High-strength regenerated ceramsite composite prefabricated product

A high-strength, prefabricated technology, applied in the production of ceramic products, clay products, ceramic materials, etc., can solve the problems that the mechanical properties are difficult to meet the standards, the performance of recycled materials is not stable enough, and affect the popularization and application, etc., to achieve excellent mechanical properties and structure Stability, excellent bonding effect and strengthening performance, comprehensive and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

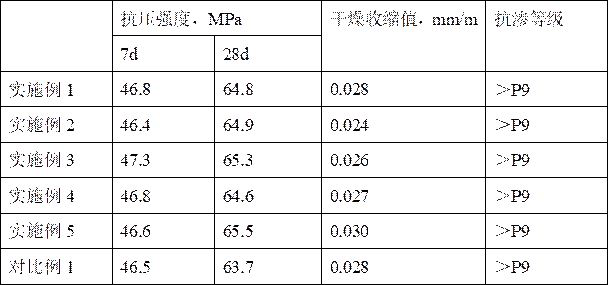

Examples

Embodiment 1

[0022] A high-strength recycled ceramsite composite prefabricated product, including the following component raw materials: cementitious material, recycled ceramsite, aggregate, water reducing agent, mixing water, wherein the density of recycled ceramsite is 388kg / m3, and the particle size is 2-10mm, cylinder compressive strength is 3.46MPa.

[0023] The high-strength recycled ceramsite composite prefabricated product has the parts by weight of each component: 65 parts of cementitious material, 26 parts of recycled ceramsite, 75 parts of aggregate, 3 parts of water reducing agent, and 50 parts of mixing water.

[0024] Ordinary Portland cement is used as the cementing material; natural sandstone is used as the aggregate, and the ratio of coarse aggregate to fine aggregate is 4.2:5.8; the superplasticizer is selected from high-efficiency polycarboxylate superplasticizer.

[0025] The particle size D50 of regenerated ceramsite is 4.3mm.

[0026] The regenerated ceramsite includ...

Embodiment 2

[0029] A high-strength recycled ceramsite composite prefabricated product, including the following component raw materials: cementitious material, recycled ceramsite, aggregate, water reducing agent, and mixing water, wherein the recycled ceramsite has a density of 402kg / m3 and a particle size of 2-10mm, cylinder compressive strength is 3.76MPa.

[0030] The high-strength recycled ceramsite composite prefabricated product has the parts by weight of each component: 60 parts of cementitious material, 30 parts of recycled ceramsite, 80 parts of aggregate, 4 parts of water reducing agent, and 50 parts of mixing water.

[0031] Ordinary Portland cement is used as the cementing material; natural sandstone is used as the aggregate, and the ratio of coarse aggregate to fine aggregate is 4.0:6.0; the superplasticizer is selected from high-efficiency polycarboxylate superplasticizer.

[0032] The particle size D50 of regenerated ceramsite is 4.65mm.

[0033] The regenerated ceramsite i...

Embodiment 3

[0036] A high-strength recycled ceramsite composite prefabricated product, including the following component raw materials: cementitious material, recycled ceramsite, aggregate, water reducing agent, mixing water, wherein the density of recycled ceramsite is 392.5kg / m3, and the particle size is It is 2-10mm, and the cylinder compressive strength is 3.62MPa.

[0037] The high-strength recycled ceramsite composite prefabricated product has the parts by weight of each component: 50 parts of cementitious material, 20 parts of recycled ceramsite, 70 parts of aggregate, 2 parts of water reducing agent, and 42 parts of mixing water.

[0038] As a further preference of the present invention, ordinary portland cement is selected as the cementitious material; natural sandstone is selected as the aggregate, and the ratio of coarse aggregate to fine aggregate is 3.8:6.2; and high-efficiency polycarboxylate superplasticizer is selected as the water reducing agent.

[0039] The particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com