Induction type seamless underwear circular knitting machine and method for controlling fabric traction force

A seamless underwear and inductive technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of fabric coil appearance differences, uneven pulling force, broken needles, etc. The pulling force is uniform and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

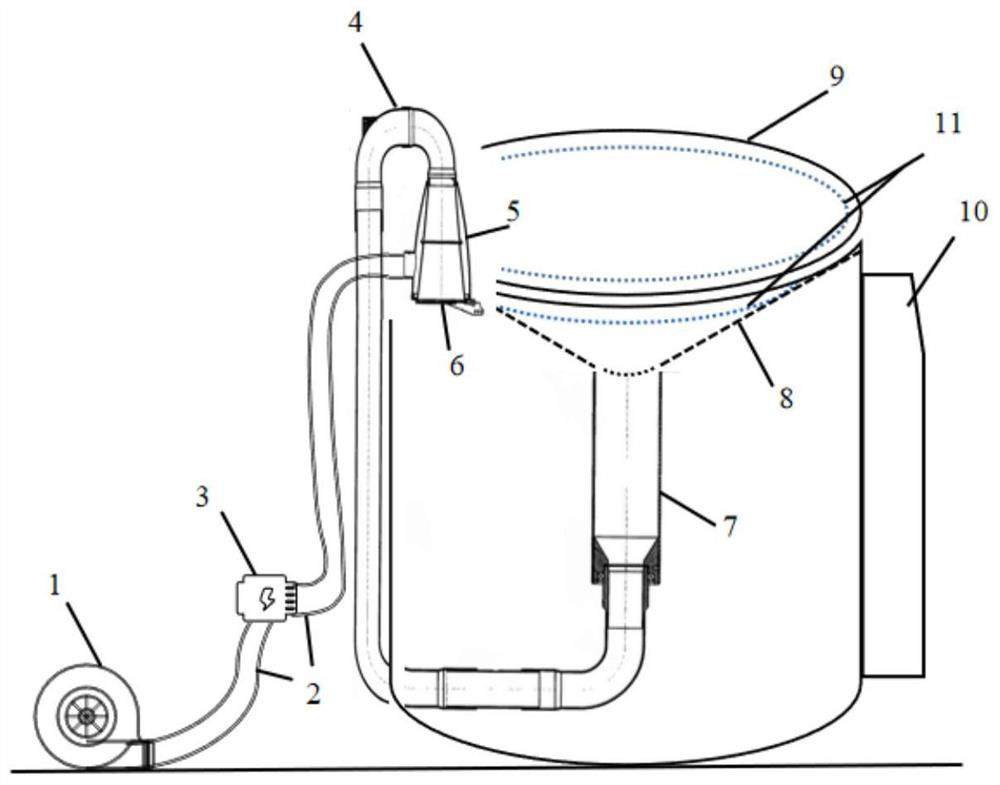

[0060] This embodiment provides an inductive pulling device for a circular knitting machine with uniform tension and seamless underwear. Take the pulling device of Santoni TOP-2 seamless single jacquard underwear circular machine as an example, the specific parameters are: machine number E28; needle number 1344; barrel diameter 15 inches. like figure 1 As shown, the seamless underwear circular machine adopts the suction negative pressure pulling method. When weaving, the suction motor device starts to work, and the damper controller driven by the stepping motor provides the pulling force to pull the clothes from the feeding port. Pull to the outlet bell mouth, and different lengths of clothing fabrics are not uniformly pulled, and there may be problems such as uneven clothing appearance.

[0061] This embodiment provides an induction-type seamless underwear circular machine, such as figure 1 As shown, the underwear circular machine includes a main body, a pulling device, a...

Embodiment 2

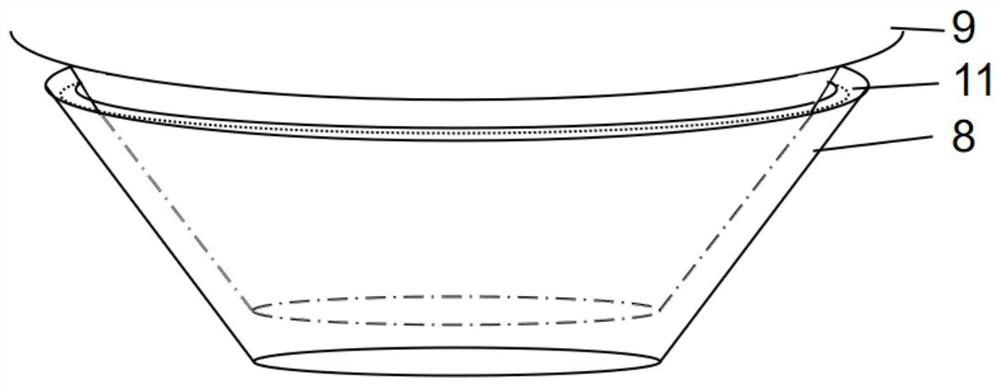

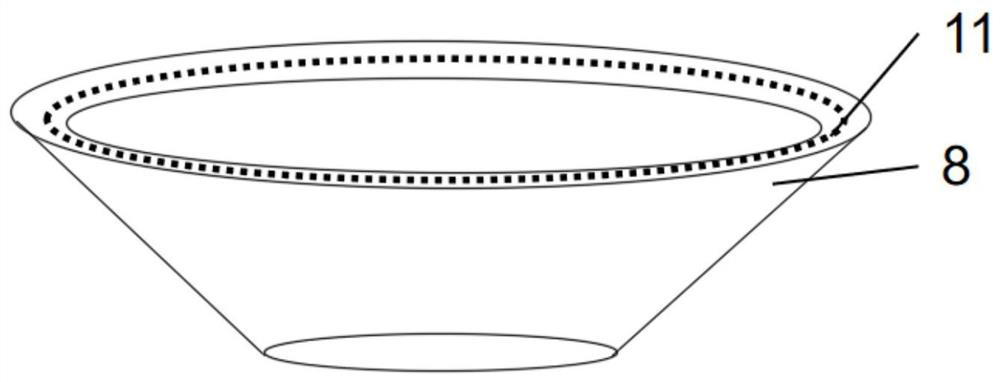

[0070] This embodiment provides an inductive pulling device for a circular knitting machine with uniform tension. like Figure 4 It is shown that the induction device 11 of the pulling system of the seamless underwear circular machine is located at the wall opening of the winding drum 8 and the bottom of the half disk 9, and the induction device of the winding drum 8 and the half disk 9 senses the pairing of different fabrics. The pressure in its vertical direction works. When weaving high-elastic and special-weave fabrics, the fabrics will have weaving problems such as excessive shrinkage and wrinkles, or non-stretching and accumulation in the gap at the bottom of the pan. In this embodiment, induction devices are provided on both the needle cylinder and the half plate, Figure 5 The induction device at the bottom of the half disk 9 is shown. When weaving this type of fabric, the fabric tends to shrink severely and become wrinkled. The negative pressure of the air suction p...

Embodiment 3

[0072] This embodiment provides an inductive pulling device for uniform tension seamless underwear circular knitting machine. The negative pressure x of the suction unit is about 60.0kpa-70.0kpa under normal conditions, and two kinds of fine denier fibers or ultrafine denier fibers are used. When it is used as raw material, the fabric is very light and thin, and the suction negative pressure has little pull on the fabric, and it is not easy to capture the pressure change in the vertical direction of the cylinder wall, which requires an extremely sensitive sensing device. Induction devices (a, b, c, d, e) are provided at different diameters, as shown in Fig. 6(a) and Fig. 6(b). During weaving, the sensing device at point a senses the fabric, and feeds back to the control system to control the suction unit’s 1st level of strength (+20.0kpa). As the fabric continues to weave, the fabric is still relatively light and thin, but the fabric becomes longer, and the negative pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com