A kind of fishing boat positioning buoy

A technology of fishing boats and buoys, which is applied in the field of buoys, can solve the problems of affecting the positioning function and the large turning radius of buoys, and achieve the effects of improving safety, improving efficiency, and efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

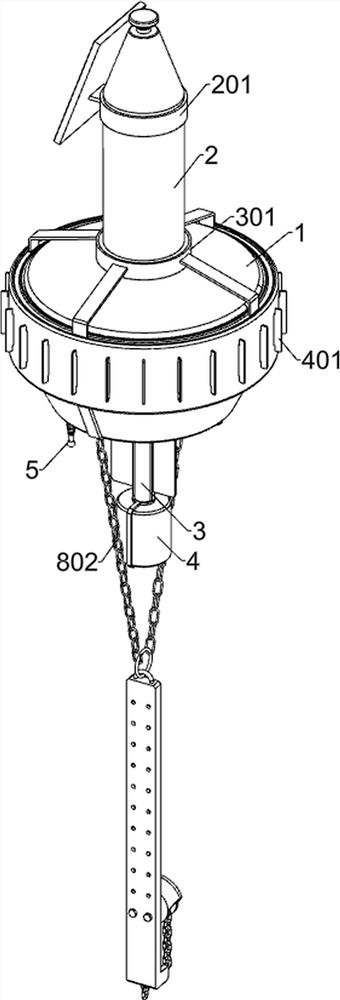

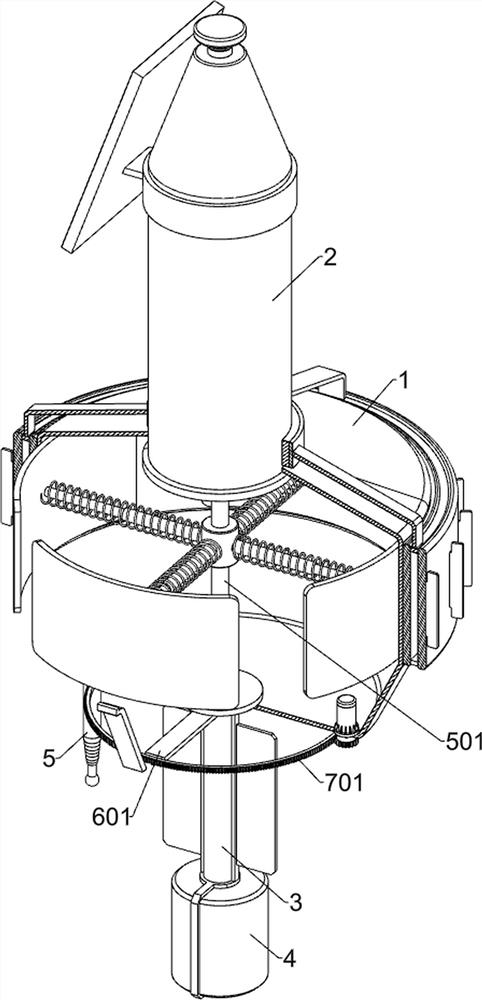

[0030] A fishing boat positioning buoy, such as Figure 1-5 with Figure 8-10 , including a buoy 1, a top column 2, a first connecting rod 3, a counterweight 4, a detector 5, a warning assembly, a first buffer assembly, a second buffer assembly and an adjustment assembly; The lower part of the buoy 1 is fixedly connected with the first connecting rod 3; the lower end of the first connecting rod 3 is fixedly connected with the counterweight 4; A warning assembly is installed on the upper part of the top column 2; a first buffer assembly is installed on the lower part of the top column 2, and the first buffer assembly is located outside the buoy 1; a second buffer assembly is installed inside the buoy 1; the lower side of the top column 2 and the second buffer assembly The adjustment assembly is installed on the lower side of the buoy 1, and the adjustment assembly is located outside the first connecting rod 3.

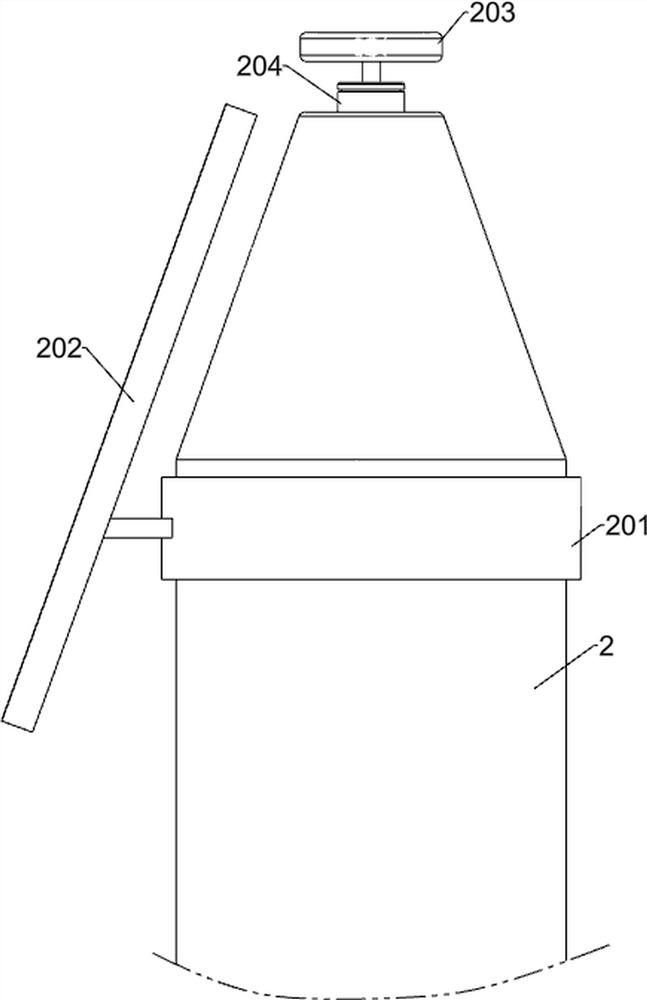

[0031] The warning assembly includes a connecting frame 201, a s...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 1-2 with Figure 6-7 As shown, it also includes a first scraping assembly, the first scraping assembly is installed on the first buffer assembly, the first scraping assembly includes a first resistance plate 401 and a first scraper 402; the outer ring surface of the rubber ring 303 A plurality of first resistance plates 401 are fixed in a circular array; two first scrapers 402 are fixed on the underside of the rubber ring 303 ; both first scrapers 402 are in contact with the buoy 1 .

[0040] It also includes a second scraping assembly, the second scraping assembly is installed on the first connecting rod 3, and the second scraping assembly includes a second scraping plate 601, a scraping rod 602, a second resistance plate 603 and a second linkage frame 604; the upper part of the first connecting rod 3 is rotatably connected with the second scraper 601; the lower side of the second scraper 601 is fixedly connected with two scr...

Embodiment 3

[0043] On the basis of Example 2, such as Figure 1-2 with Figure 7 As shown, a power generation assembly is also included, and the power generation assembly is installed on the upper part of the second scraper assembly. The power generation assembly includes a gear ring 701, a gear 702 and a generator 703; the outer side of the second scraper 601 is welded with a gear ring 701; The right part is equipped with a generator 703, and the output end of the lower part of the generator 703 passes through the buoy 1, and the output end of the lower part of the generator 703 is connected to the buoy 1 in rotation; the output end of the lower part of the generator 703 is fixedly connected with a gear 702, and the gear 702 is located Below the buoy 1; the gear 702 meshes with the gear ring 701.

[0044] When the water flow drives the second scraper 601 to rotate, the second scraper 601 drives the gear ring 701 to rotate, the gear ring 701 drives the gear 702 to rotate, and the gear 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com