Thermoplastic elastomer extruding and pelletizing device

A thermoplastic elastomer and pelletizing technology, applied in the field of pelletizing equipment, can solve the problems of difficult maintenance and easy wear, and achieve the effects of reducing maintenance costs, reducing wear, and reducing the frequency of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

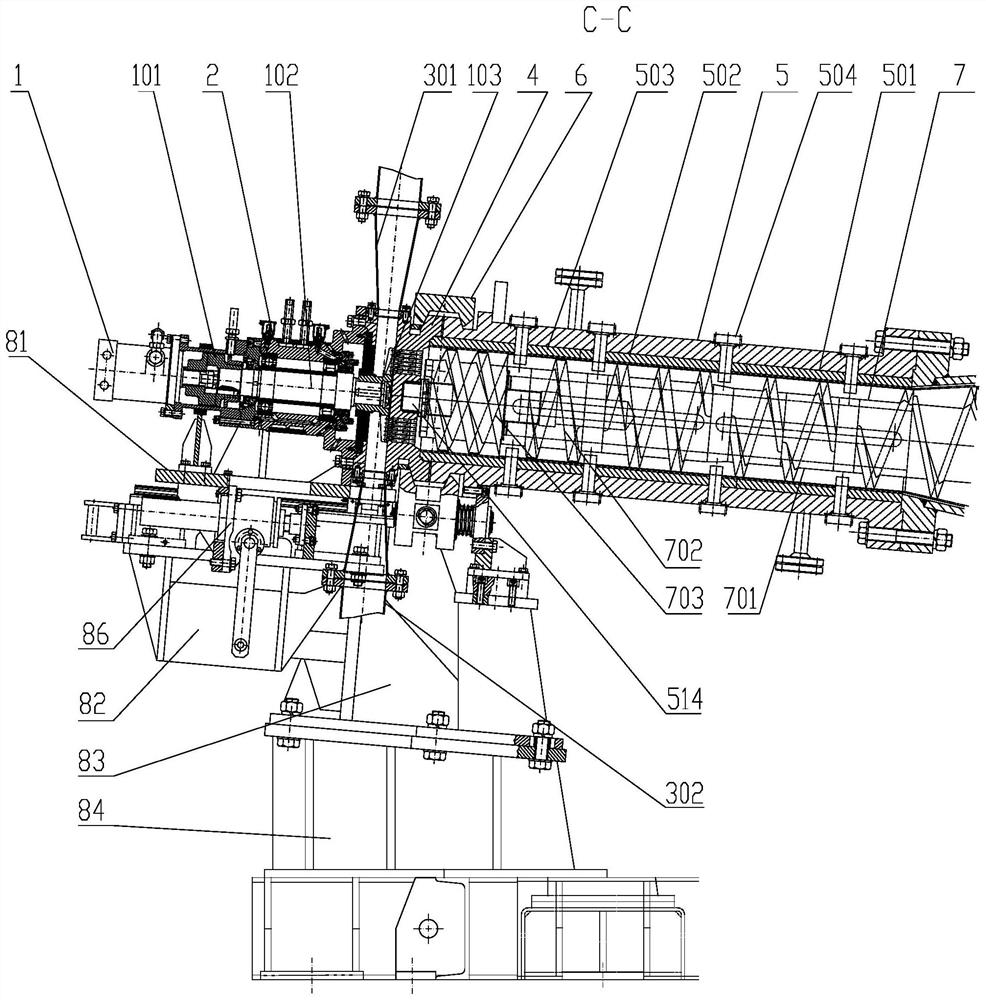

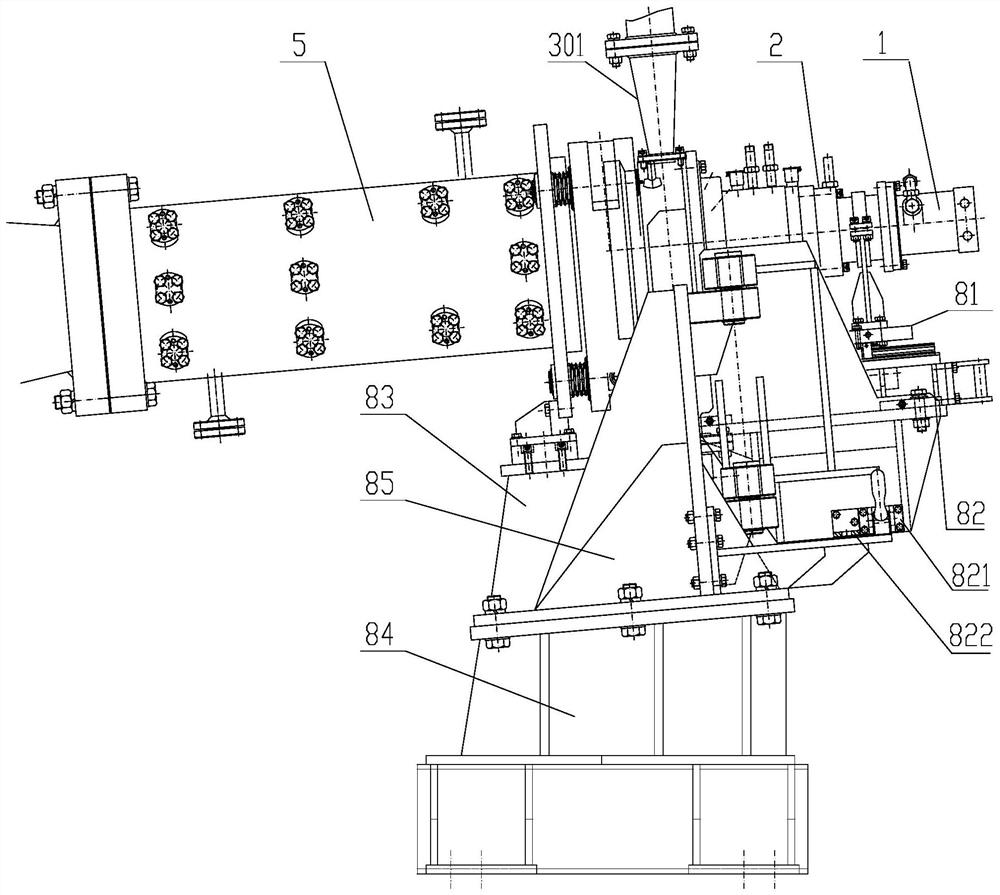

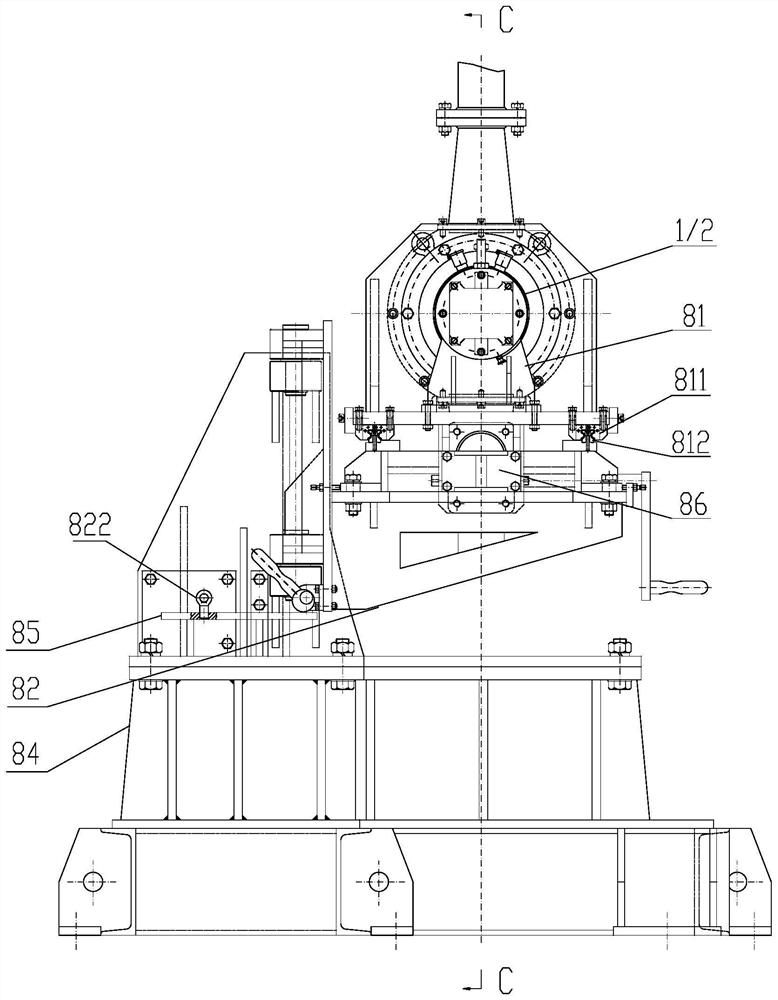

[0051] see in conjunction Figure 1-4 , a thermoplastic elastomer extrusion pelletizing device in the illustration is a specific embodiment of the present invention, specifically including a motor 1, a coupling 101, a cutter shaft 102, a cutter 103, a bearing seat 2, a discharge Air inlet pipe 301, discharge air pipe 302, template 4, extrusion cylinder 5, clamping mechanism 6, conveying screw 7, guide rail seat 81, first bracket 82, cylinder fixing seat 83, base 84, third bracket 85 and other components. Wherein the motor 1, the bearing housing 2, the template 4 and the extrusion cylinder 5 are assembled along the transverse direction, the extrusion cylinder 5 is the extruding component of the device, and the conveying screw 7 is assembled inside the extrusion cylinder 5, and the raw material is extruded from the template 4 Extrusion through the hole, the motor 1 and the bearing seat 2 constitute the pelletizing assembly of the device, and the continuously extruded raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com