1 into a thermal mill for fiber separation to obtain basic fibers;

[0078] S3, mix the basic fibers, asbestos fibers and resin fibers in a ratio of 3:1:1 to form mix...

Embodiment 3

[0099] Example 3, see figure 1 , a method for making fire-resistant formaldehyde-free plywood, comprising three boards, the three boards are connected by glue hot-pressing, the three boards are a panel 1, a middle board 2 and a bottom plate 3 in sequence from top to bottom, and the middle board is It consists of the following raw materials: 40 parts of straw slag, 30 parts of bamboo board, 60 parts of rock wool, 20 parts of aluminum hydroxide flame retardant, 3 parts of antibacterial agent and 140 parts of glue.

[0100] Further, the preparation of the bottom plate 3 includes the following steps:

[0101] S1, select materials for cooking, select plate raw materials, and then perform cooking and softening treatment on the plate raw materials;

[0102] S2, adding the plate material obtained in step S1 into a thermal mill for fiber separation to obtain basic fibers;

[0103] S3, mix the basic fibers, asbestos fibers and resin fibers in a ratio of 3:1:1 to form mixed fibers;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com